Universal bracket for assembling inertial measurement device

An inertial measurement device and universal support technology, which is applied in directions such as navigation through speed/acceleration measurement, can solve the problems of changing surface conditions and difficult support, and achieve the effect of cost saving and stable and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

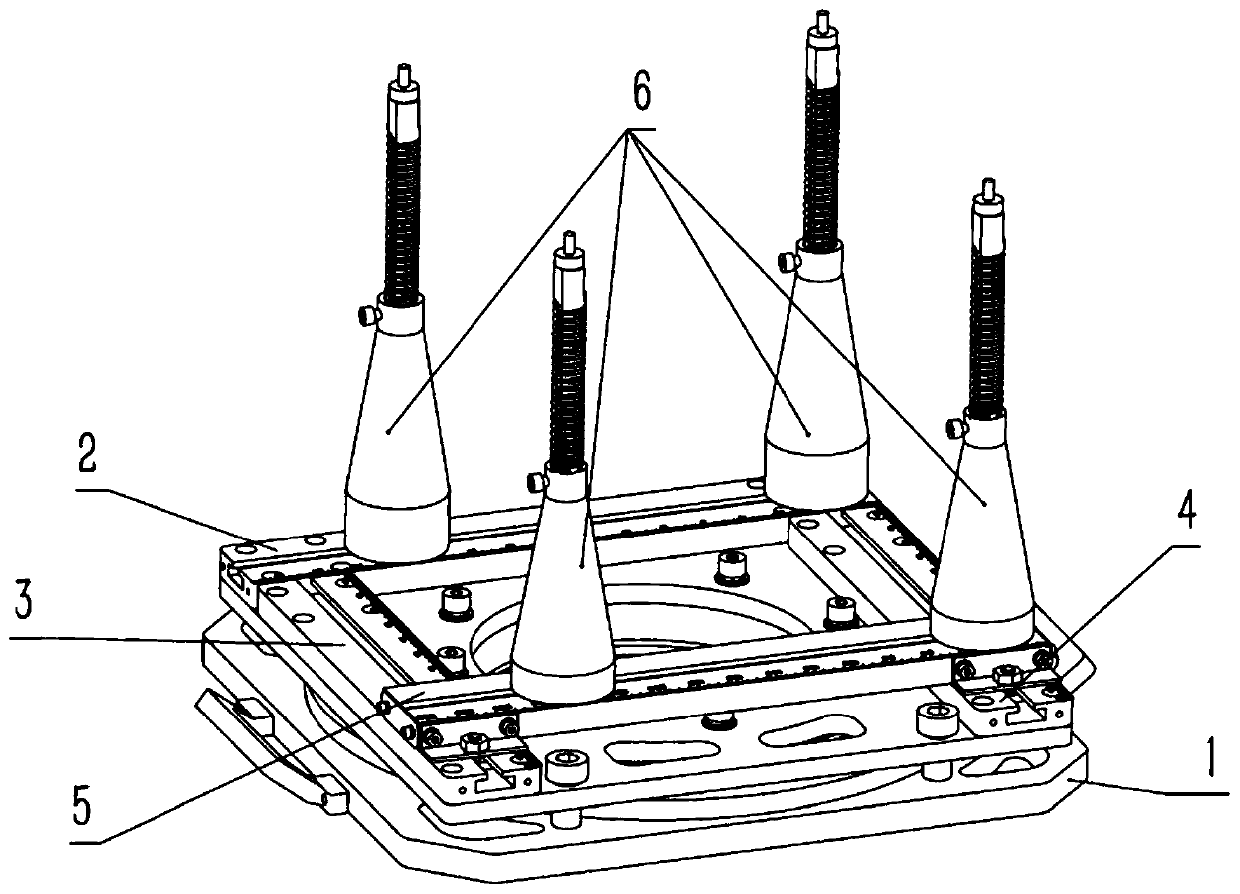

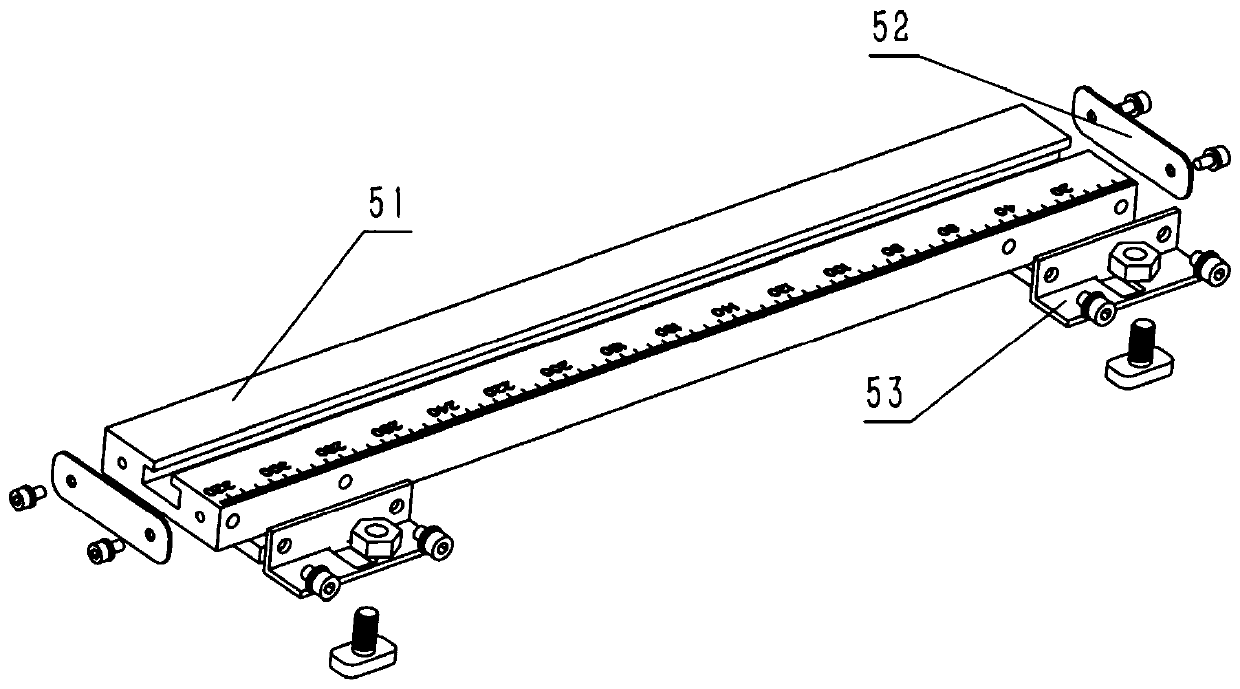

[0027] A universal bracket for the assembly of inertial measurement units such as figure 1 As shown, it is composed of the installation substrate assembly 1, the first guide rail 2, the second guide rail 3, the third guide rail 4, the fourth guide rail 5, and the assembly pillar 6. By combining the first guide rail 2, the second guide rail 3, and the third guide rail 4. The fourth guide rail 5 is arranged on different substrates of the installation substrate assembly 1, and the mounting support 6 is arranged on the uppermost installation substrate, so that the horizontal dimension can be adjusted by sliding the guide rail according to the specific size of the inertial measurement device to be connected. The longitudinal dimension is adjusted through the expansion and contraction of the assembly pillar 6, and finally the device support adaptation is completed.

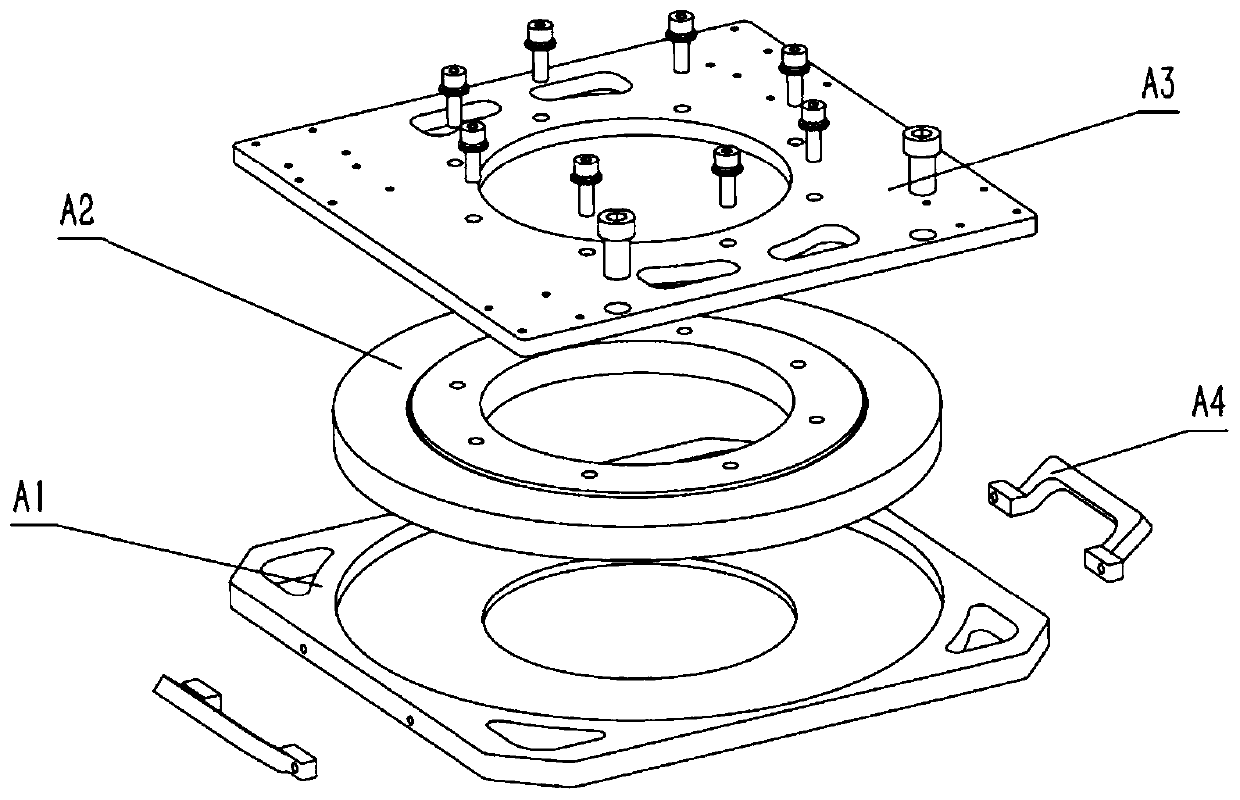

[0028] Among them, such as figure 2 As shown, the installation substrate assembly 1 specifically includes the insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Telescopic length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com