Winding structure of mechanical watch

A mechanical watch, an integrated technology, applied to mechanically driven clocks, clockwork ratchet mechanisms, clocks, etc., can solve the problems of watch winding effort, winding feeling tight, and unable to twist, so as to reduce friction and reduce friction. Torque, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

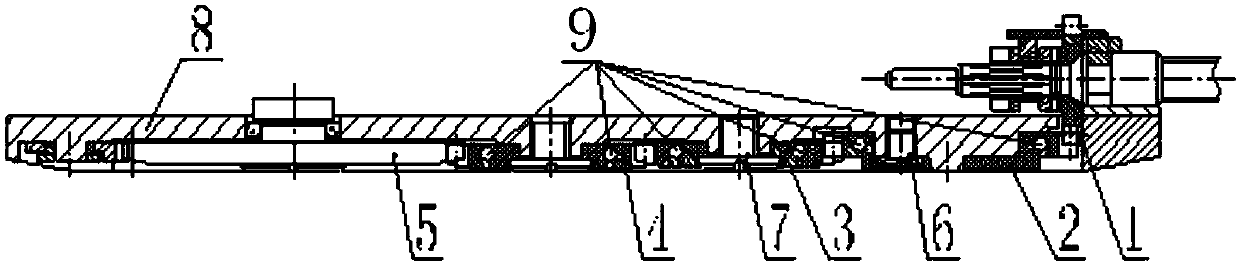

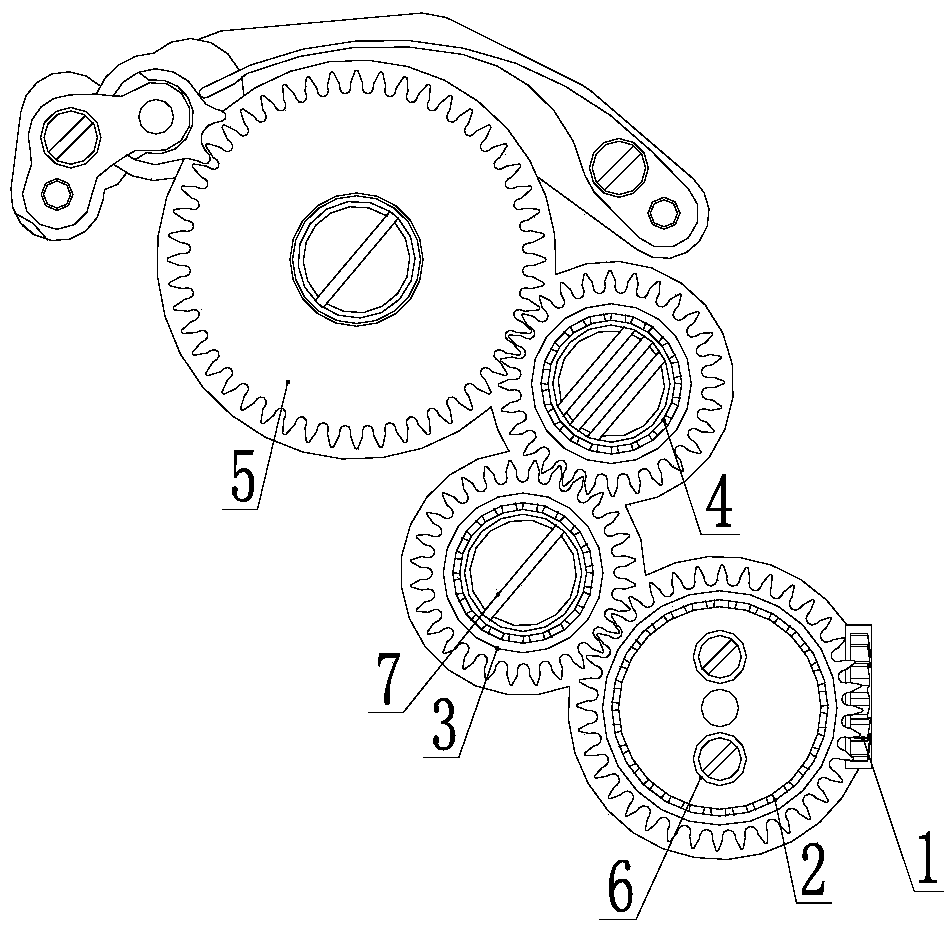

[0023] like figure 1 and figure 2 As shown, a winding structure of a mechanical watch of the present invention includes a vertical wheel 1, a winding wheel part, a winding intermediate wheel part, a winding ratchet 5 and a splint 8; the winding wheel part and the winding intermediate wheel part can be both Install the bearing part or the winding wheel part and the winding idler part to install the bearing part to form the winding wheel bearing assembly and the winding idler bearing assembly; the winding wheel part, the winding idler part and the winding ratchet 5 are installed on the splint 8. The winding idler part includes 1-4 winding idler bearing assemblies.

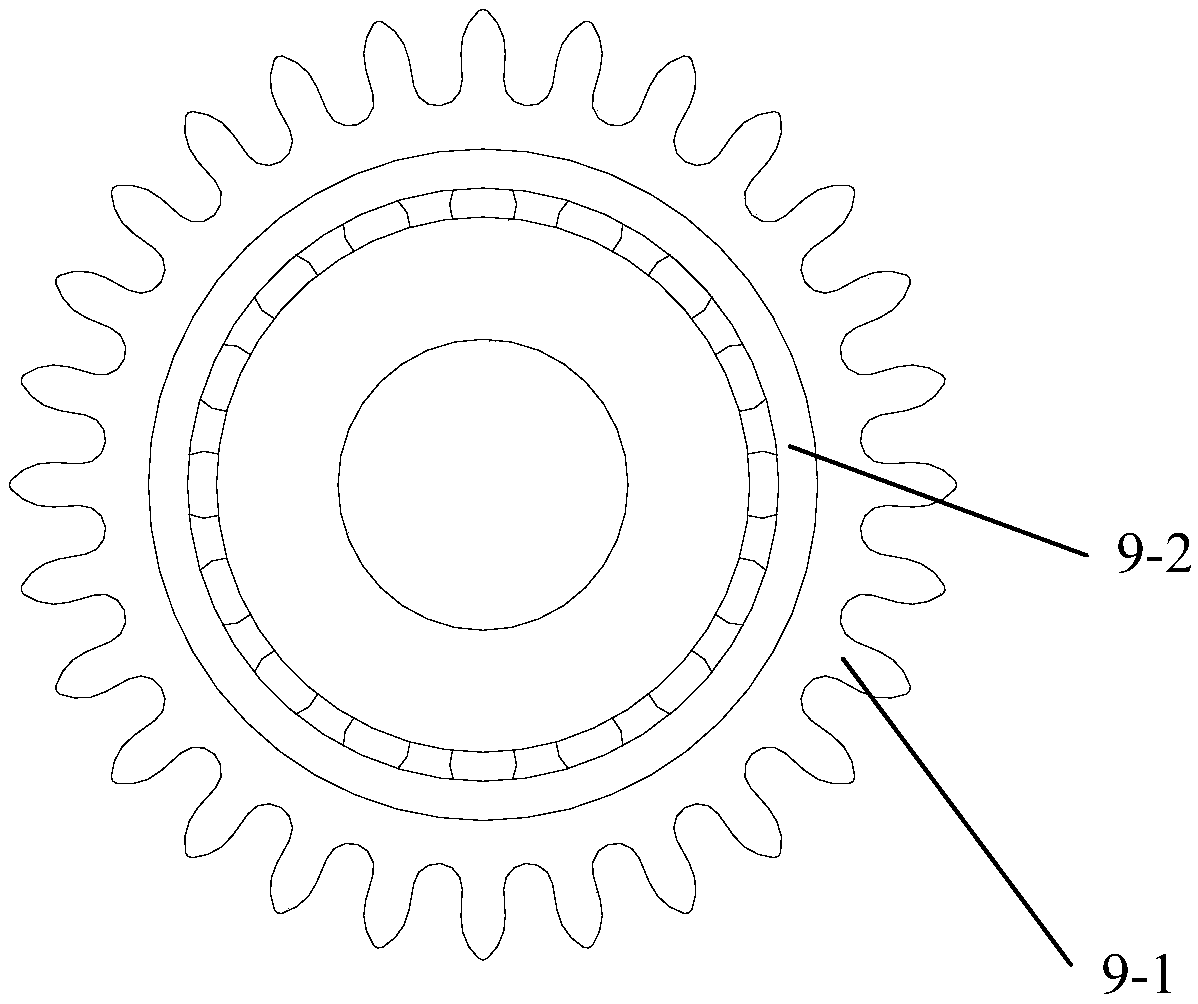

[0024] like image 3 and Figure 4 As shown, here we take two winding idler bearing assemblies as an example, the upper winding idler bearing assembly includes an integrated uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com