Modular controllable time-delay triggering device

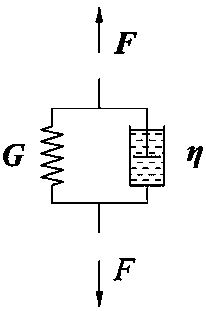

A time-delayed triggering and modularization technology, applied in emergency protection devices, electrical components, electrical switches, etc., can solve problems such as high working environment requirements, open circuit, short circuit, etc., and achieve the effect of reasonable design and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

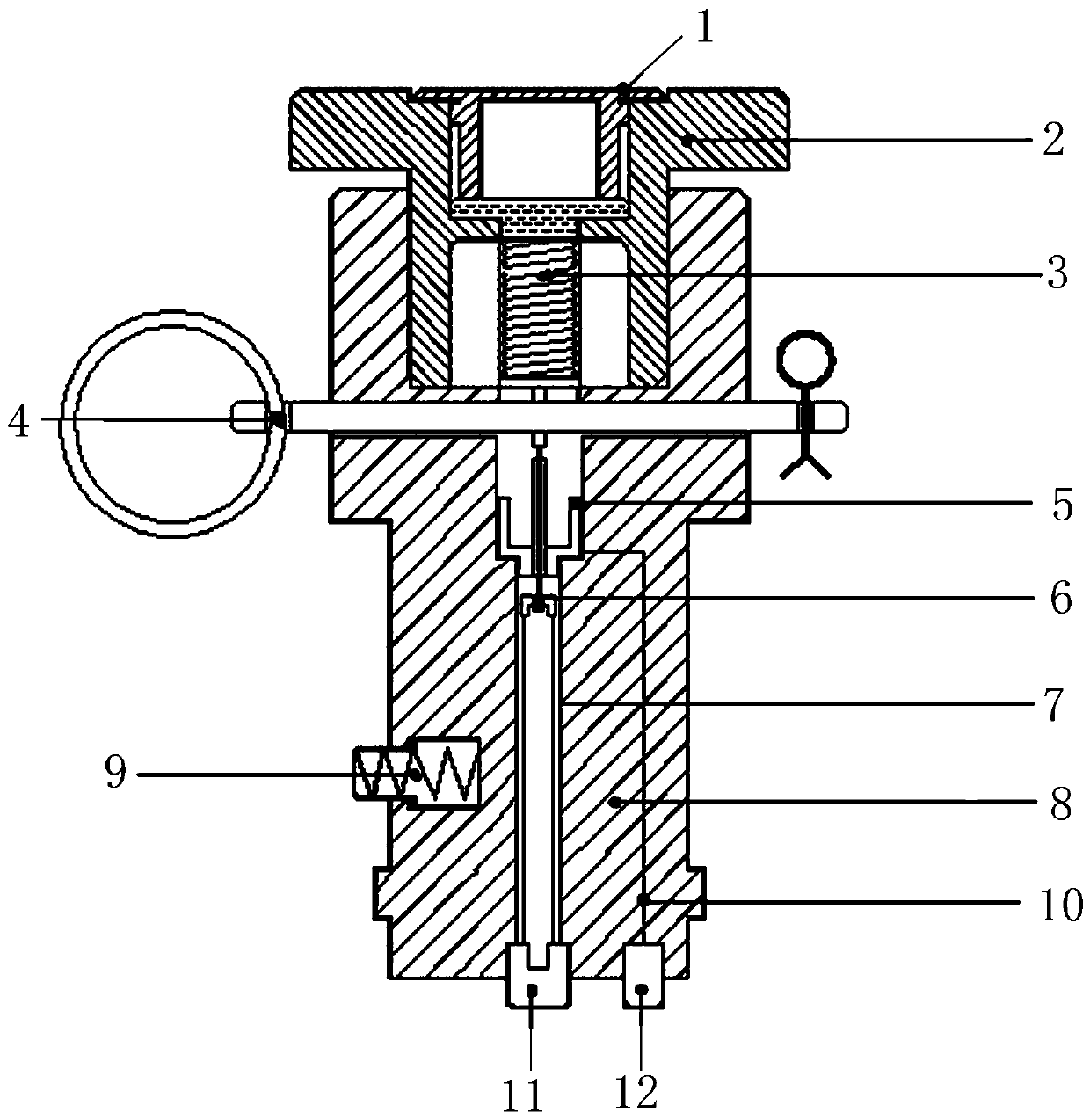

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] A modular and controllable delay trigger device, comprising a spring top cover 1, a spring screw cover 2, a spring assembly 3, a safety pin 4, a stepped negative metal sleeve 5, an insulating drawing wire 6, a fusible alloy 7, and an insulating housing 8 , Conductive metal sheet 10, positive electrode contact 11, negative electrode contact 12.

[0026] Such as figure 2 As shown, the central coaxial line in the insulating housing 1 is provided with continuous stepped cavities to form three cavities with different diameters. The spring screw cover 2, the spring assembly 3, the safety pin 4, the stepped negative metal sleeve 5, the insulating drawing wire 6, the fusible alloy 7, and the positive contact 11 are connected in sequence.

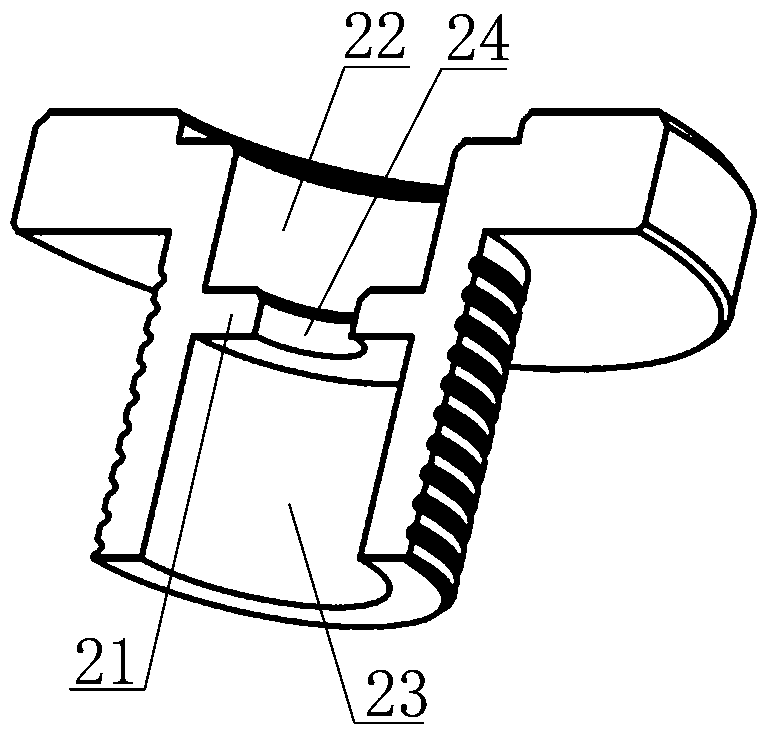

[0027] Such as image 3 As shown, the spring screw cap 2 is hollow and the middle is separated into an open u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com