Yellow tea and preparation method thereof

A technology of yellow tea and Jinxuan tea tree, applied in the field of yellow tea and its preparation, can solve the problems of lower product quality, dull product aroma, long processing time, etc., achieve sweet and long aroma, avoid dull taste and turbidity of tea soup Effects of deterioration and shortening of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

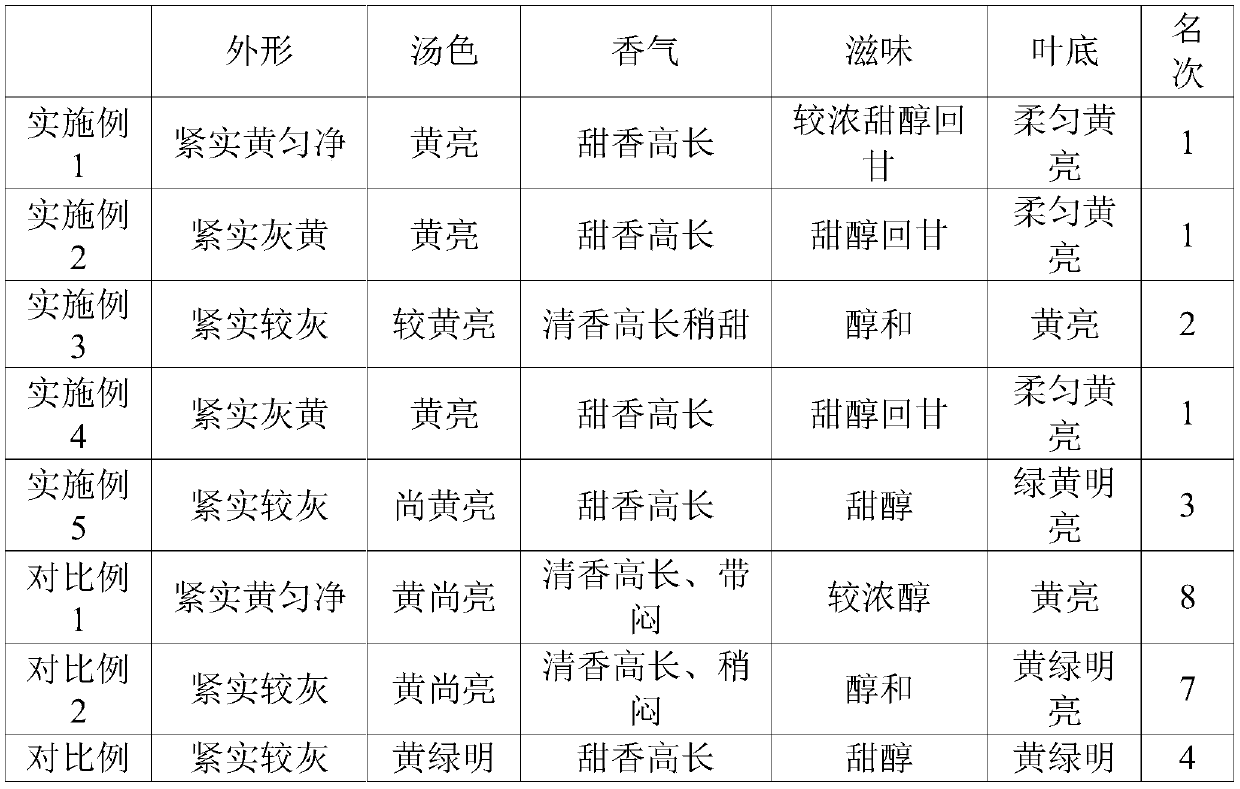

Examples

preparation example Construction

[0027] The present embodiment provides a kind of preparation method of yellow tea, comprises the following steps:

[0028] (1) Spreading: spread the fresh leaves, and spread the leaves;

[0029] (2) Finishing: the leaves are spread out at 220-300°C for (8-15) minutes to obtain green leaves;

[0030] (3) kneading: kneading the green leaves to obtain kneading leaves;

[0031] (4) initial drying or initial frying: initial drying or initial frying of the kneaded leaves until the moisture content is 10-20%, to obtain initial drying leaves or initial frying leaves;

[0032] (5) Titian: seal the first-baked leaves or first-fried leaves at 75-100° C. to obtain Titian leaves;

[0033] (6) Re-drying or re-frying: re-drying or re-frying the Titian leaves until the water content is below 6%.

[0034] Preferably, the time for sealing and improving fragrance in step (5) is (3-6) hours. Further preferably, the time for sealing and enhancing fragrance in step (5) is (3.5-4.5) hours.

[0...

Embodiment 1

[0048] (1) Spreading: Take 15 kg of fresh leaves of Yinghong No. 9 with one bud and two leaves, spread them for 12 hours, and spread the leaves;

[0049] (2) Finishing: Throw 15 kilograms of said spreading leaves in the drum-type gas fixing machine, and at 260° C., finish for 4 minutes at a speed of 20 rpm (for the tea leaves obtained, see figure 2 ), then reduce the speed to 8 rev / min and continue to finish for 6 minutes, the leaves are released, and the leaves are cooled with cold wind (for the tea leaves obtained, see figure 1 );

[0050] (3) Kneading: Put the cooled green leaves into the 40-type kneading machine, first knead for 5 minutes in the air, then lightly press for 7 minutes, knead for 3 minutes in the air, 7 minutes in the medium pressure, and knead for 3 minutes in the air, and the lower leaves will be kneaded; Gained kneading leaves are deblocked with a deblocker;

[0051] (4) initial drying: the kneading leaves after deblocking are initially dried with a thi...

Embodiment 2

[0055] (1) Spreading: Take 15 kg of fresh leaves of Jinxuan with one bud and two leaves, and spread them for 12 hours, until the leaves are spread;

[0056] (2) Finishing: Throw 15 kg of the spread leaves in the drum-type gas fixing machine, at 260°C, finish with a speed of 20 rpm for 4 minutes, then reduce the speed to 8 rpm and continue for 6 minutes , out of the leaves, cool and kill the green leaves with cold wind;

[0057] (3) Kneading: Put the cooled green leaves into the 40-type kneading machine, first knead for 5 minutes in the air, then lightly press for 7 minutes, knead for 3 minutes in the air, 7 minutes in the medium pressure, and knead for 3 minutes in the air, and the lower leaves will be kneaded; Gained kneading leaves are deblocked with a deblocker;

[0058] (4) Initial frying: Stir-fry the unblocked rolled leaves with a drum-type gas greening machine at 260°C at a speed of 20 rpm until there is no green stem, and the hand feels thorny (the water content is 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com