Device for transporting sheets of printing material

A technology for printing materials and sheets, applied in the field of equipment conveyed by printing stations, can solve the problems of printing image interference, small support width, insufficient accuracy, etc., and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

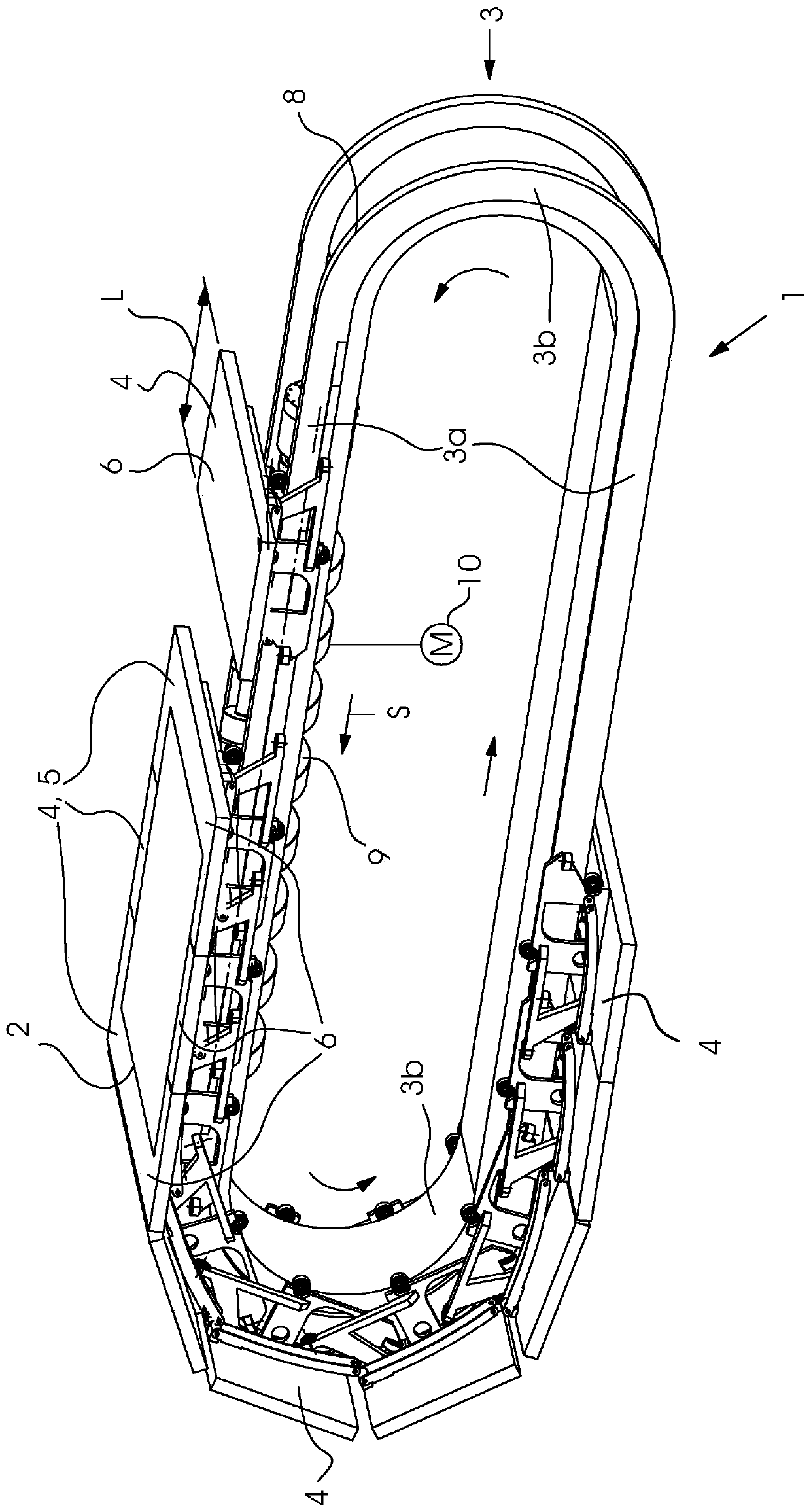

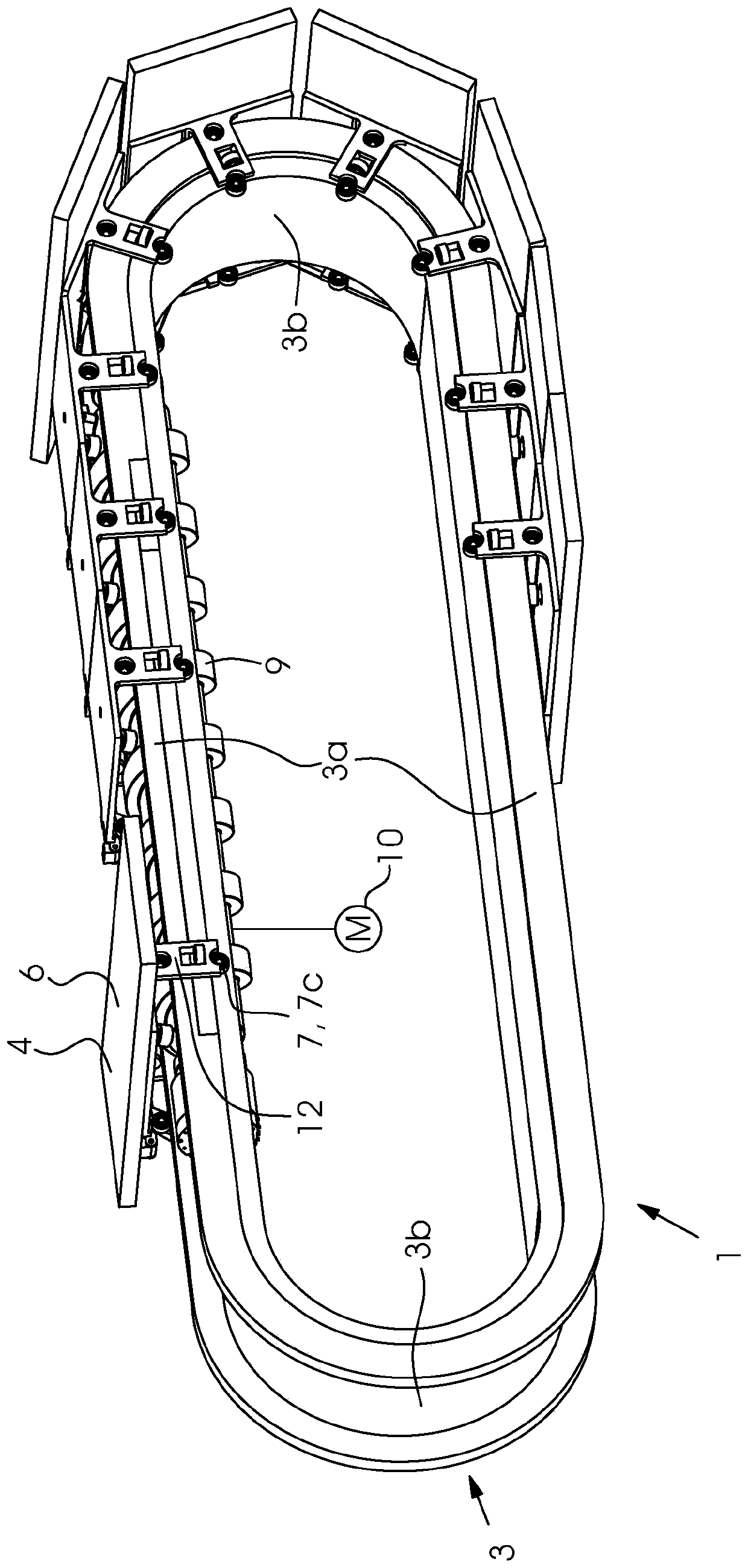

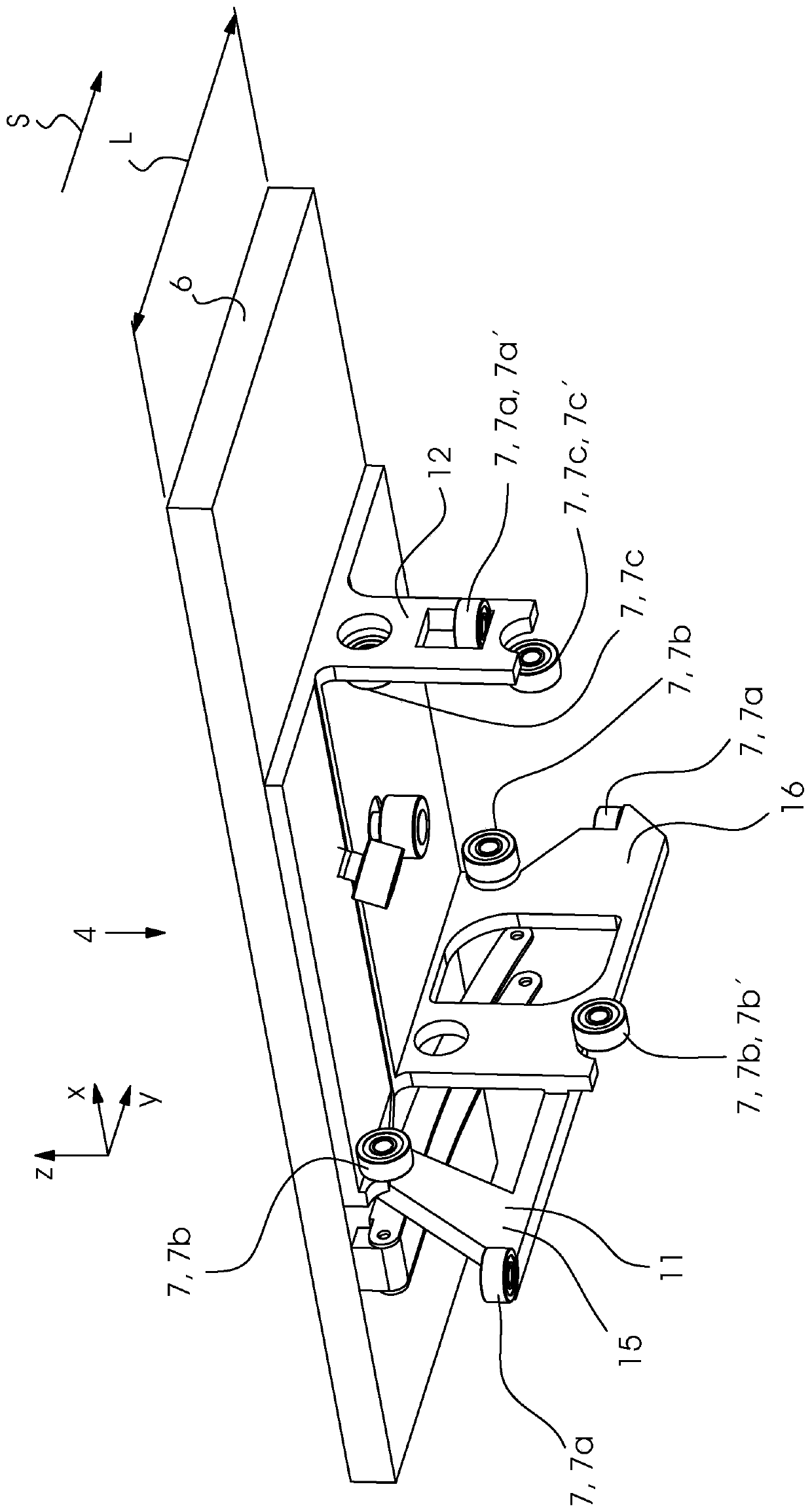

[0033] figure 1 A front view is shown of a preferred embodiment of a device 1 according to the invention for transporting sheets 2 of printing material such as paper, cardboard or plastic film. The device 1 may be part of a (not shown) printing press, in particular with a plurality of ink printing heads 18 (see Figure 5 ) part of an industrial ink printing machine.

[0034] The device 1 comprises a conveying path 3 , in particular a closed (“endless loop”) conveying path, for example in the form of an ellipse-like combination of two semicircles and a rectangle.

[0035] The conveying path 3 preferably comprises at least one straight conveying section 3a and at least one curved (preferably semicircular) conveying section 3b, for example forming a closed conveying path in the sequence 3a, 3b, 3a, 3b.

[0036] At least one sheet transport section 4 , but preferably (as shown) a plurality of sheet transport sections 4 moves along the transport path 3 . In this case, a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com