Trestle type lower-opening full-cross-section synchronous construction equipment and construction method thereof

A simultaneous construction and full-section technology, which is applied to mining equipment, underground chambers, shaft equipment, etc., can solve the problems of extended construction period of guide pillars, high costs of various types, and low construction efficiency, so as to reduce the investment in personnel and auxiliary equipment , save cost and construction space, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

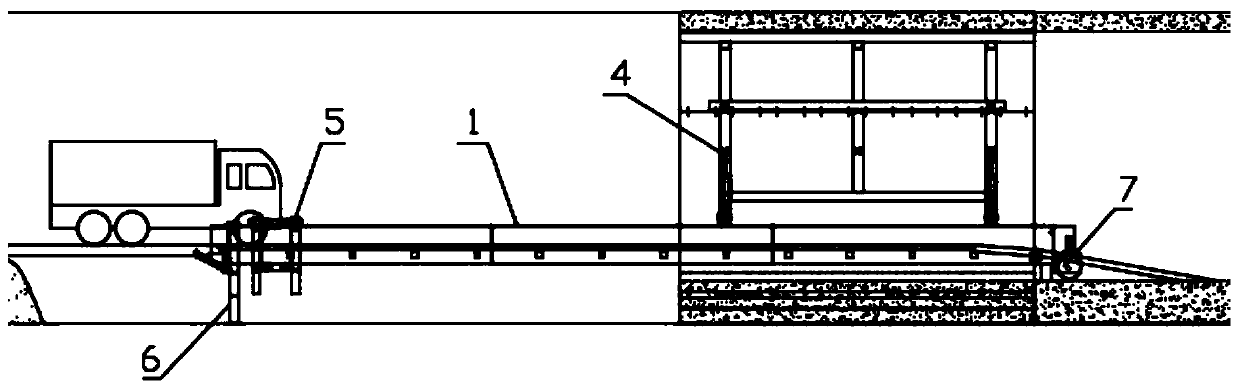

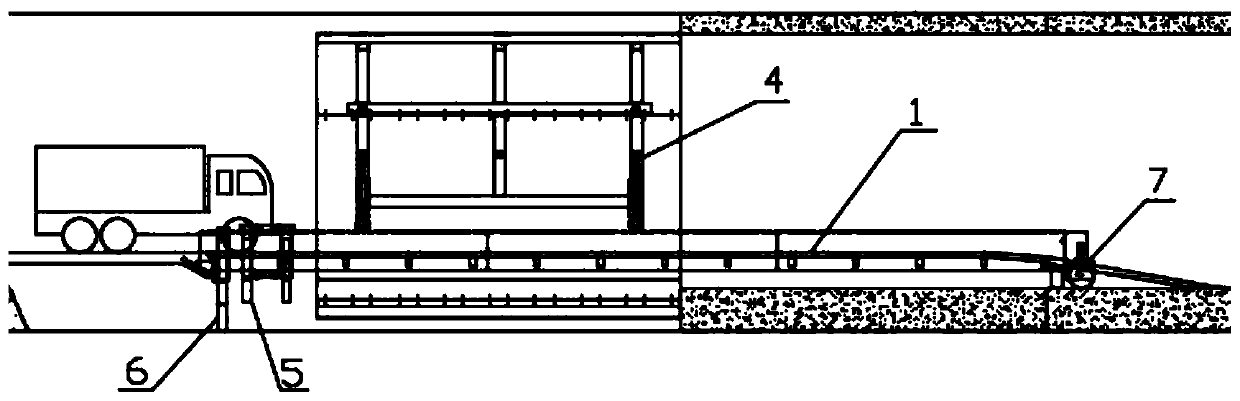

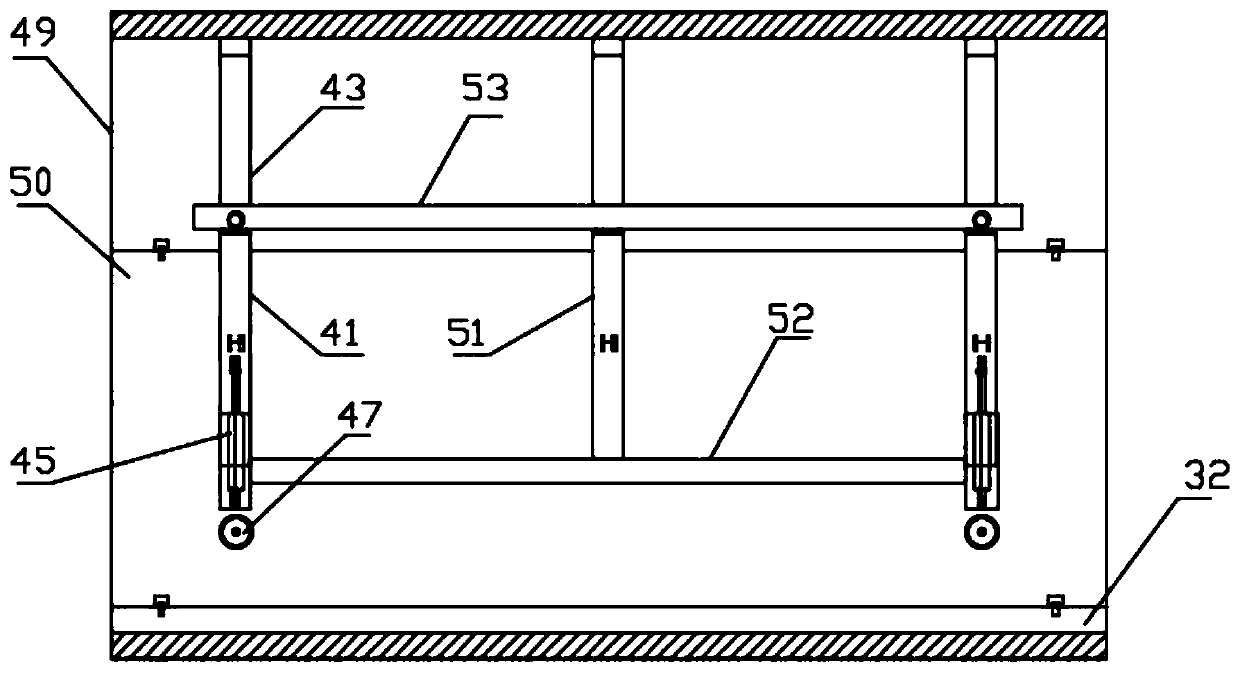

[0029] Such as Figure 1-Figure 9 As shown, a specific embodiment: a trestle-type lower opening full-section synchronous construction equipment, a trestle-type lower opening full-section synchronous construction equipment, including a self-propelled trestle 1, the self-propelled trestle 1 is provided with an overall structure It is an inverted U-shaped full-section formwork trolley 4; a top form 49 for pouring the top surface of the tunnel is arranged above the full-section formwork trolley 4; the two ends of the top form 49 are hinged side forms 50; the side forms 50 The side cylinder 48 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com