Automatic production device for brake disc housing

A technology for production devices and brake discs, which is applied to feed devices, positioning devices, storage devices, etc., can solve the problems of large equipment occupation, difficult turnover, unstable products, etc., and achieves small equipment occupation space, convenient storage and transportation, The effect of convenient automatic collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

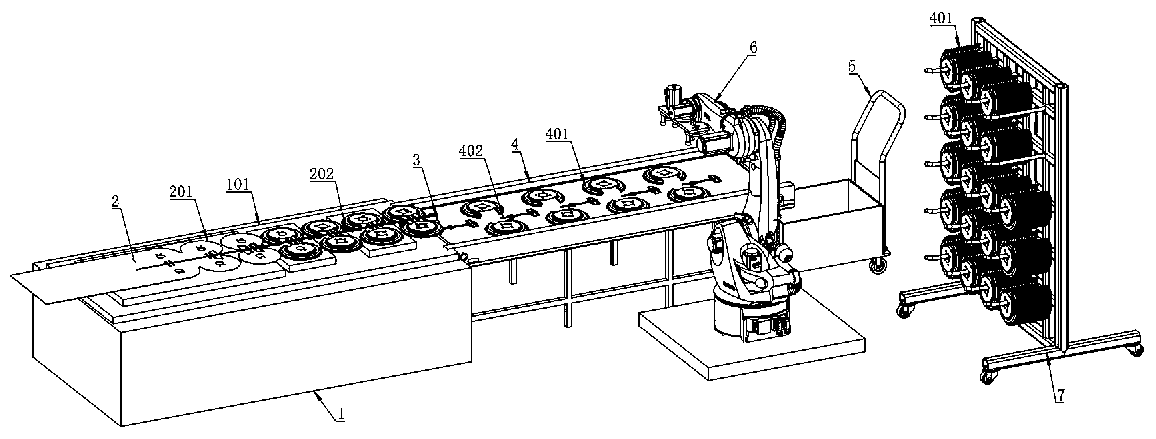

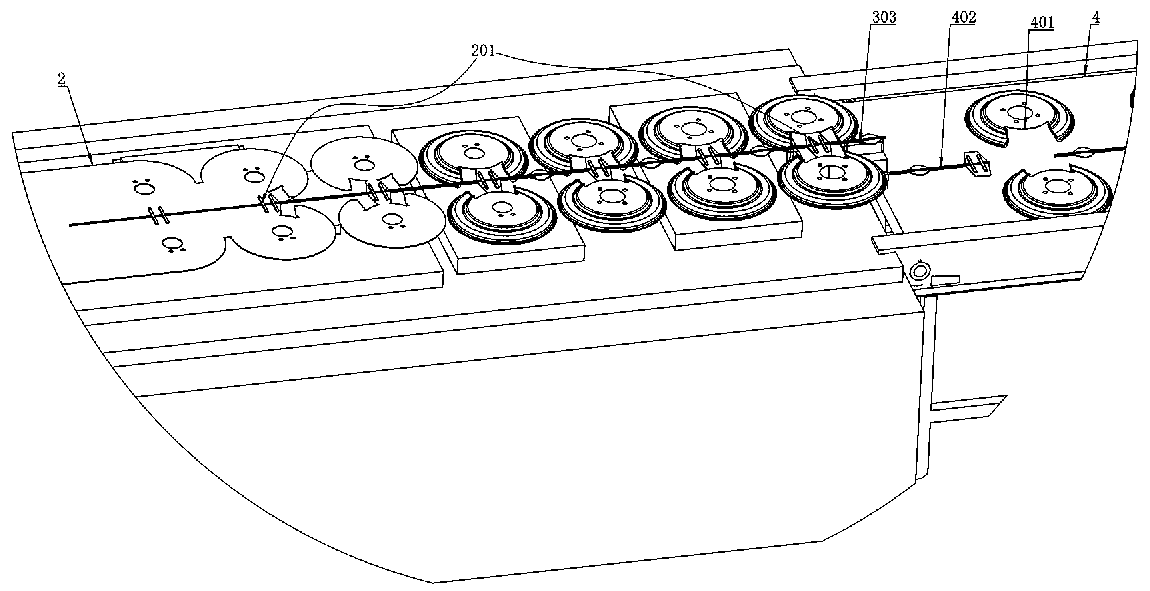

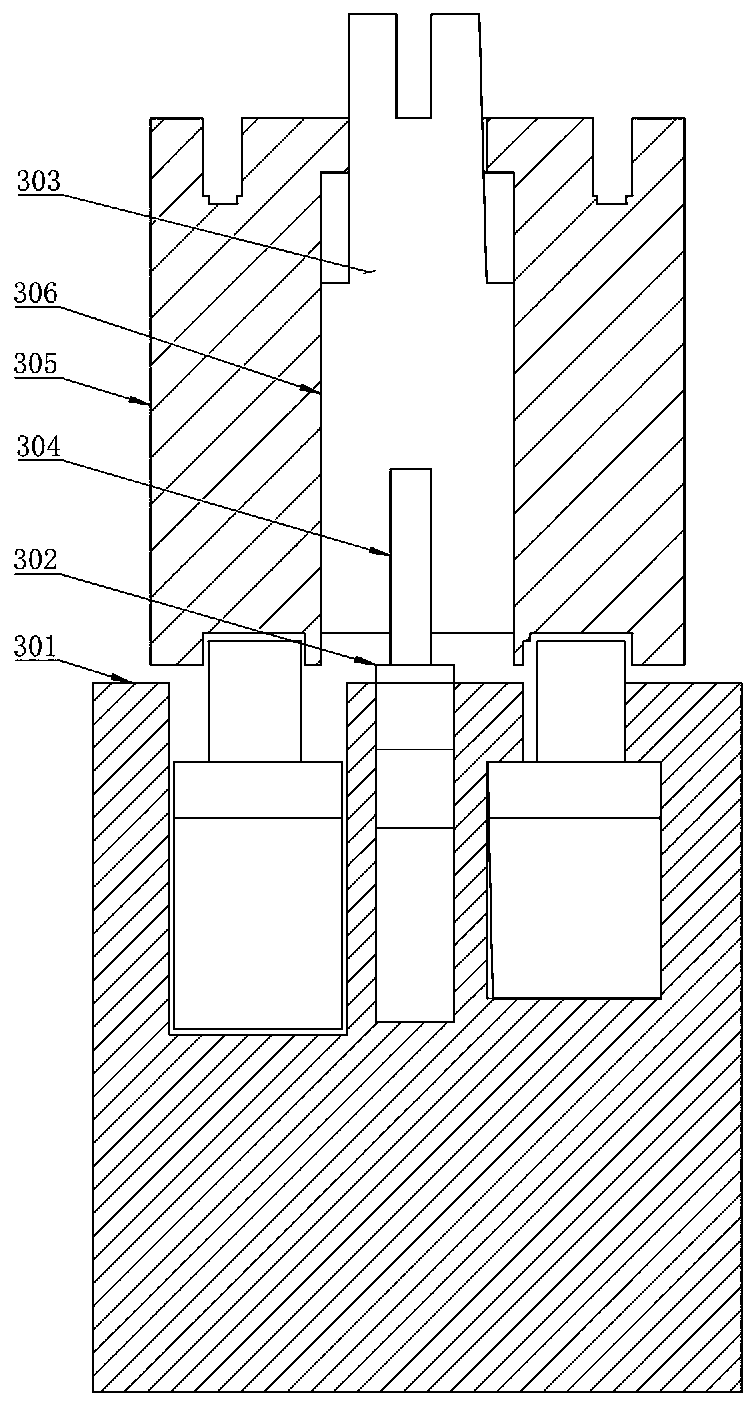

[0030] Specific implementation mode one: combine Figure 1-6 As shown, the brake disc cover automatic production device is characterized in that it includes a punching machine 1, a steel plate 2, a double floating material device 3, a conveyor belt 4, a waste trolley 5, a multi-axis joint handling robot 6 and a storage rack 7; The punching machine 1 is provided with a punching platform 101; the steel plate 2 is set on the punching platform 101; the right side of the steel plate 2 is provided with a material belt 201 on the punching platform 101; the double floating material device 3 is set on the punching platform 101 above the right end; the conveyor belt 4 is set on the right side of the bottom of the double floating material device 3; the waste trolley 5 is set under the right end of the conveyor belt 4; the multi-axis joint handling robot 6 is set on the side of the conveyor belt 4 The storage rack 7 is set on the right side of the multi-axis joint handling robot 6; the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com