Production method of positioning connecting bracket

A production method and a technology for connecting brackets are applied in the production field of positioning and connecting brackets, which can solve the problems of difficult to achieve bending accuracy, cracking at the bending place, and large bending springback, and achieve high accuracy, stable bending angle, and prevent The effect of bending and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The relevant details of the present invention will be further described below in conjunction with the accompanying drawings.

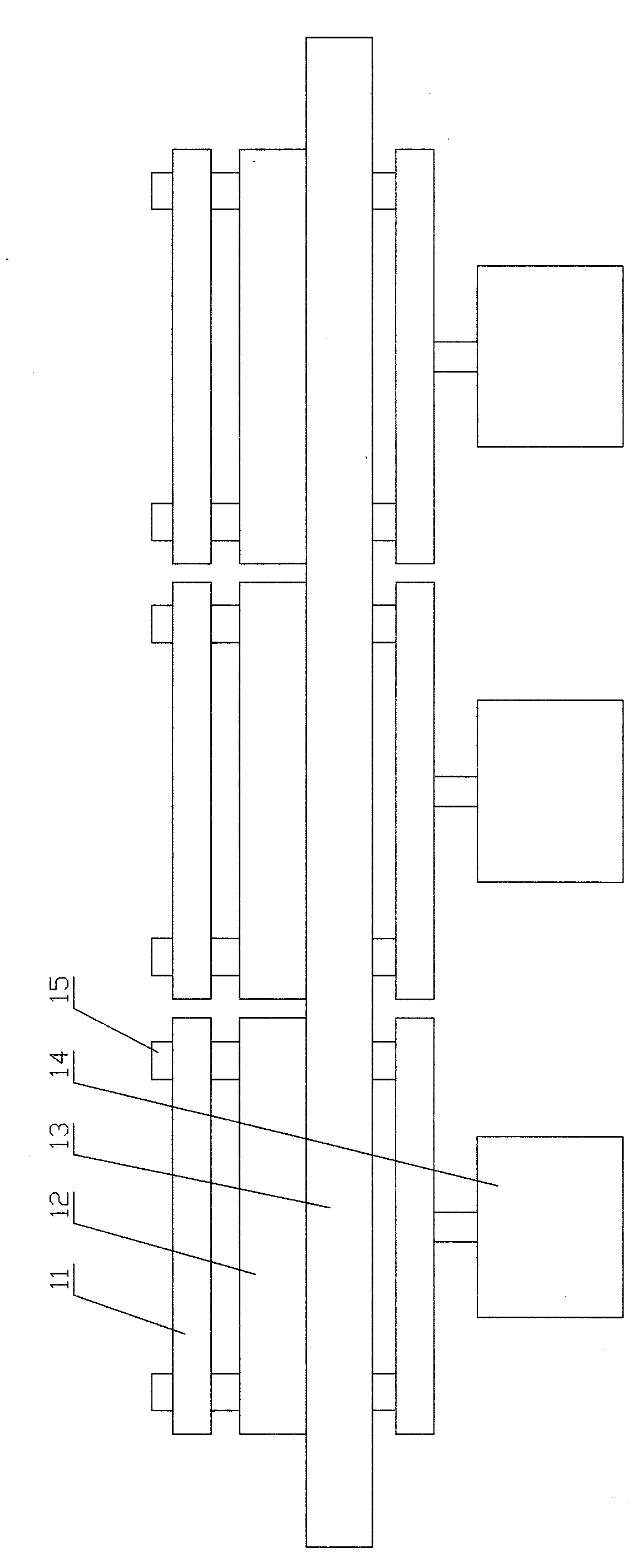

[0016] The production method of the positioning connection bracket includes the following steps:

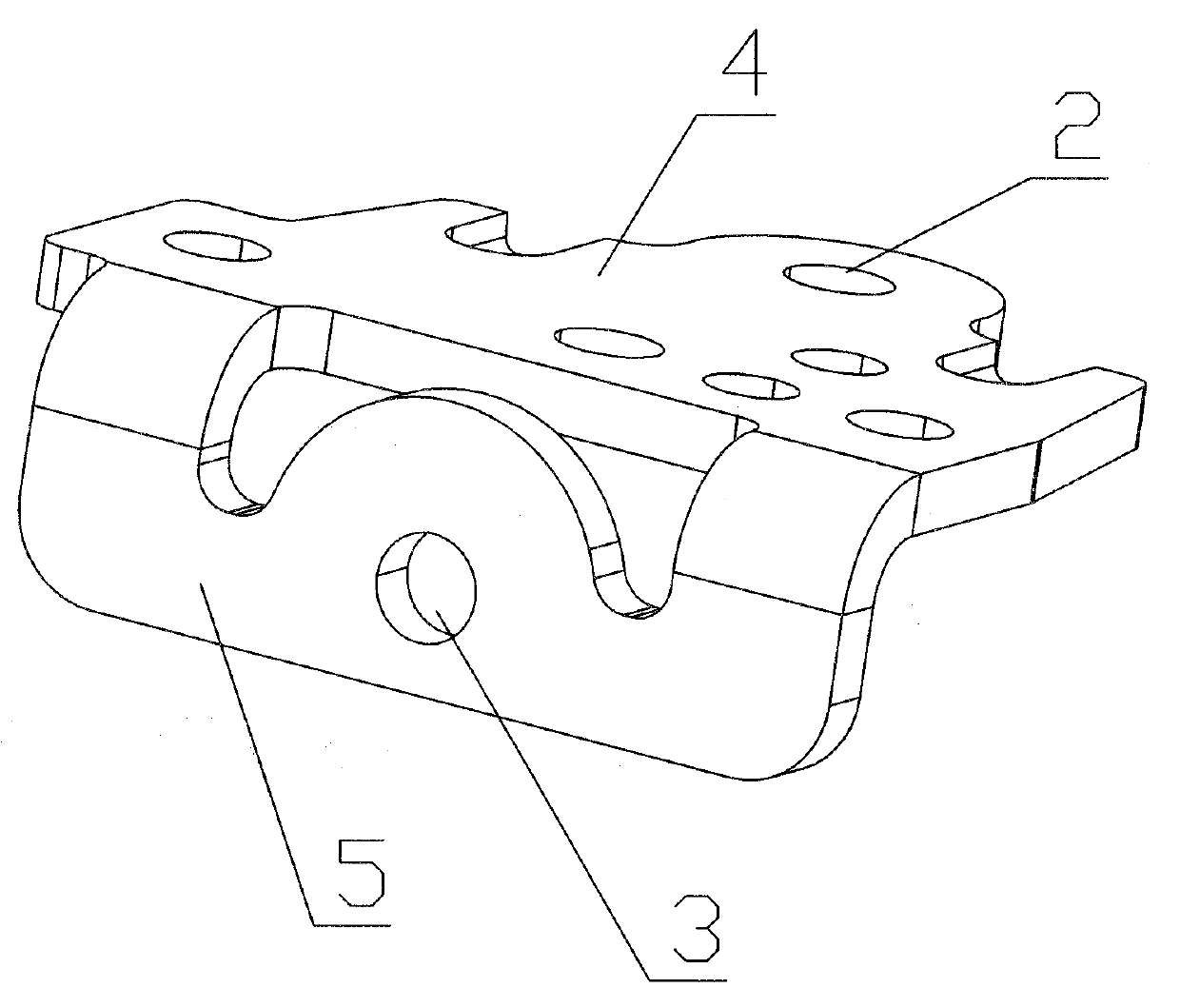

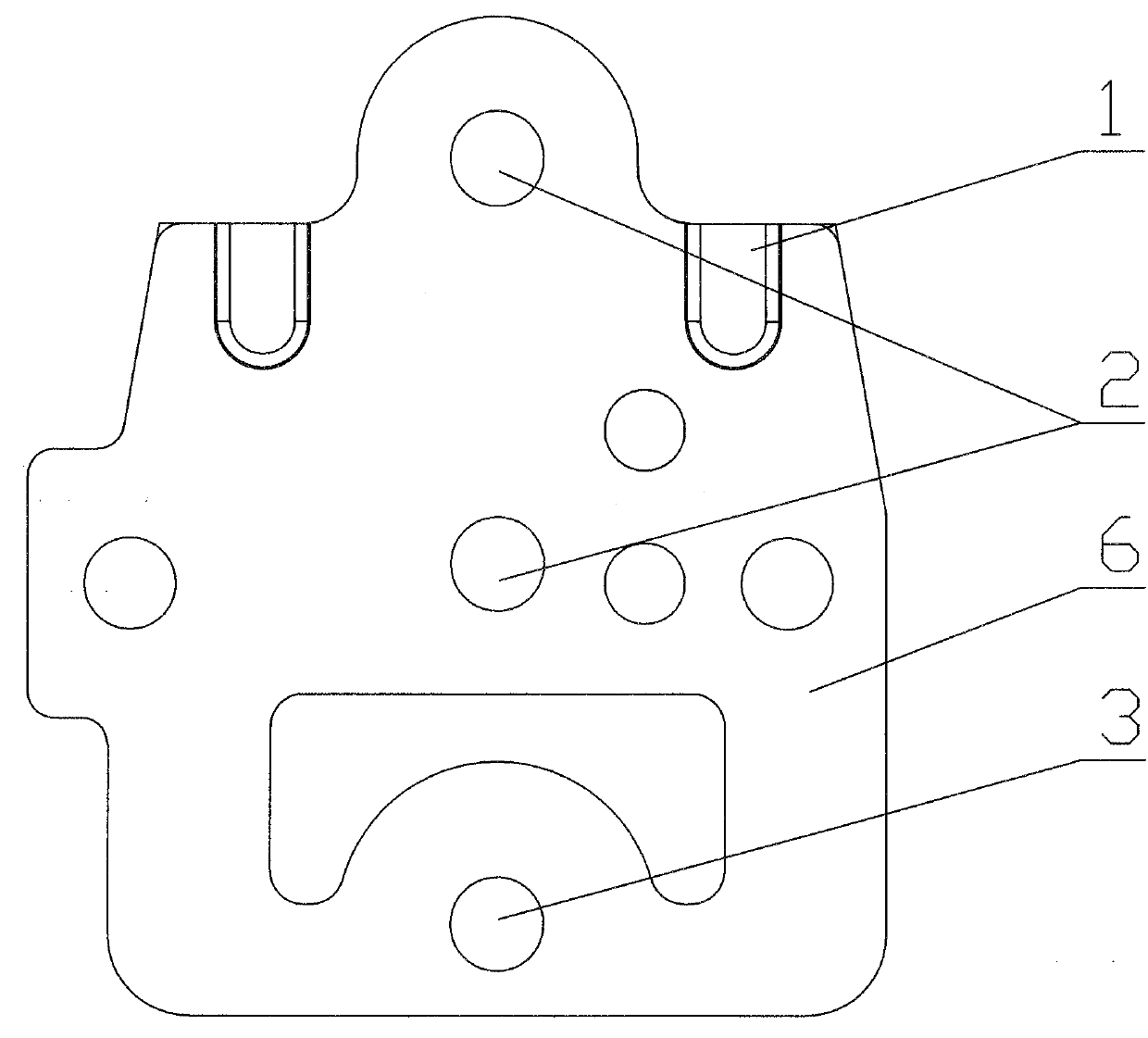

[0017] 1) The bracket body 6 is formed by continuous fine blanking and deburred. The bracket body 6 has three installation holes and two bosses 1. The bosses 1 are arranged at both ends of the bracket body 6. Three The installation holes are two bearing installation holes 2 and one connecting rod installation hole 3 respectively. The center points of the three installation holes are on the same straight line, and there are processing surplus materials in the three installation holes, and the surplus materials are reserved for 0.5mm. The remaining material is processed by subsequent milling machines.

[0018] 2) The bracket body 6 is bent so that the side 5 with the connecting rod mounting hole is perpendicular to the bottom surface 4 with the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com