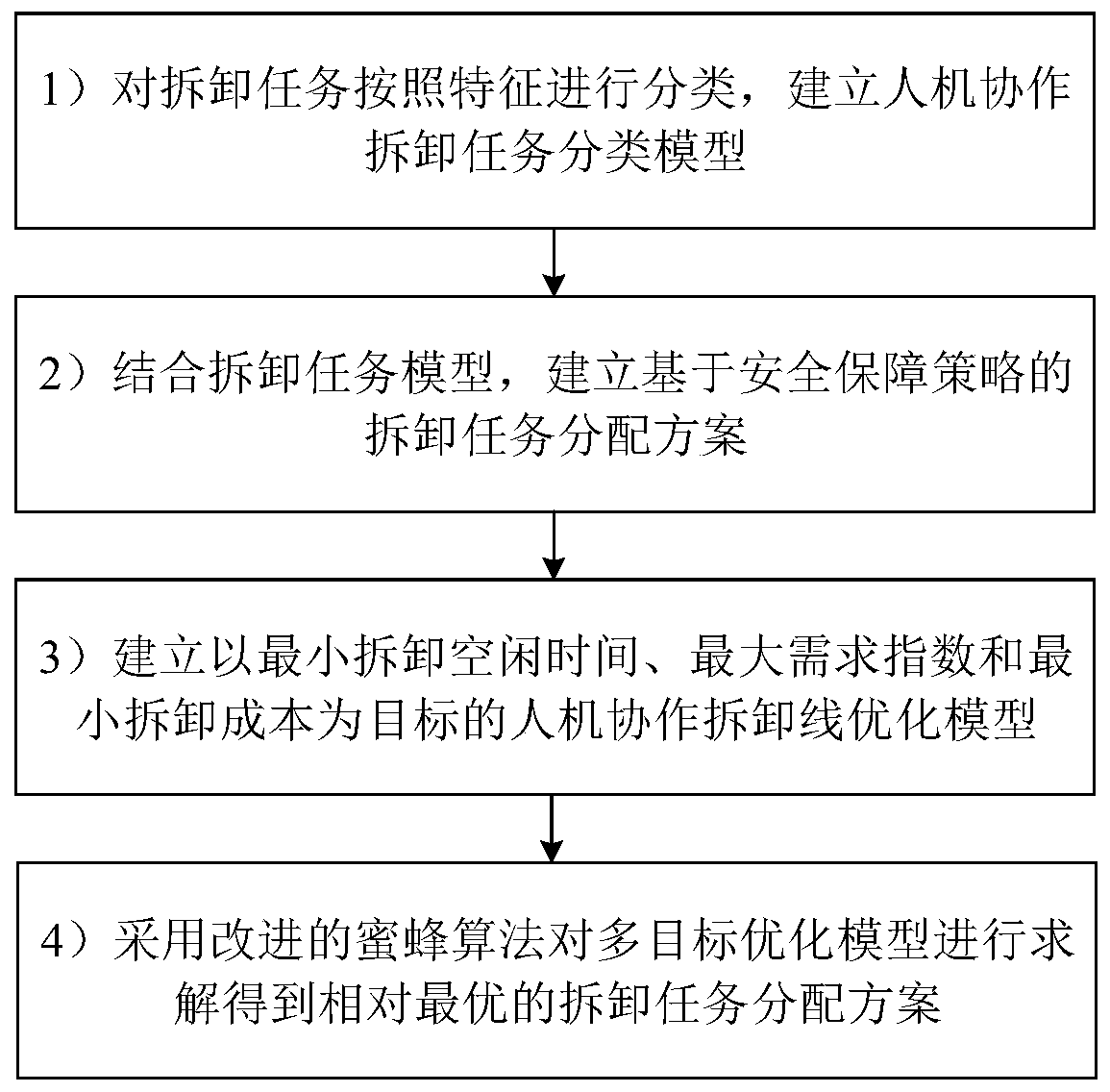

Man-machine cooperation disassembly line balance optimization method based on safety guarantee strategy

A technology of man-machine cooperation and safety assurance, applied in the direction of manipulators, assembly machines, metal processing, etc., can solve the problems of disassembly lines that have not been considered, cannot be aligned, etc., and achieve the effect of low disassembly cost, short disassembly time, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

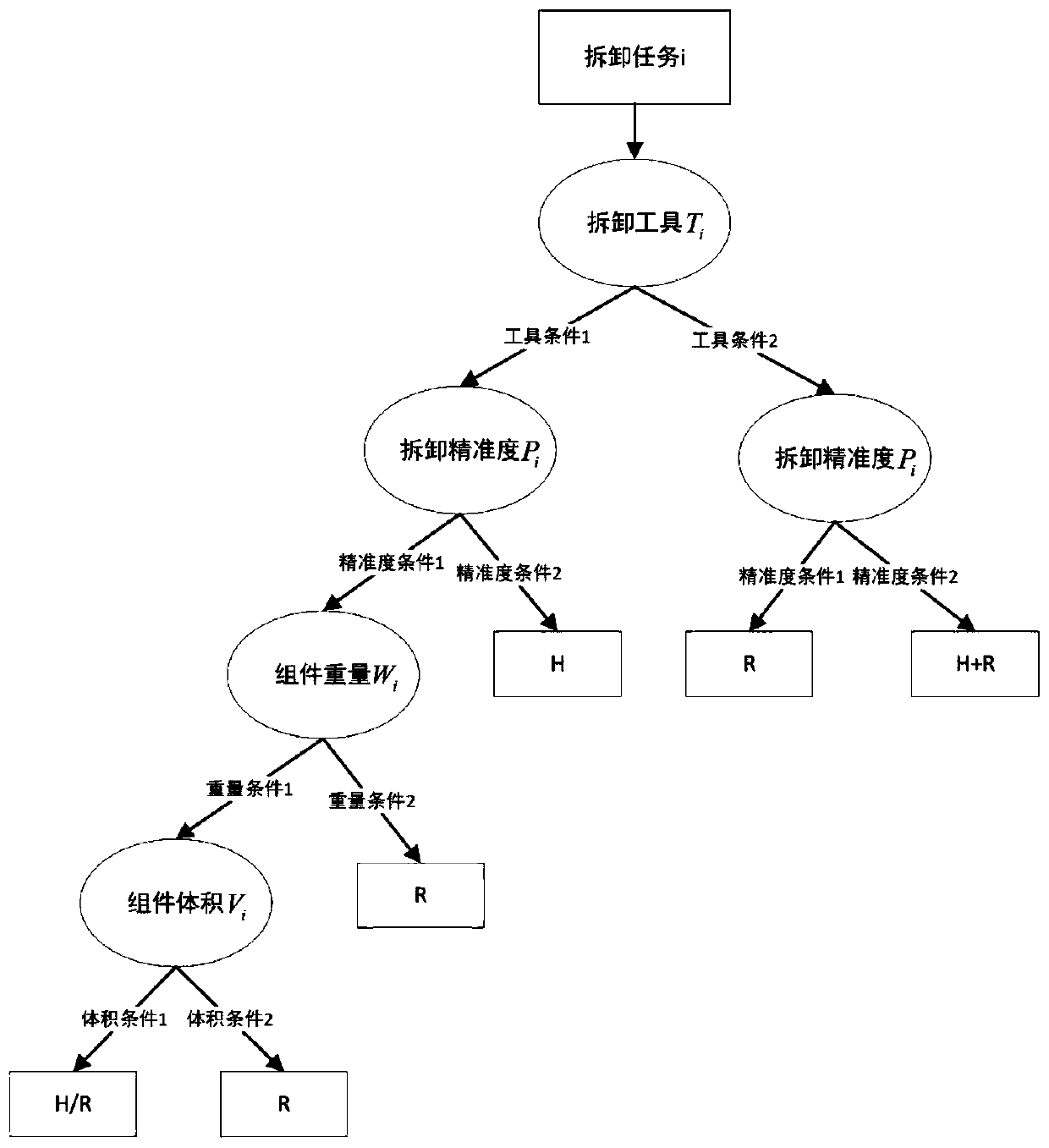

[0112] The disassembly process of a certain type of coupling is analyzed and explained. The example contains 37 disassembly tasks. For these disassembly tasks, the disassembly tasks are classified according to the scheme shown in step 1), and the classification decision tree is as follows figure 2 shown.

[0113] figure 2 The tool condition 1 in means that the tools used can be disassembled manually or by robots. Tool condition 2 means that disassembly can only be done using robotic tools. Accuracy condition 1 indicates that the accuracy required for the disassembly task is relatively low, and accuracy condition 2 indicates that the accuracy required for the disassembly task is relatively high, and an operator is required to disassemble. Weight condition 1 means that the weight of the components involved in the disassembly task is small, and both humans and robots can be selected. Weight condition 2 indicates that the weight of the component is relatively large, requirin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com