A stone grinder with adjustable grinding area for bridge construction

A bridge construction and adjustable technology, which is applied to machine tools suitable for grinding workpiece planes, parts of machine tools, grinding heads, etc., can solve problems such as single function, roughness, and inability to meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

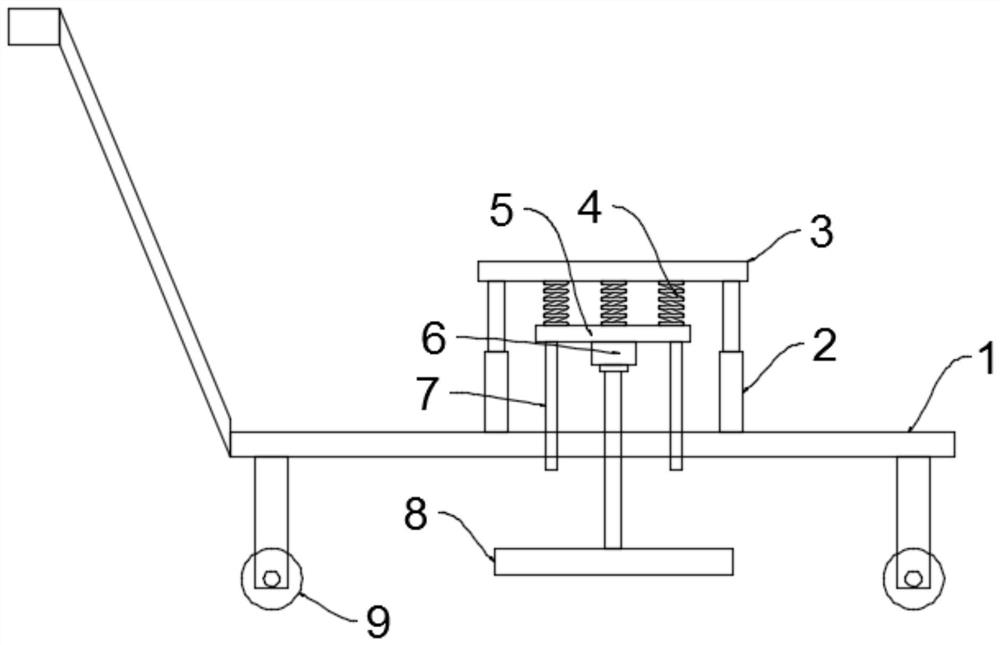

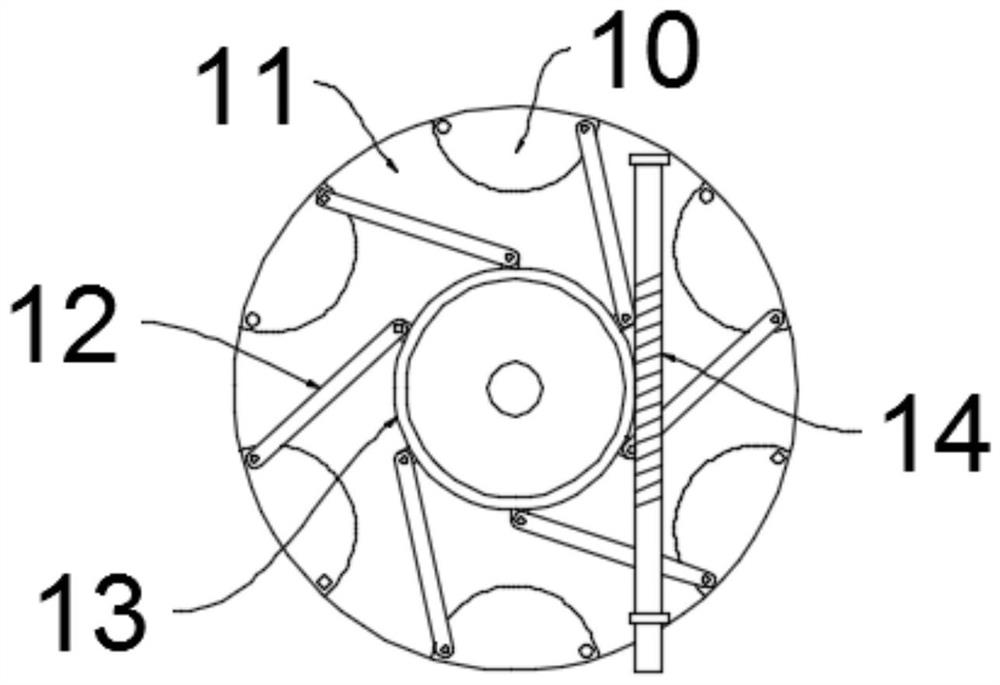

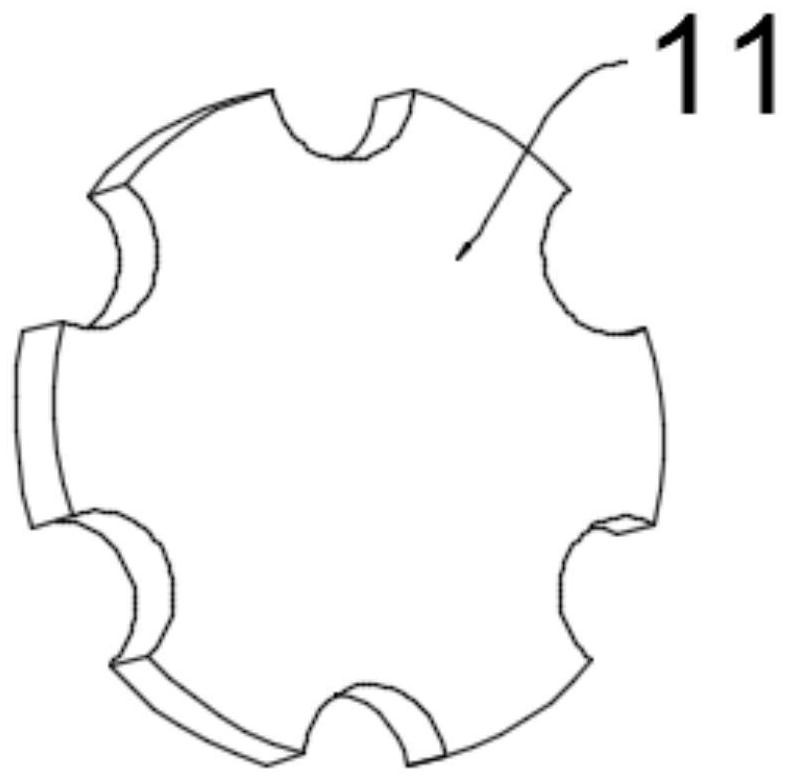

[0025] see Figure 1~3 , in an embodiment of the present invention, a grinding stone machine with adjustable grinding area for bridge construction, comprising a frame 1 and a grinding unit, the bottom of the frame 1 is evenly and symmetrically fixed with support legs, and the bottom end of the support legs is equipped with rollers 9 , the roller 9 is a self-locking roller, the grinding unit includes a grinding assembly and a lifting mechanism for driving the grinding assembly up and down, and the grinding assembly includes a grinding shaft, a first motor 6 for driving the grinding shaft to rotate and a fixed The grinding body 8 installed on the bottom end of the grinding shaft, the lifting mechanism includes the first electric push rod 2, the first mounting plate 3, the second mounting plate 5 and the compression spring 4, and the grinding assembly is installed under the second mounting plate 5 On the surface, the second mounting plate 5 is located above the frame 1, and the f...

Embodiment 2

[0028] see Figure 4 The difference between the embodiment of the present invention and embodiment 1 is that further, due to the dust generated during grinding, which affects the environment and the health of the staff, a dust reduction unit is also included, and the dust reduction unit includes a water tank 15 and a nozzle 16. The water tank 15 is fixedly installed on the frame 1, the top of the water tank 15 is provided with a water inlet, the bottom of the water tank 15 is connected with a water outlet pipe, and a booster pump is installed on the water outlet pipe, and the bottom of the frame 1 is located on one side of the grinding body 8 and a nozzle is installed 16, the outlet pipe is connected with the shower head 16.

Embodiment 3

[0030] see Figure 5 The difference between the embodiment of the present invention and embodiment 2 is that, in order to ensure the cleanliness of the ground during grinding, avoiding debris affecting the grinding quality or even damaging the grinding body 8, a cleaning unit is also included, and the cleaning unit includes a second motor 18 , the second electric push rod 17, the third mounting plate 19 and the brush 20, the second motor 18 is fixedly installed on the third mounting plate 19, and the second mounting plate 19 is fixedly connected with the frame 1 The electric push rod 17, the output shaft of the second motor 18 is fixedly connected with the installation shaft through the coupling, the installation shaft runs through the frame 1 and is fixedly installed with the brush 20, and the third installation plate 19 is driven down by the second electric push rod 17 The brush 20 is in contact with the ground, and the second motor 18 drives the brush 20 to rotate, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com