Snap gauge structure in electric hydraulic tool and machining method and assembly-disassembly method thereof

A technology of hydraulic tools and clamping dies, which is applied in the field of clamping die structures, processing methods and loading and unloading, and can solve problems such as troublesome replacement of clamping die structures, many steps, and generation of metal debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

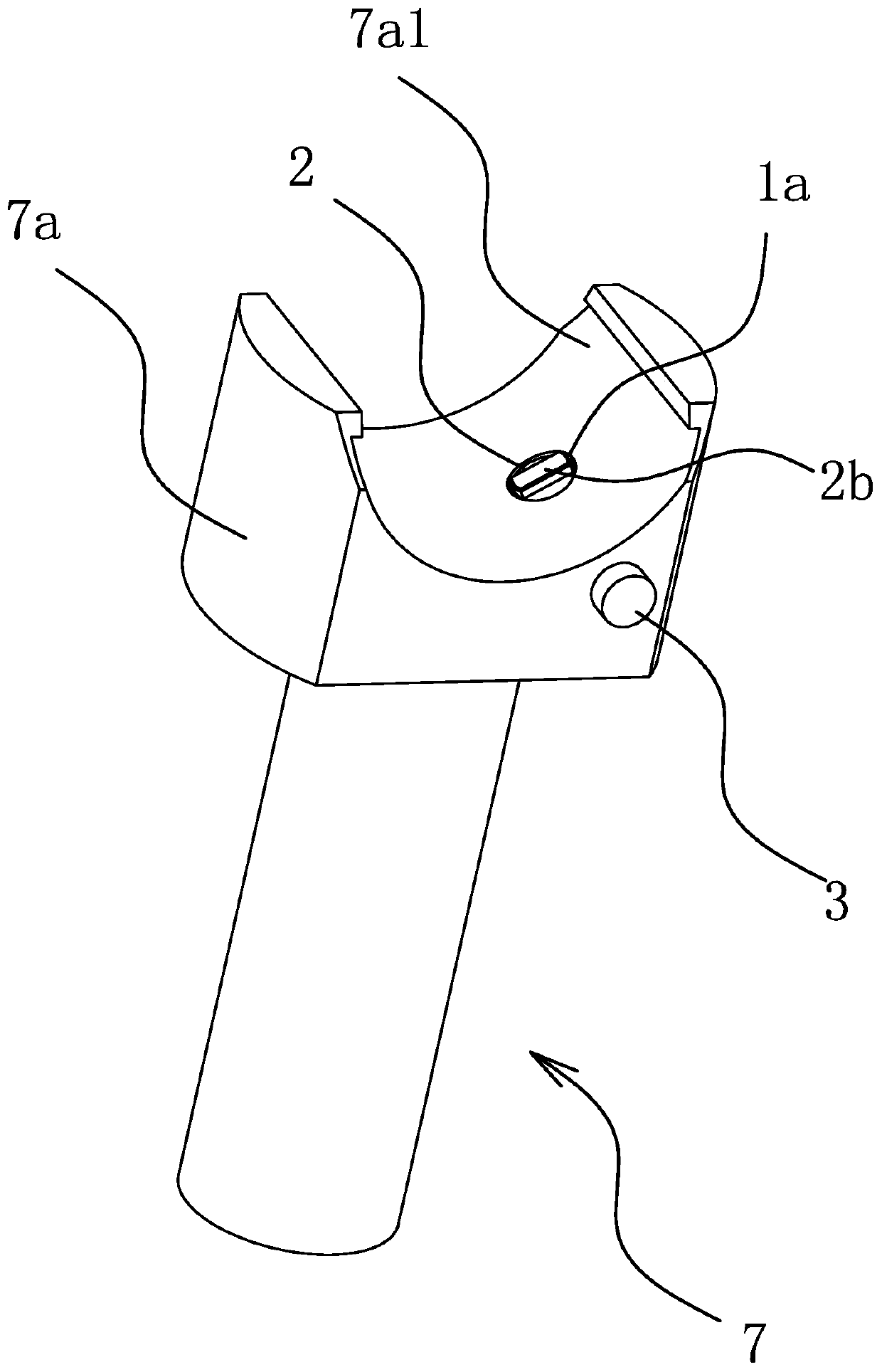

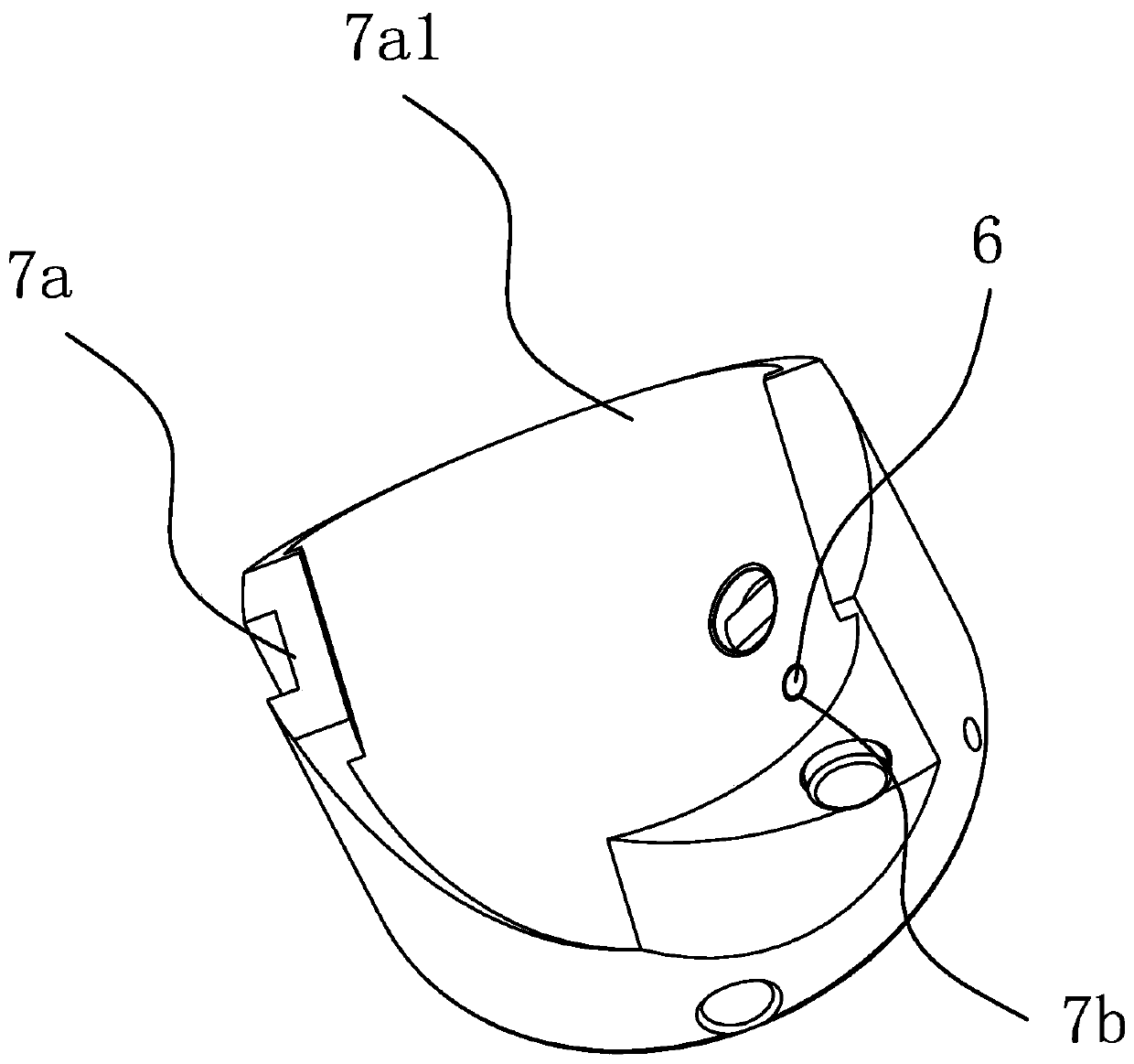

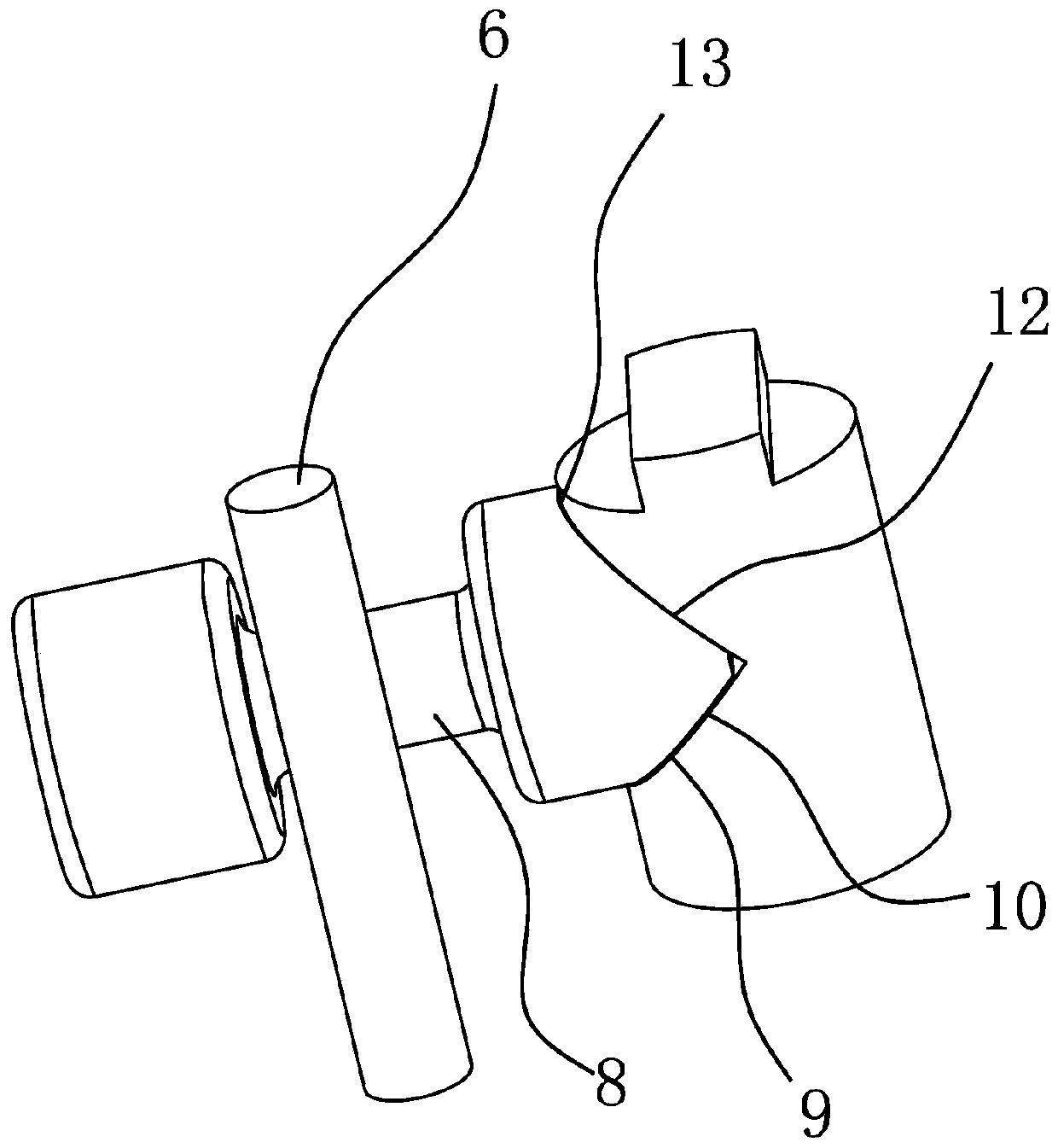

[0090] Such as Figure 1 to Figure 7 As shown, the clamping structure in the electric hydraulic tool includes a mounting hole 1, the mounting hole 1 has a first hole end 1a and a second hole end 1b, the clamping structure also includes a clamping head 2, and the clamping head 2 is located at the first The hole end 1a is provided with a through hole 2a on the card die head 2; it also includes a pressing shaft 3, which penetrates from the second hole end 1b, and the inner end of the pressing shaft 3 has an extension that can extend into or out of the through hole 2a. Into the section 3a, one end of the inserted section 3a has a stopper 3b that goes out of the perforation 2a, when the pressing shaft 3 is pressed inward, the clamping die head 2 enters the inner direction of the first hole end 1a and the clamping die head 2 has a tendency to reset ; The card die head 2 has a first state position 4 and a second state position 5. When the card die head 2 is in the first state positio...

Embodiment 2

[0103] Such as Figure 8 As shown, the difference between the present embodiment and the first embodiment is that the clamping die head 2 is in the shape of a rectangular block as a whole, the perforation 2a is a square hole and runs through the outer wall of the clamping die head 2, and the inner end of the pressing shaft 3 also has an extrusion with a slope. On the pressing surface 2, one end of the perforation 2a has an extrusion edge 2a2, and the extrusion surface 2 is an inclined plane. Extrusion surface 2 and extrusion surface 1 3c do not coexist, which is an independent technical feature in different technical solutions. In this technical solution, the rectangular block structure of the clamping die head 2 does not affect its up and down movement, and the extrusion surface is still used. The "point surface contact" or "edge surface contact" effect of the second and the extrusion edge 2a2 realizes the rapid downward pressure and rebound of the clamping die head 2. In pra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com