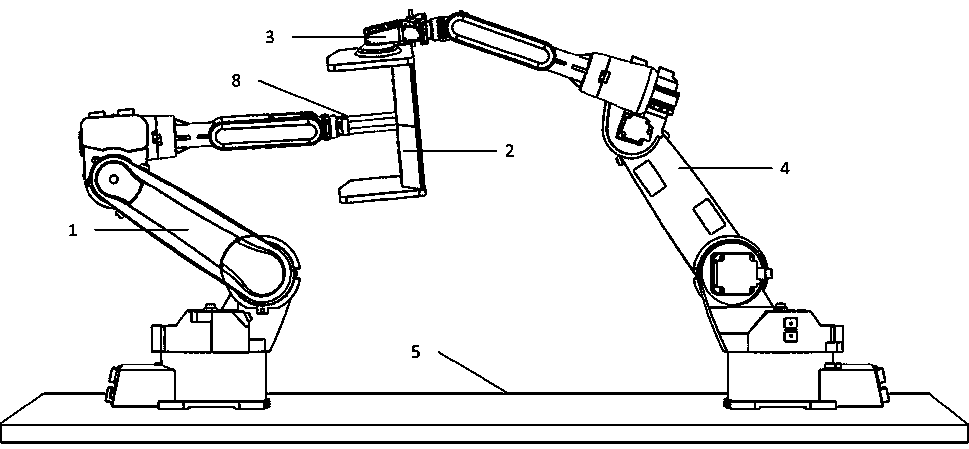

Dynamic model design method based on double mechanical arm cooperative grinding system

A dynamic model, dual-arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as insufficient consideration of dynamic knowledge such as joint motor torque, waste of time, and damage to the manipulator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

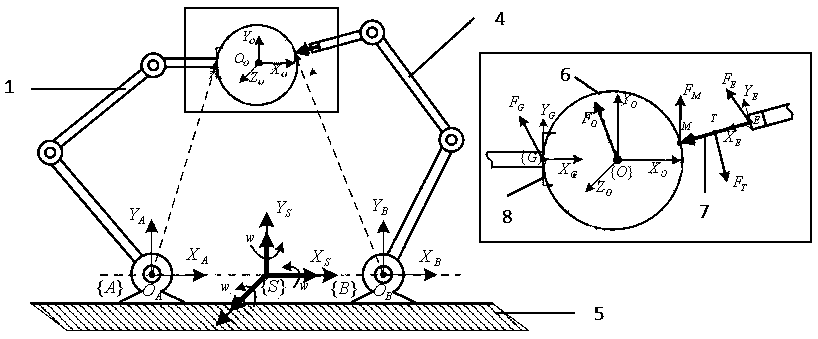

[0065] The dynamic model design method based on the dual-manipulator collaborative grinding system includes the following steps:

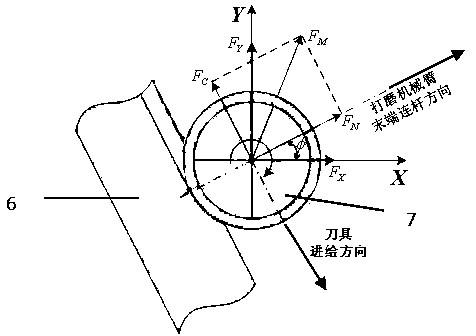

[0066] Step 1, constructing the Jacobian matrix of the dual robotic arm based on the grinding trajectory, at the kinematic level, based on the Jacobian matrix of the dual robotic arm, combined with the physical parameters of the grinding tool 7 and the clamped workpiece 6, the joints of the dual robotic arm Combined with the grinding trajectory, the Jacobian matrix from the grinding trajectory velocity to the joint velocity of each mechanical arm is constructed; the Jacobian matrix links the Cartesian space velocity of the grinding trajectory with the joint velocity of each dual robotic arm;

[0067] Step 2, constructing a simplified mechanical model of the grinding force of the grinding tool 7 and the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com