A manual tile cutter

A cutting machine and ceramic tile technology, applied in the field of hardware, can solve the problems of inability to adjust the cutting angle, difficult positioning, etc., and achieve the effect of improving the scope of application, flexible use, and simple use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

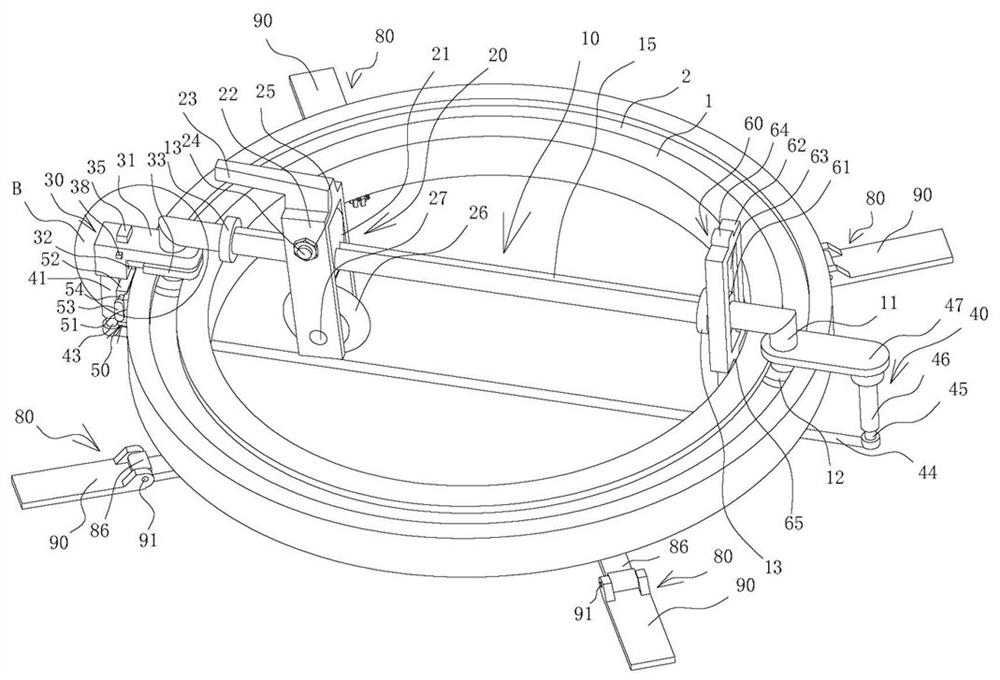

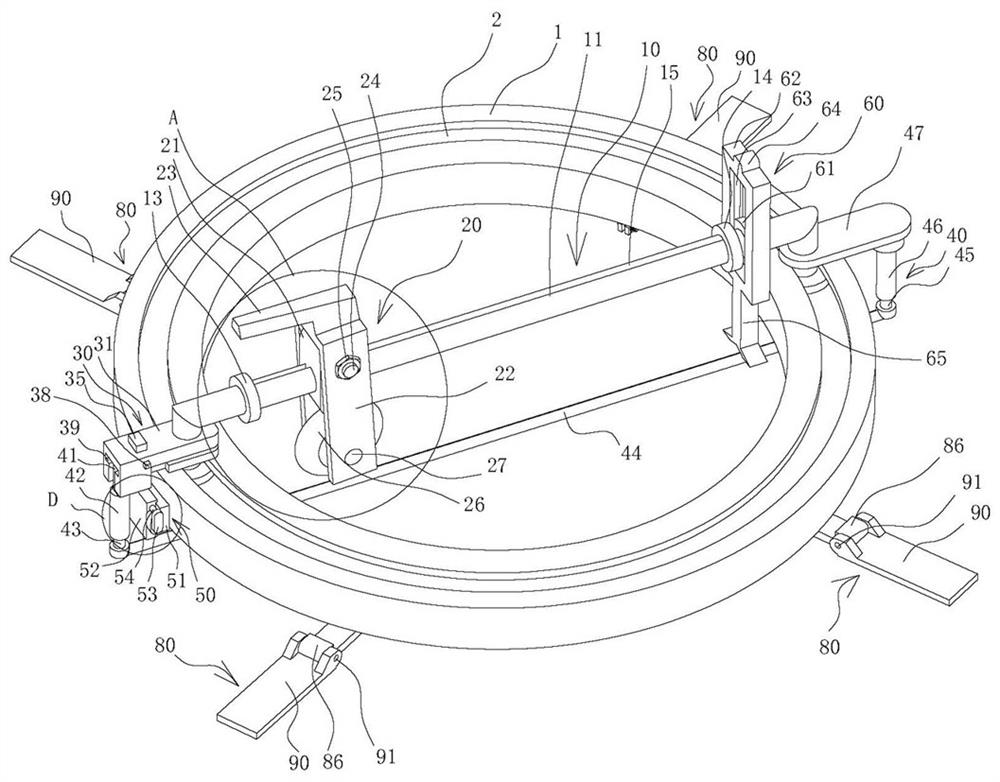

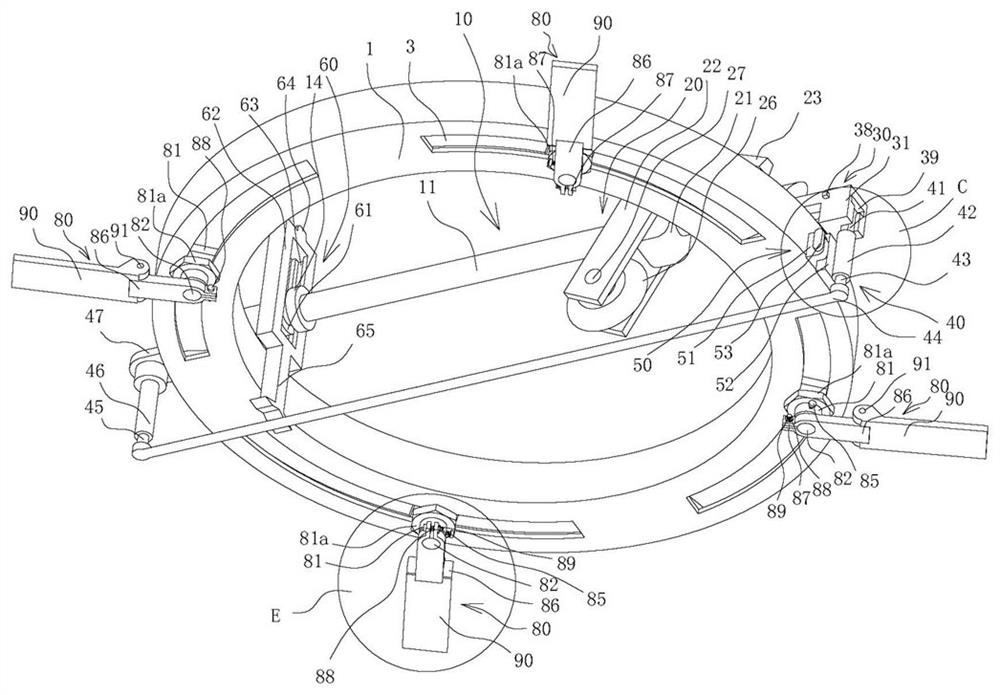

[0031] Such as figure 1 , figure 2 and image 3As shown, the manual tile cutting machine of the present invention includes a frame 1, the upper end of the frame 1 is provided with a first chute 2, the lower end of the frame 1 is provided with four evenly distributed second chute 3, and the first chute 2 is provided with There is a guiding mechanism 10, a cutting mechanism 20 is arranged in the middle of the guiding mechanism 10, a fixing mechanism 30 is arranged at the left end of the guiding mechanism 10, a pressing rod mechanism 60 is arranged at the right end of the guiding mechanism 10, and an auxiliary pressing rod mechanism is arranged at the left end of the fixing mechanism 30 60 impels the auxiliary mechanism 40 of tile fracture, the right end of the auxiliary mechanism 40 is connected with the right end of the guide mechanism 10, the left end of the frame 1 is provided with a vertical mechanism 50 to help the positioning of the ceramic tile, and the second chute 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com