Forming machine for producing viscose paper tube

A forming machine and viscose technology, applied in the direction of cardboard winding articles, etc., can solve problems such as troublesome, high labor costs, and cumbersome production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

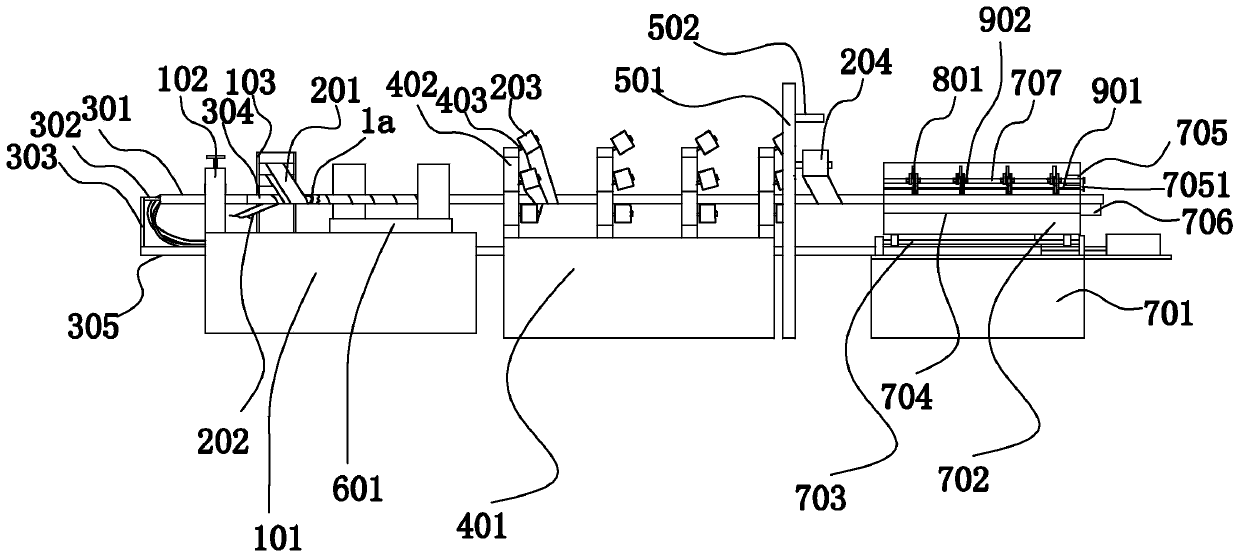

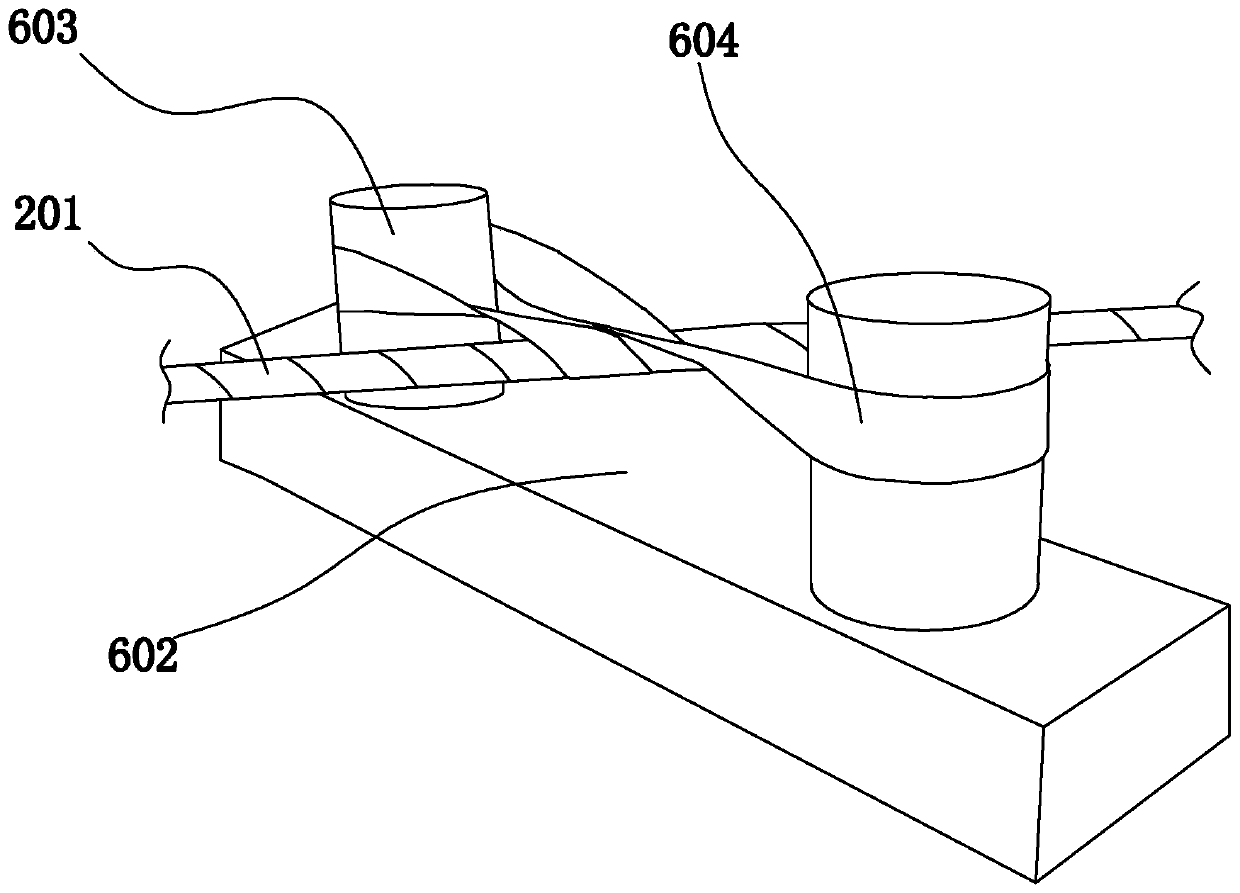

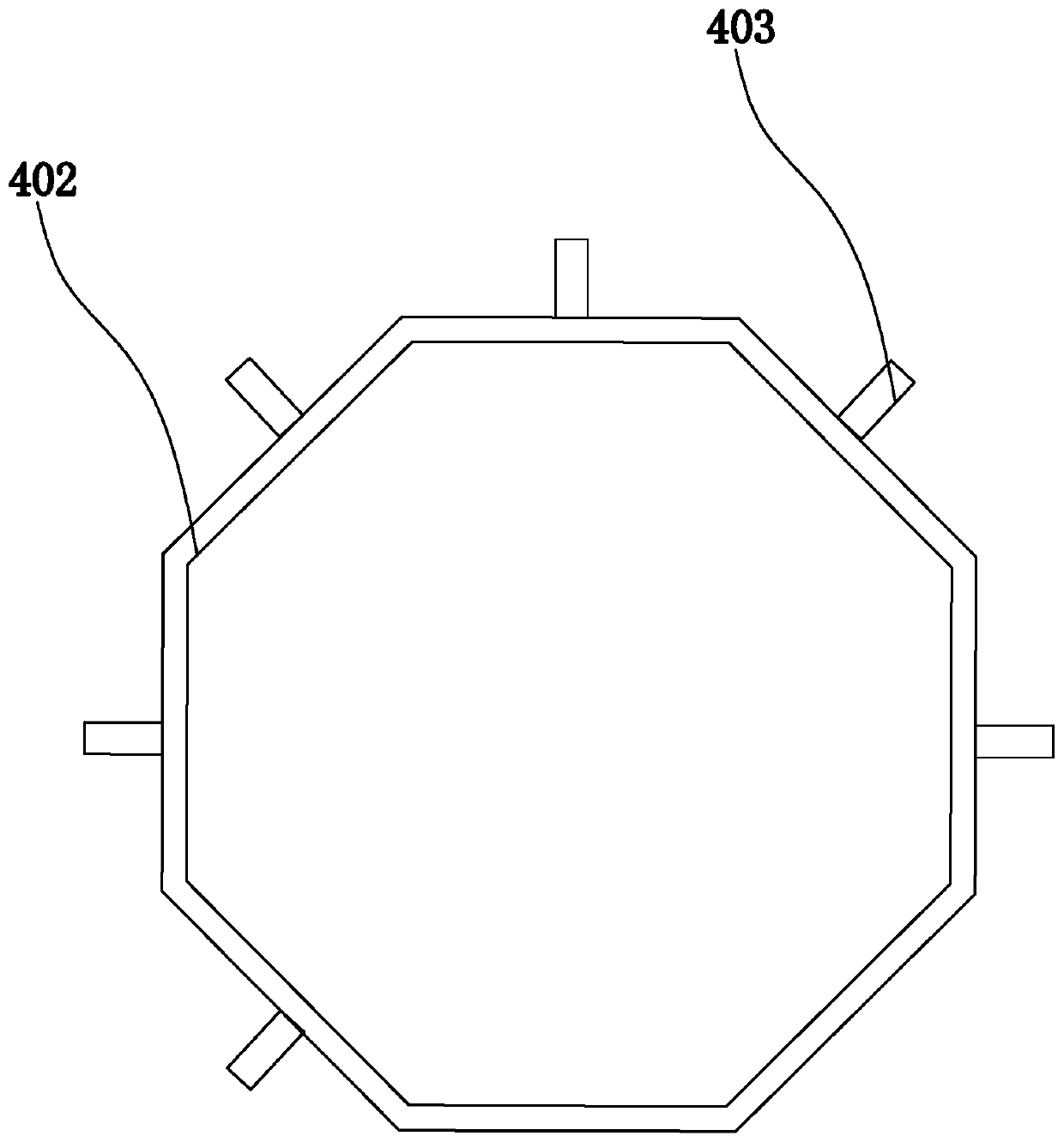

[0024] refer to Figure 1 to Figure 8 The embodiments of the present invention will be further described.

[0025] A forming machine for producing viscose paper tubes, comprising a kraft paper feeding device, a viscose paper feeding device, a wrapping paper feeding device and a forming and cutting device, the wrapping paper feeding device is placed on the viscose paper On one side of the feeding device, kraft paper feeding device, viscose paper feeding device and forming tube cutting device are arranged in a straight line.

[0026] By adopting the above-mentioned technical scheme, utilizing the kraft paper feeding device, viscose paper feeding device, wrapping paper feeding device and forming tube cutting device, the production of the paper tube and the winding of the viscose paper 203 on the paper tube are respectively completed. , plus a complete process of pasting and cutting the wrapping paper 204, replacing labor with machines, improving production efficiency and reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com