Electric handheld coil ribbon binding machine

A strapping machine and hand-held technology, which is applied in the field of electric hand-held coil strapping machines, can solve the problems affecting the repair speed and quality of motors and transformers, cannot guarantee high-quality completion, and requires a large number of personnel, etc., to improve the production process level , reduce personnel employment, and ensure the effect of bundling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings.

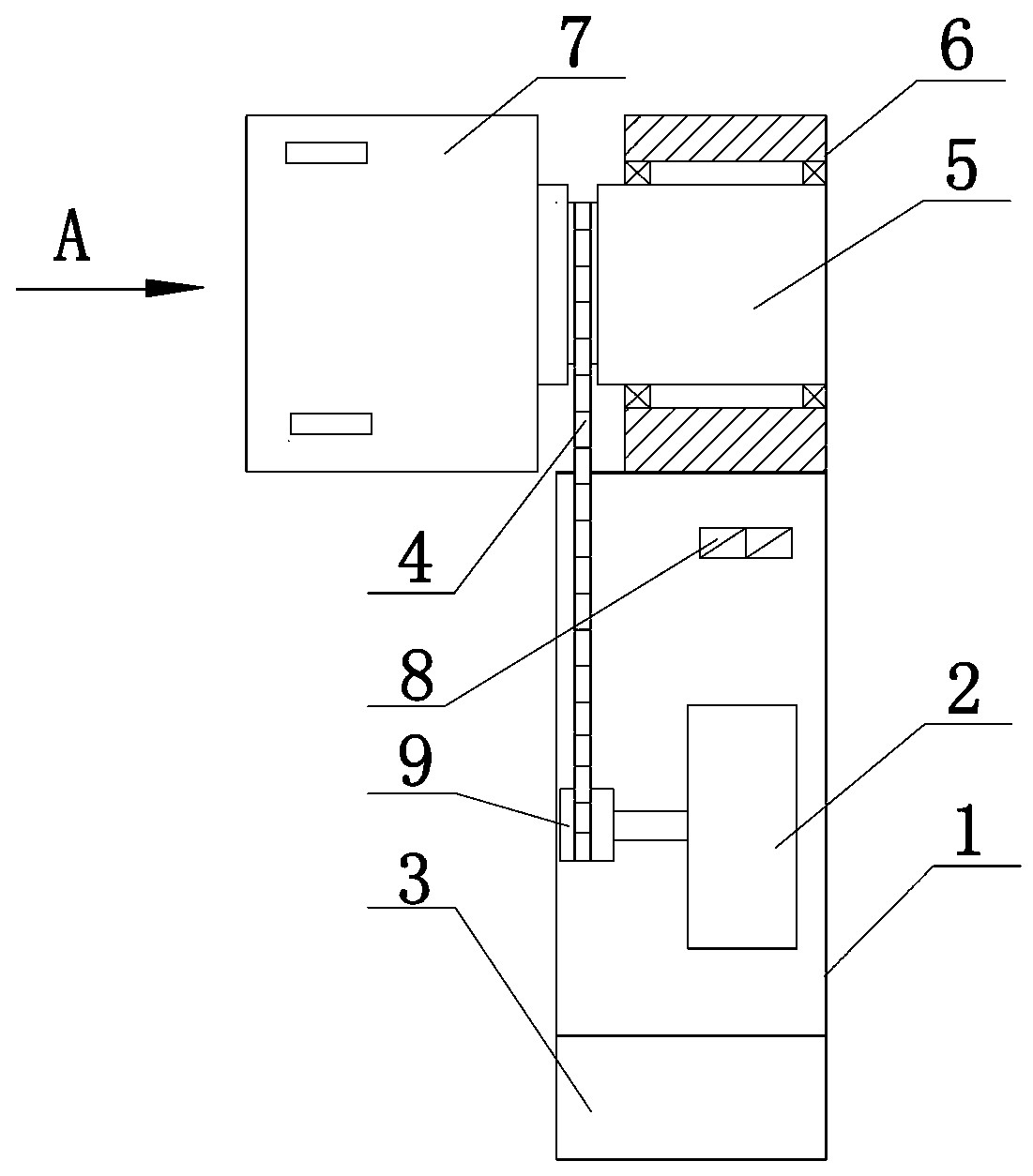

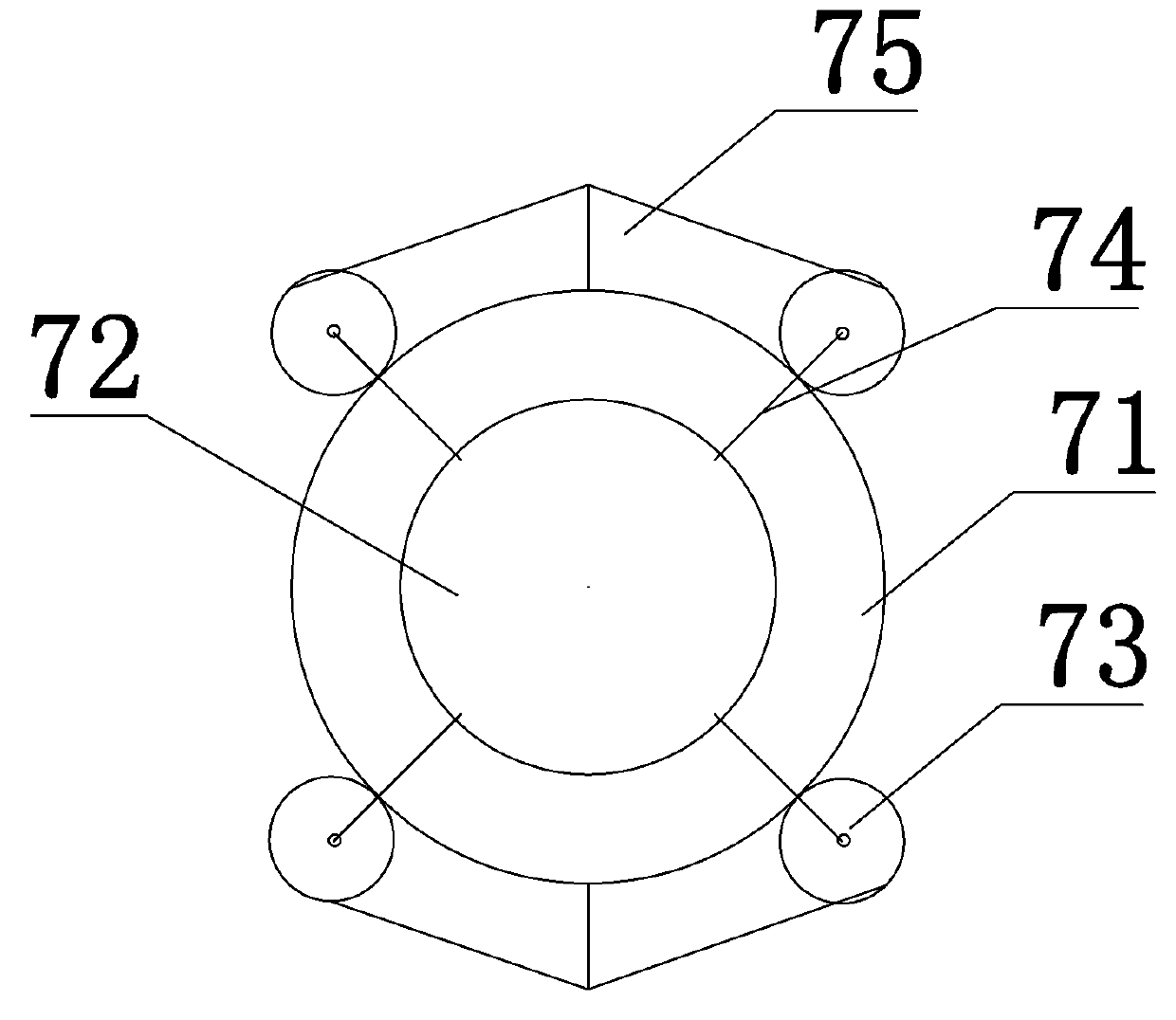

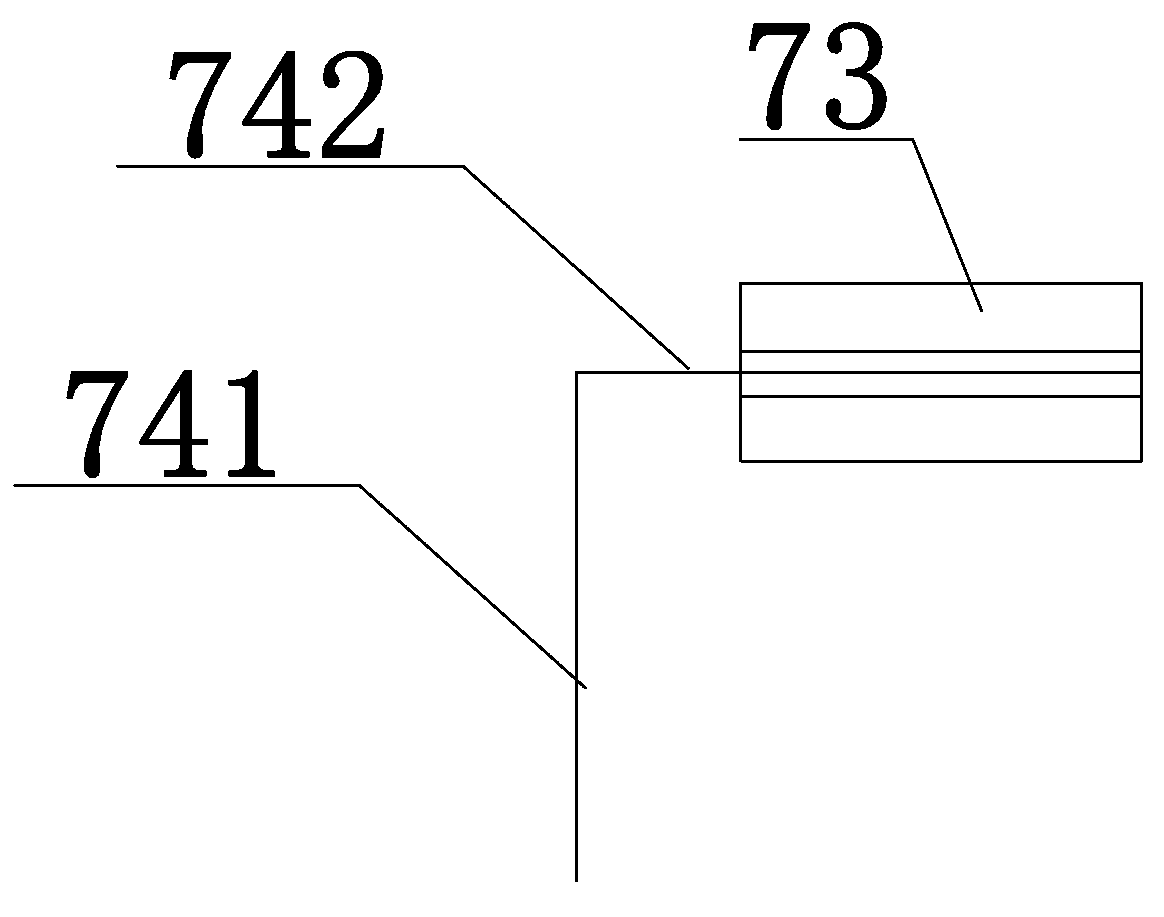

[0015] Such as Figure 1-Figure 3 As shown, a hand-held coil tie binding machine of the present invention is characterized in that it includes a hand-held housing 1, a stepping motor 2 arranged in the hand-held housing 1, is arranged on the upper part of the hand-held housing 1, and is fixedly connected to it The working head 6 and the cable tie winding device 7 have an installation cavity for installing the winder rotating shaft 5 in the working head 6, the winder rotating shaft 5 is installed in the installation cavity, and in the hand-held housing 1 There is a rechargeable battery 3 electrically connected to the stepping motor 2, the output shaft of the stepping motor 2 is connected to the gear reducer 9, and the output end of the gear reducer 9 is connected to the transmission pulley 4, and the other end of the transmission pulley 4 rotates with the winder The sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com