PVDC film electrostatic compounding device and compounding method

An electrostatic lamination and film technology, applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of affecting lamination fastness, easy to appear bubbles, etc., to improve lamination fastness, easy installation, good quality effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

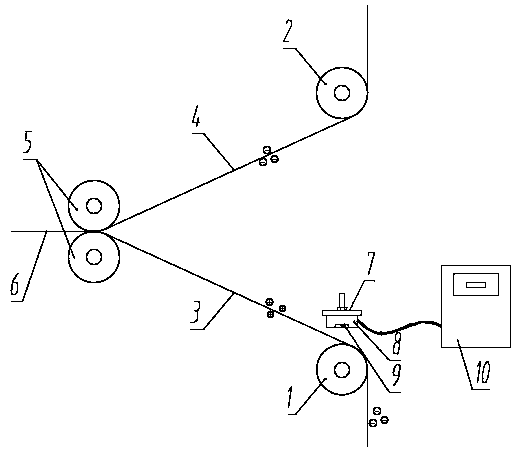

[0020] Such as figure 1 As shown, a thin film electrostatic composite device includes a frame 7 installed on the frame of the composite machine, and the frame 7 can be fixed at the film A by using the frame without additional additional structures. The frame 7 is provided with a discharge Plate 8, the discharge plate 8 is provided with a tip 9, the tip 9 faces the film A3, the discharge plate 8 is electrically connected with the electrostatic generator 10, the electrostatic generator 10 provides high voltage for the discharge plate 8, and the discharge plate 8 and the tip 9 are used to make The negative charges on the membrane A are changed to positive charges, and the electrostatic generator 10 is installed on the frame of the composite machine to facilitate the power transmission to the discharge plate.

[0021] After the double-layer packaging film is unwound by the compound machine, it reaches the metal guide roller A and the metal guide roller B respectively, and both of ...

Embodiment 2

[0023] Such as figure 1 As shown, a film electrostatic compounding method, before film A3 and film B4 are compounded, due to the friction between the roller and the film, negative charges are generated on both film A and film B, and the tip 9 on the discharge plate 8 is directed towards film A3 , the electrostatic generator 10 provides a high voltage for the discharge plate 8, the discharge plate 8 changes the original negative charge on the film A3 to a positive charge, the negative charge on the film B remains unchanged, the film A is guided by the roller A1, and the film B is guided by the roller B2 , pasting at the composite roller 5, at this time, the positive charge on the film A3 and the negative charge on the film B4 attract each other during compounding, which improves the compounding effect and ensures the quality of the composite film 6.

[0024] The discharge plate 8 is installed on the frame 7, and the frame 7 is installed on the frame of the composite machine, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com