Variable permanent magnet hybrid electromagnetic suspension system

A hybrid electromagnetic and permanent magnet technology, which is applied in electric vehicles, electric traction, transportation and packaging, etc., can solve the problems of increased suspension air gap, increased track cost, and high track accuracy requirements, so as to reduce power consumption and increase control Degree of freedom, the effect of expanding the suspension air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

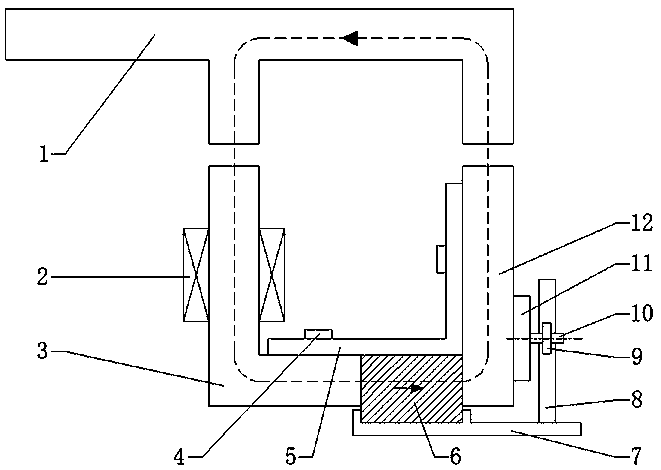

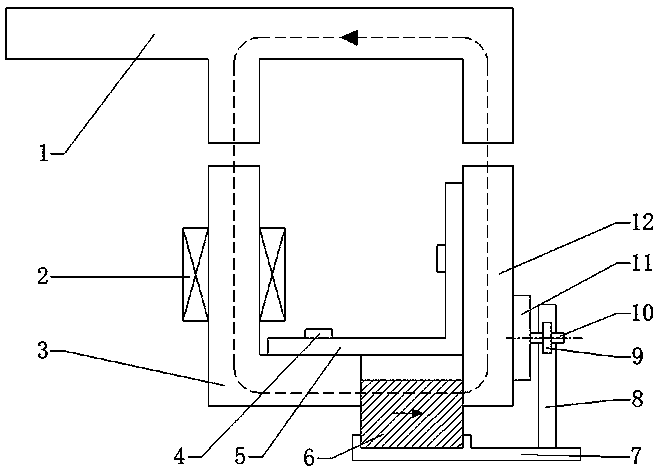

Embodiment approach 1

[0018] Embodiment 1: Combining figure 1 and figure 2 The composition of this embodiment includes a guide rail 1, a suspension coil 2, an inner electromagnet core 3, a fastening screw 4, a right-angle connecting plate 5, a movable permanent magnet 6, a movable permanent magnet fixture 7, a rack 8, a gear 9, Motor output shaft 10, disc motor 11 and outer electromagnet core 12. The guide rail 1 is made of soft magnetic material and has an F-shaped structure. The inner electromagnet core 3 and the outer electromagnet core 12 are soft magnetic silicon steel sheet materials, which are combined with the movable permanent magnet 6 to form a U-shaped structure iron core, and the inner electromagnet core 3 and the outer electromagnet core 12 use a right-angle connecting plate 5 Fixed connection with fastening screw 4. The movable permanent magnet 6 is a permanent magnet magnetized in the horizontal direction, and is located in the middle of the inner electromagnet core 3 and the out...

Embodiment approach 2

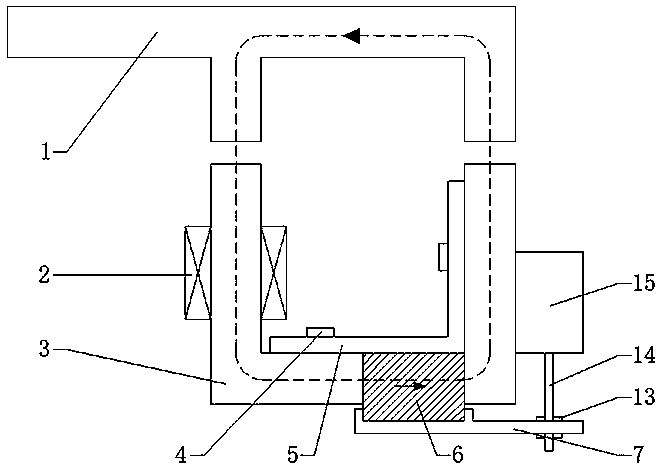

[0020] Embodiment 2: Combining image 3 and Figure 4 , on the basis of Embodiment 1, the disc motor 11 is changed to a linear motor 15, and the structure of the gear 9 and the rack 8 is canceled, and the movable permanent is directly driven by the linear motor 15 through the linear motor connecting shaft 14 and the fastening nut 13. The magnet fixture 7 drives the movable permanent magnet 6 to move, reduces the motion inertia of the system, improves the dynamic response performance of the system and the positional accuracy of the movable permanent magnet 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com