Novel rapier loom device for bevel fabric

A rapier loom and bevel technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of lower product quality and performance, uneven force on the output shaft, and short service life of the sword transmission box, and achieve Improve quality strength, increase the range of weaving process, save time and effect of quality strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

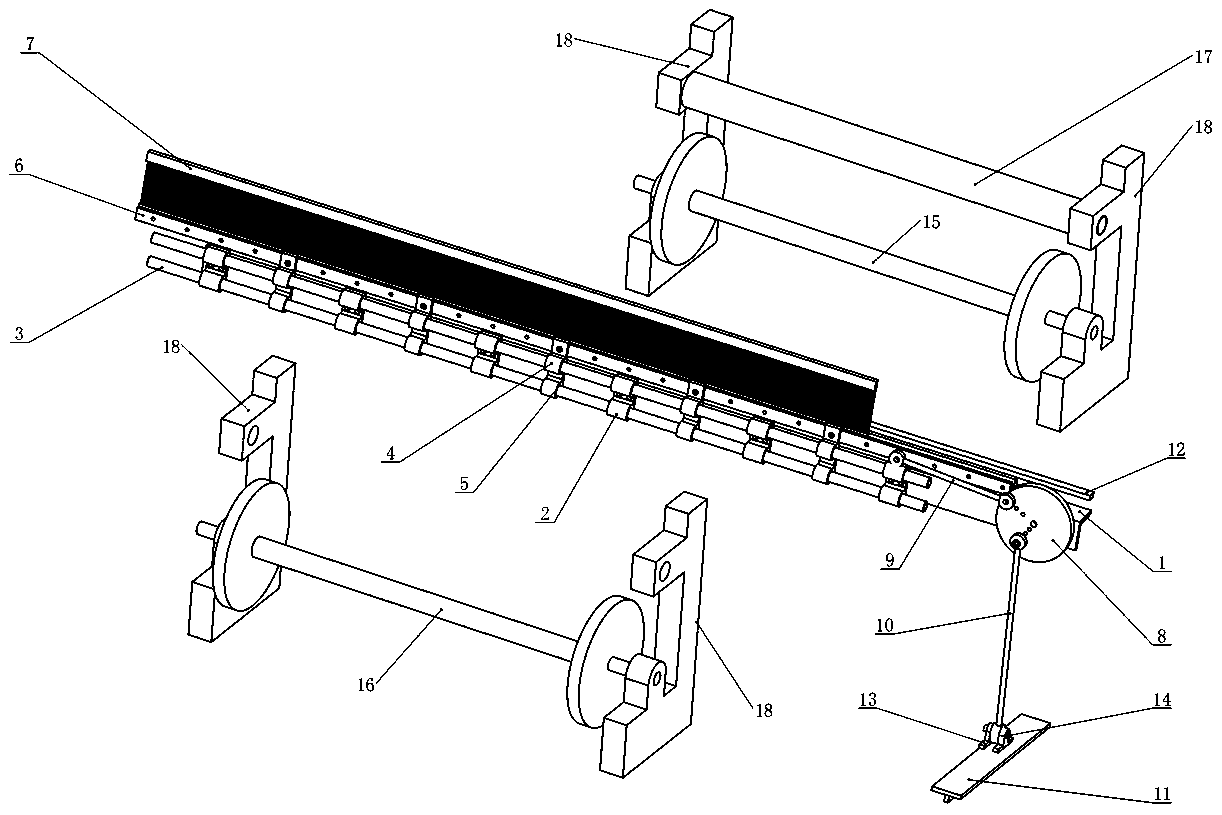

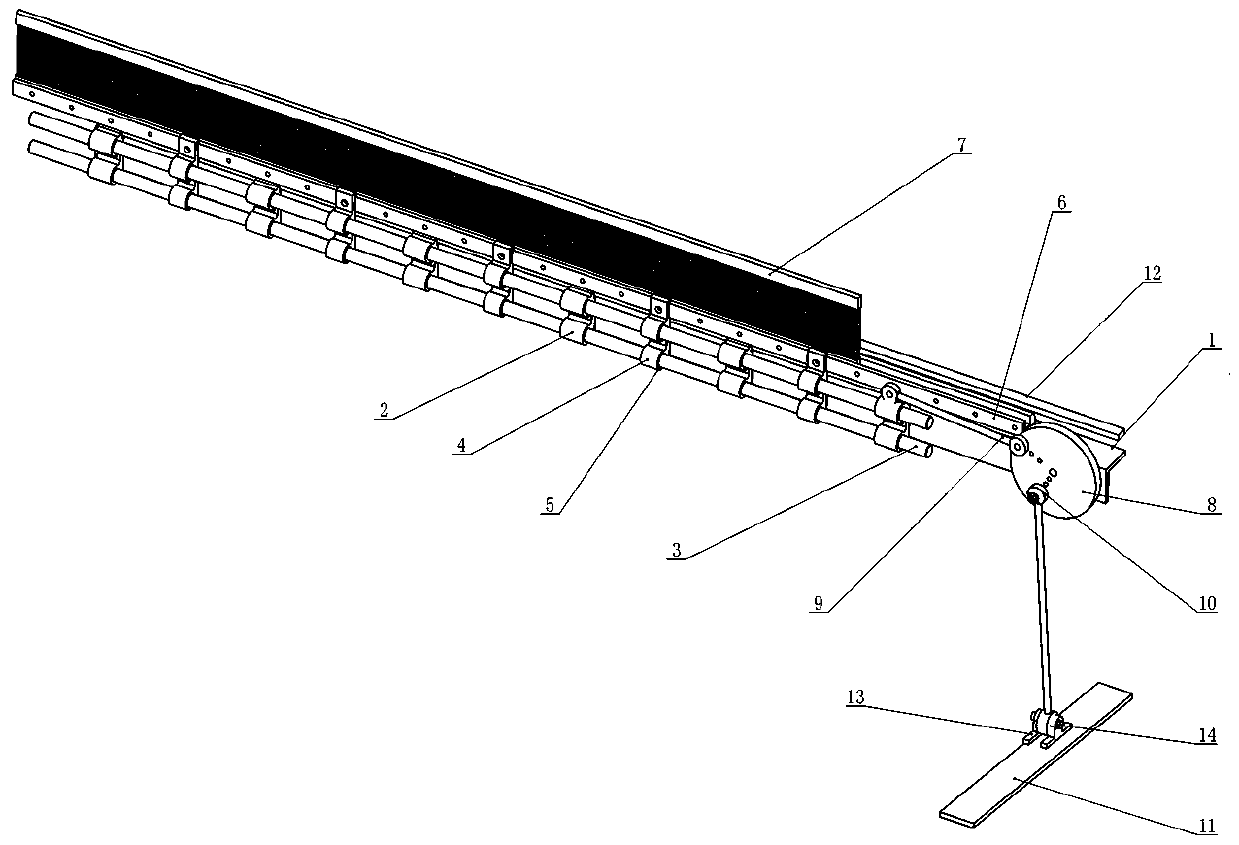

[0024] Such as Figure 1 ~ Figure 3 As shown, a new type of oblique cloth rapier loom device, its structure includes: a movable reed mechanism, a transmission mechanism, and a mechanism without a guide hook;

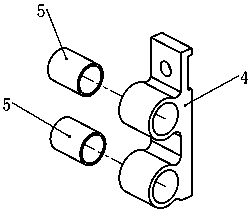

[0025] The movable reed mechanism: its structure includes steel reed 7, sley angle iron 1, guide rail 3, guide rail seat 2, sliding seat 4, copper sleeve 5, aluminum sley 6, wherein the sley angle iron 1 is installed and fixed on On the fan-shaped disk of the loom, the guide rail seat 2 is fixed on the sley angle iron 1 by screws, the guide rail 3 is fixed on the guide rail seat 2 by screws, the sliding seat 4 is installed on the guide rail 3, and can slide left and right along the guide rail 3, The aluminum sley 6 is installed on the sliding seat 4, the copper sleeve 5 is closely connected with the sliding seat 4, the steel reed 7 is installed and fixed on the aluminum sley 6, the inclination angle of the steel reed and the inclination angle of the warp yarn range from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com