Horizontal Constraint System for Split Pier Supports

A horizontally constrained, separate technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large pier size and high cost, and achieve the effect of avoiding special design and reducing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

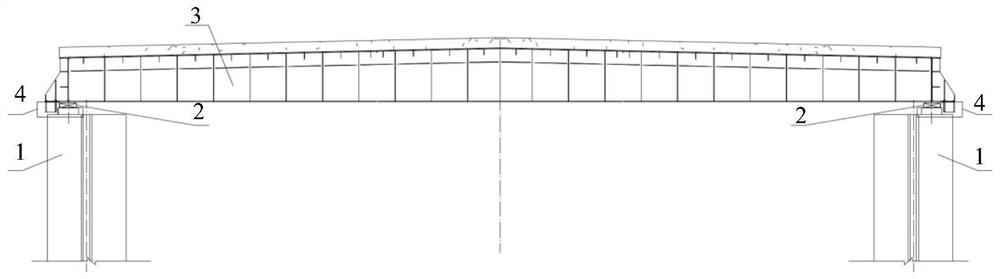

[0030] figure 1 It is a structural schematic diagram of the horizontal restraint system of the separated pier support in the embodiment of the present invention, as figure 1 As shown, the present invention discloses a horizontal restraint system for a detached pier support, comprising:

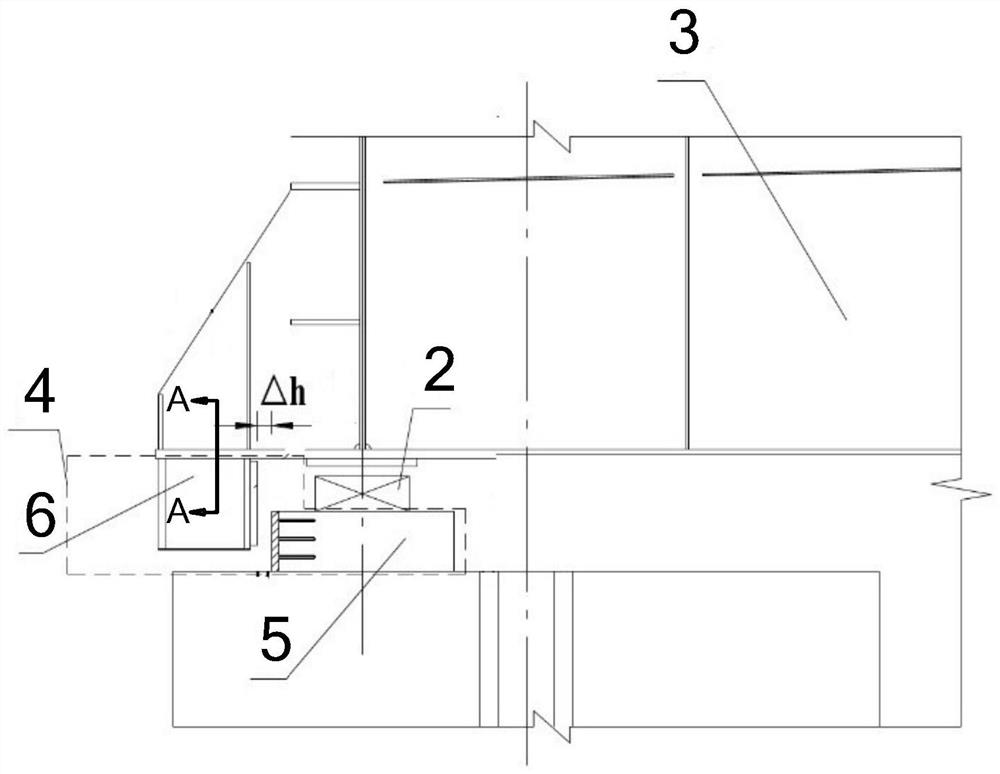

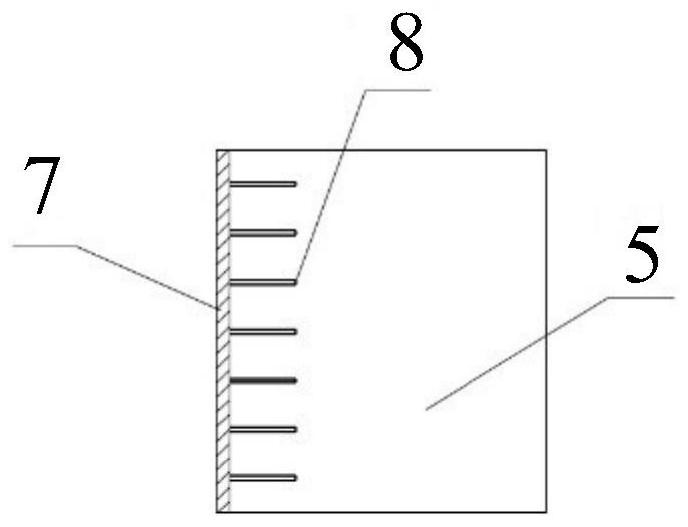

[0031] Two bridge piers 1 arranged at intervals in the direction of the transverse bridge; the top of each bridge pier 1 is equipped with a transverse movable support 2; the main girder 3 is arranged on all the transverse movable supports 2; two restraint devices 4, For limiting the lateral displacement of the main beam 3, each restraining device 4 includes: a base 5, which is arranged between the pier 1 and the lateral movable support 2, and a restraining body 6, which is arranged at the end of the main beam 3 And it is located on the outside of the base 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com