Superimposed slab shear wall structure

A technology of shear walls and laminated panels, applied to walls, building components, building structures, etc., can solve the problems of increased labor intensity, time-consuming and labor-intensive work, and low construction efficiency, so as to achieve simple structure and avoid wall skewing , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

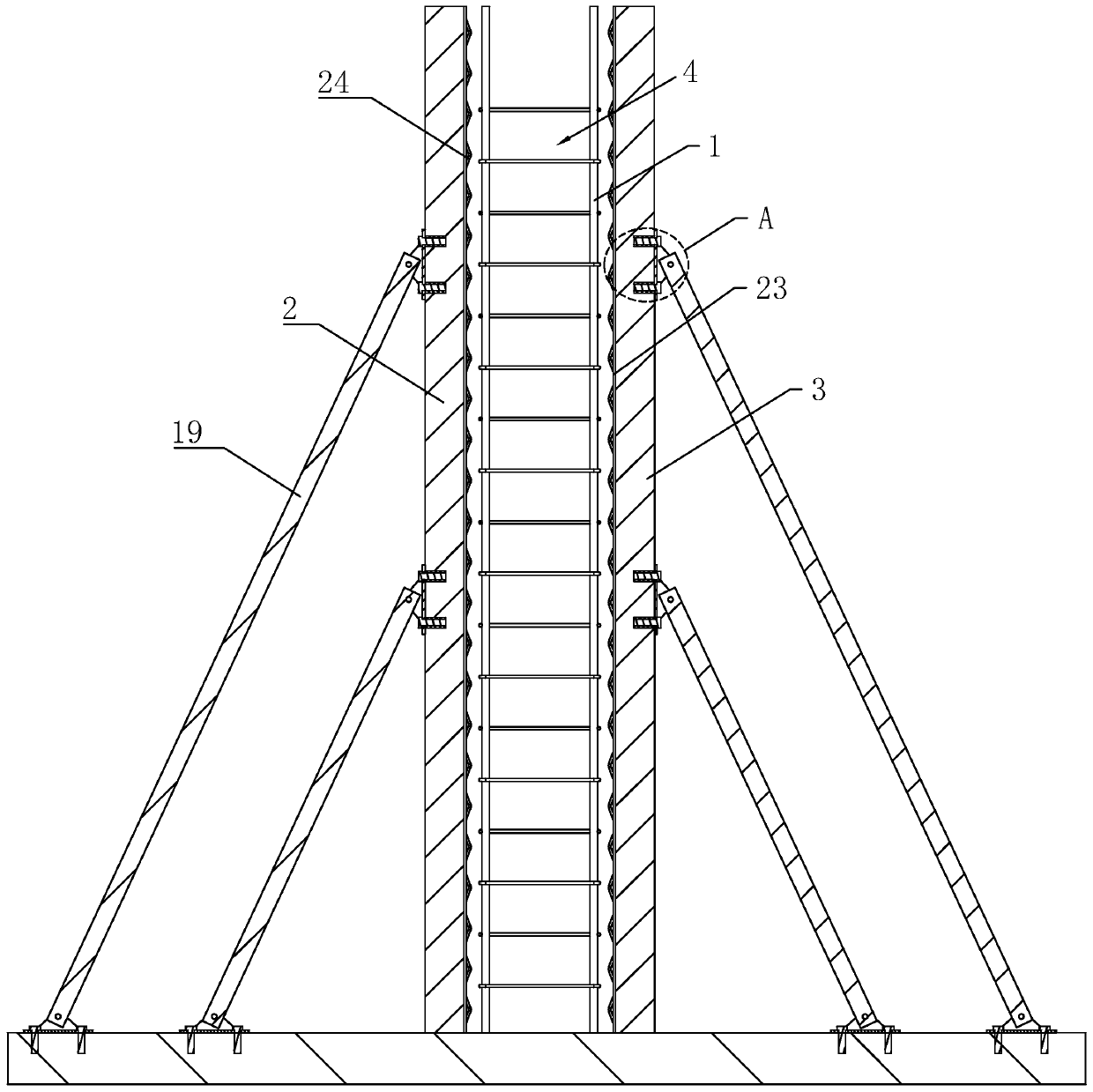

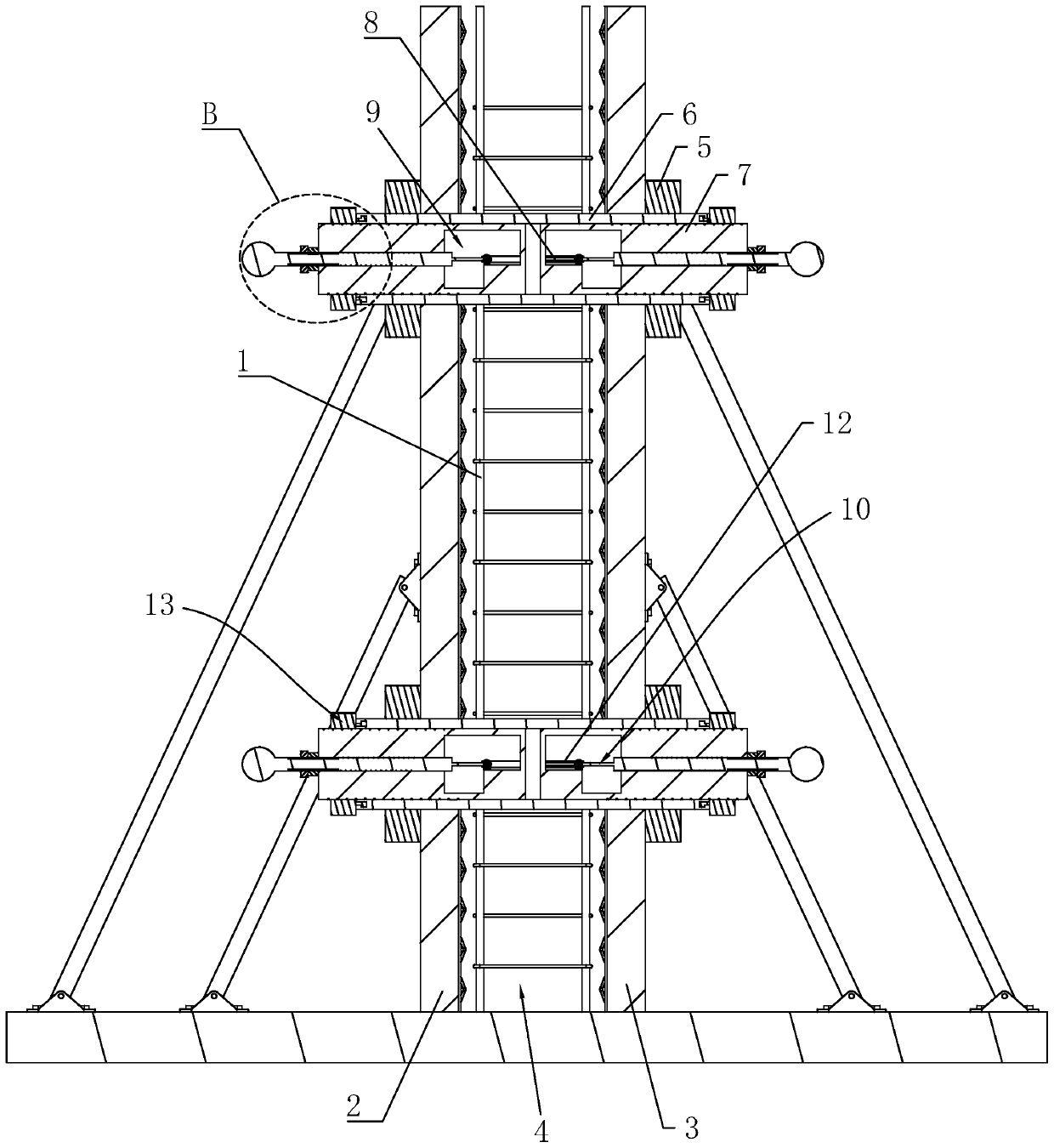

[0037] refer to figure 1, is a laminated plate shear wall structure disclosed by the present invention, comprising a reinforcement cage 1, the reinforcement cage 1 is bound and formed in a rectangular shape, an exterior wall panel 2 and an interior wall panel 3 are arranged on both sides of the reinforcement cage 1, and the interior wall A grouting space 4 for pouring concrete is enclosed between the board 3, the outer wall board 2 and the reinforcement cage 1; the inner wall board 3 and the outer wall board 2 are prefabricated boards, and concrete grout is poured into the grouting space 4, according to Design requirements, let it stand for a period of time to form a wall.

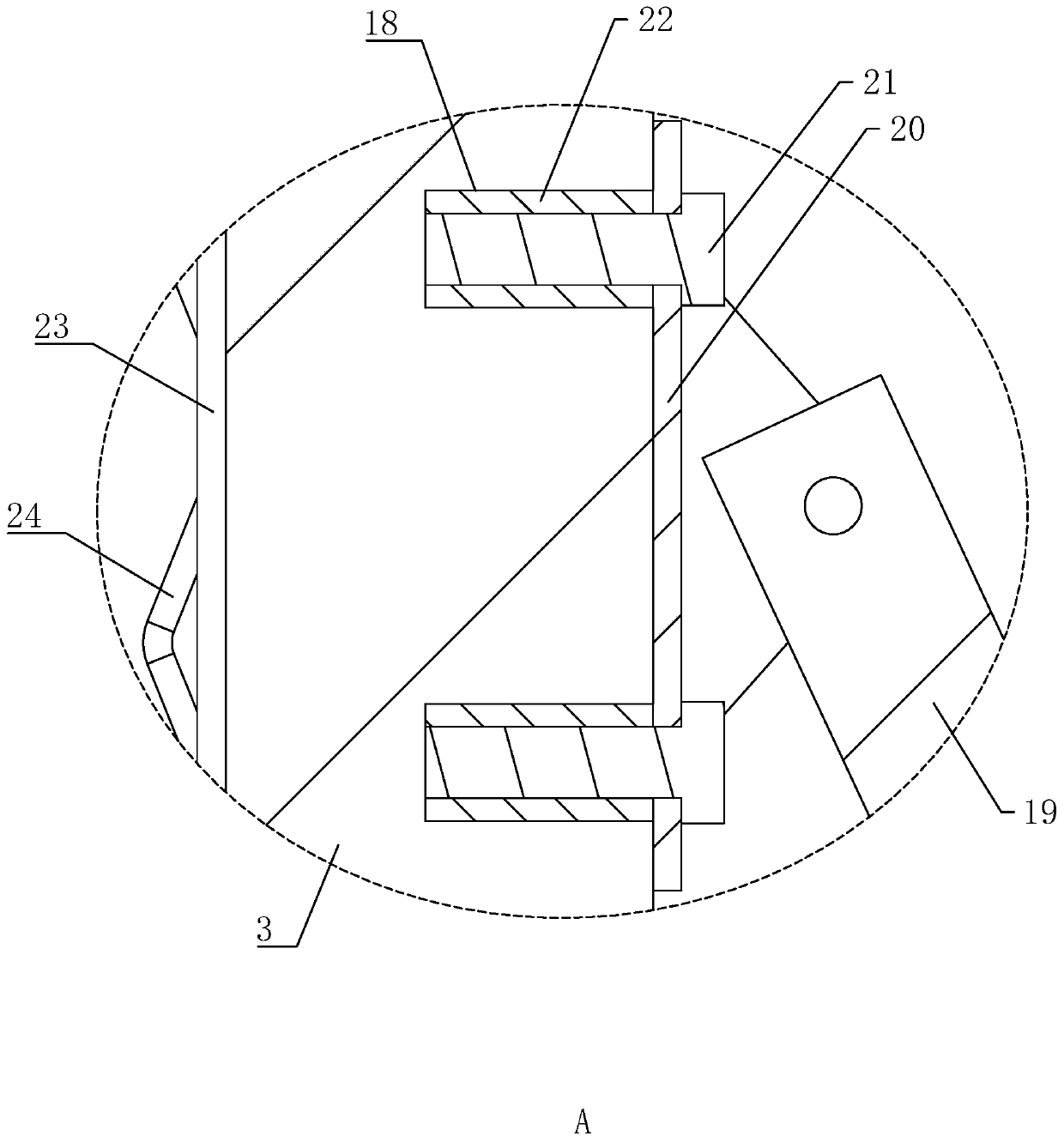

[0038] refer to figure 1 , the inner wall panel 3 and the outer wall panel 2 facing the side wall of the reinforcement cage 1 are evenly provided with a number of convex ribs 23, and a plurality of triangular reinforcing ribs 24 are uniformly distributed along the axial direction of the convex rib 23; Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com