Construction method of earth pressure balance shield arrival in subsurface tunnel in complex formation

A construction method and complex stratum technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as mud inrush, water gushing, construction methods that have not yet been formed, large construction risks and technical difficulties, etc., to ensure excavation safety, Avoid the effect of soil dehydration settlement and re-collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

[0021] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

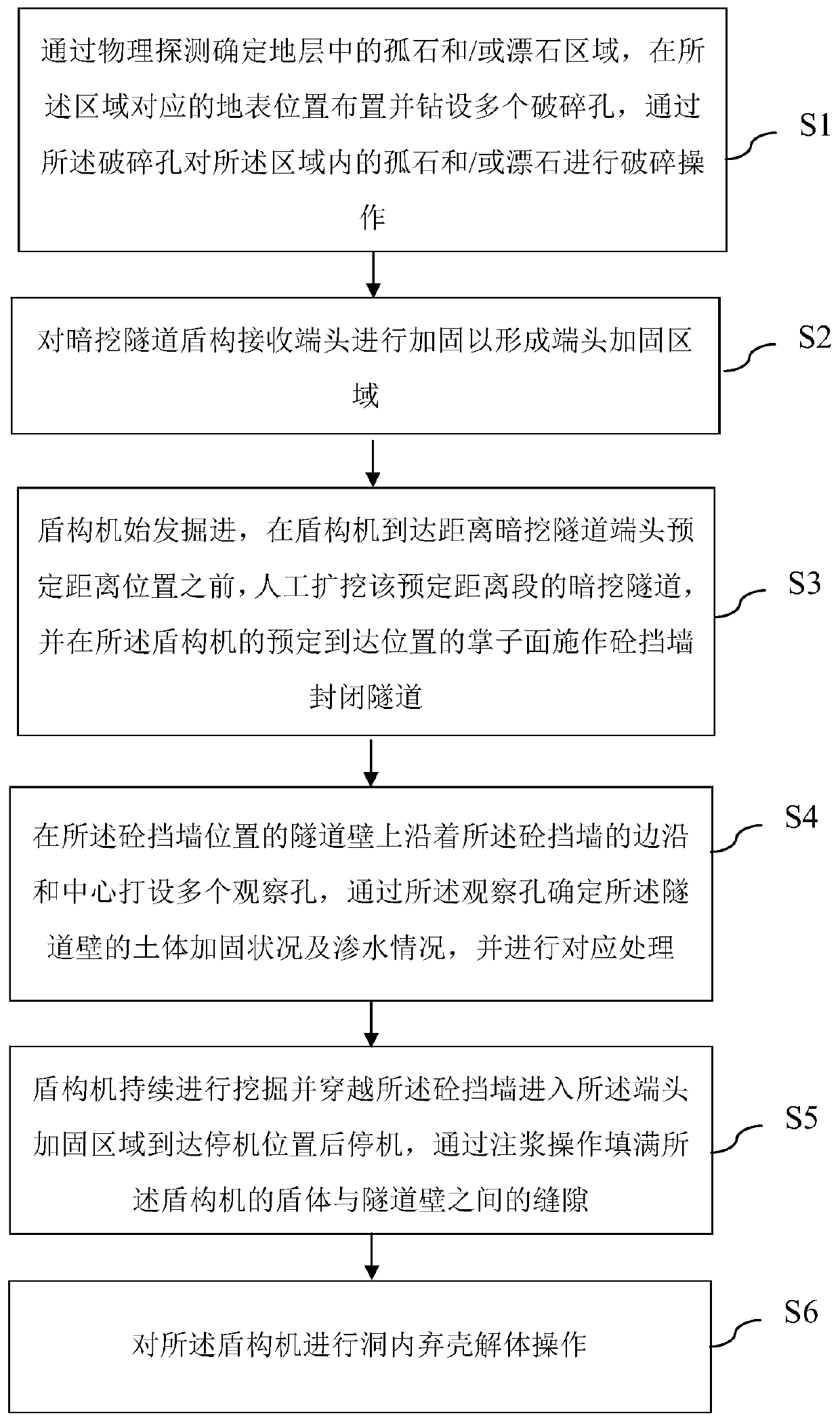

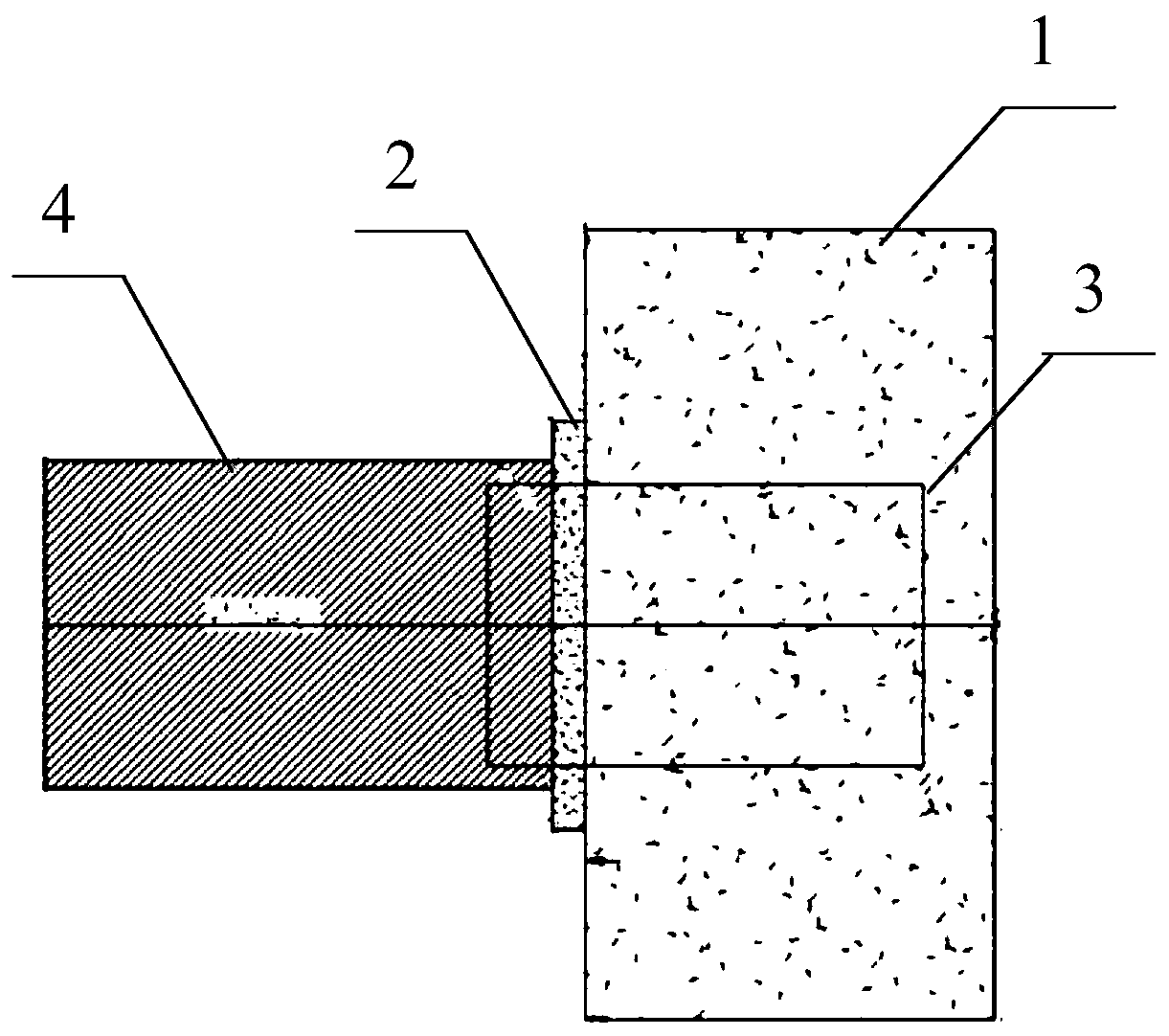

[0022] Such as Figure 1-Figure 2 As shown, the present invention provides a construction method for earth pressure shields in complex formations to be received in underground tunnels, comprising the following steps: S1) determining the boulder and / or boulder area in the formation through physical detection, corresponding to the Arrange and drill a plurality of crushing holes on the surface of the ground, through which the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com