Integrated fluidized bed garbage efficient gasification combustion furnace

A fluidized bed gasification and fluidized bed technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of excessive dioxins and the difficulty of flue gas to meet emission standards, and overcome high emissions and loose requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

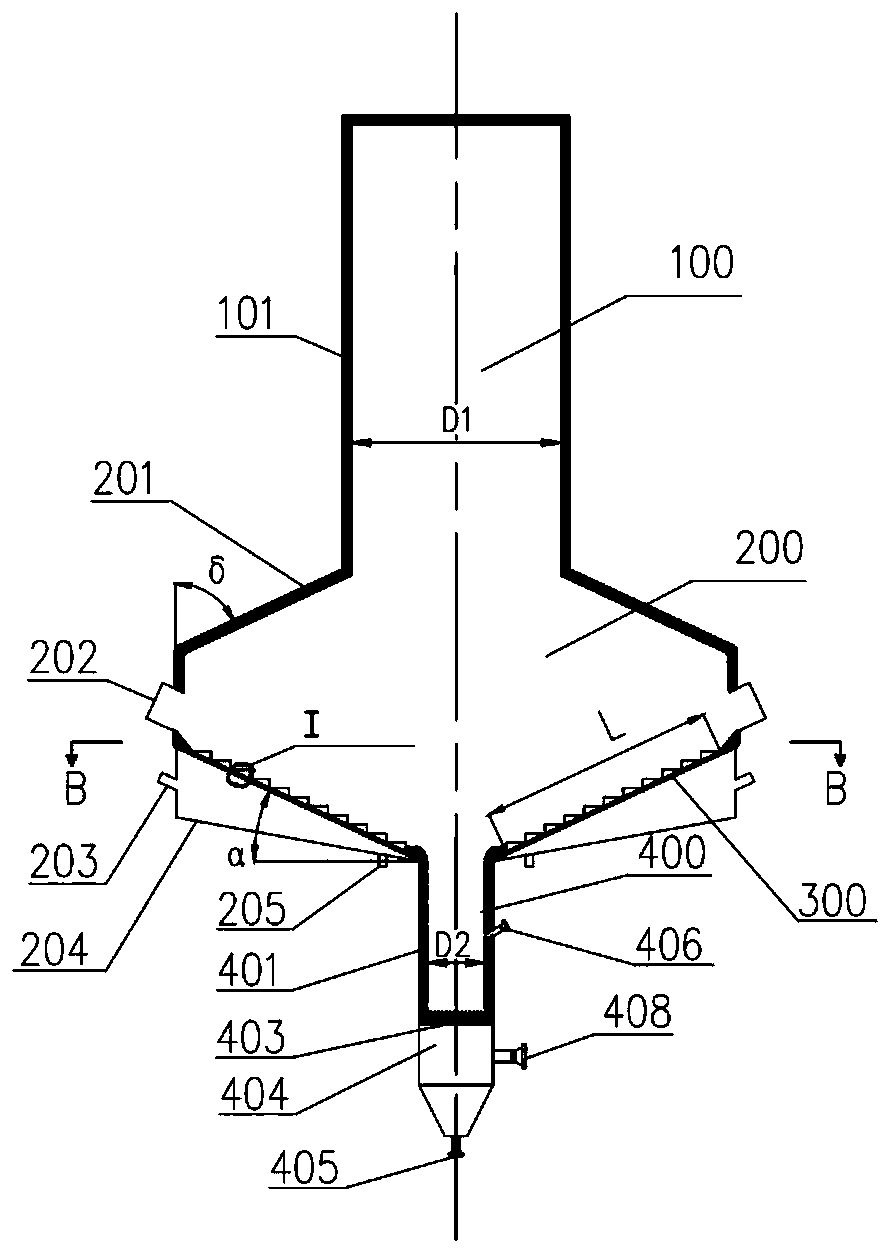

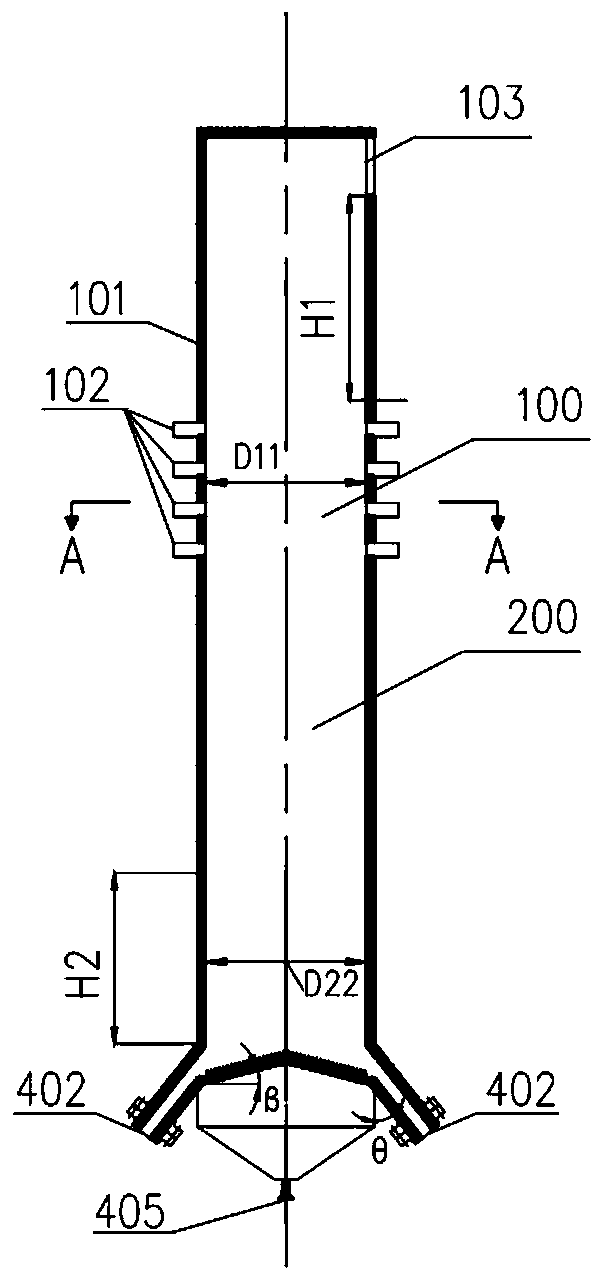

[0037] A set of integrated high-efficiency fluidized bed garbage gasification combustion furnace with a daily processing capacity of 600 tons (water content 52%), fluidized bed gasification section 400, width D2 is 1500mm, depth D22 is 3000mm, height H2 is 7m, this section is Cuboid, laying refractory material on the outside, the thickness is about 200mm.

[0038] The thickness of the refractory heat insulation layer of the heat insulation furnace wall of the dry pyrolysis section 200 is about 200mm, and the angle δ between the inclined surface and the vertical surface is 65°. The width of the grate 300 is 3m, the length L is 5m, and the inclination angle α of the grate is 25°.

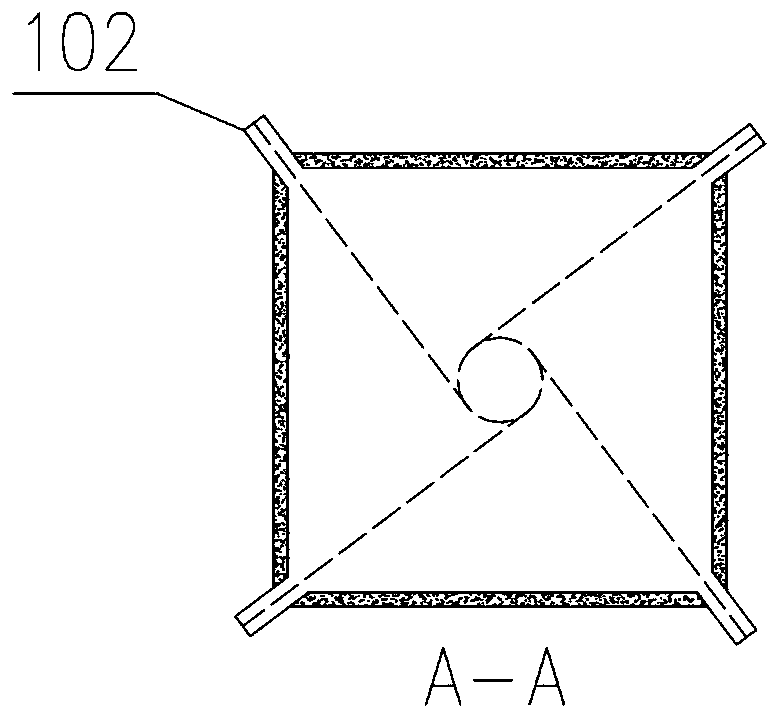

[0039] The combustible gas combustion section 100 has a depth D11 of 3000mm and a width D1 of 6000mm. It is equipped with an adiabatic furnace wall. The thickness of the fire-resistant and heat-insulating layer is about 200mm. It is equipped with 4 layers of 4-corner tangential air nozzles. The air no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com