Integrated fixed bed garbage efficient gasification combustion furnace

A fixed-bed, integrated technology, used in incinerators, combustion methods, combustion types, etc., can solve the problem that the flue gas is difficult to meet the emission standards, and achieve the effect of loose and broad requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

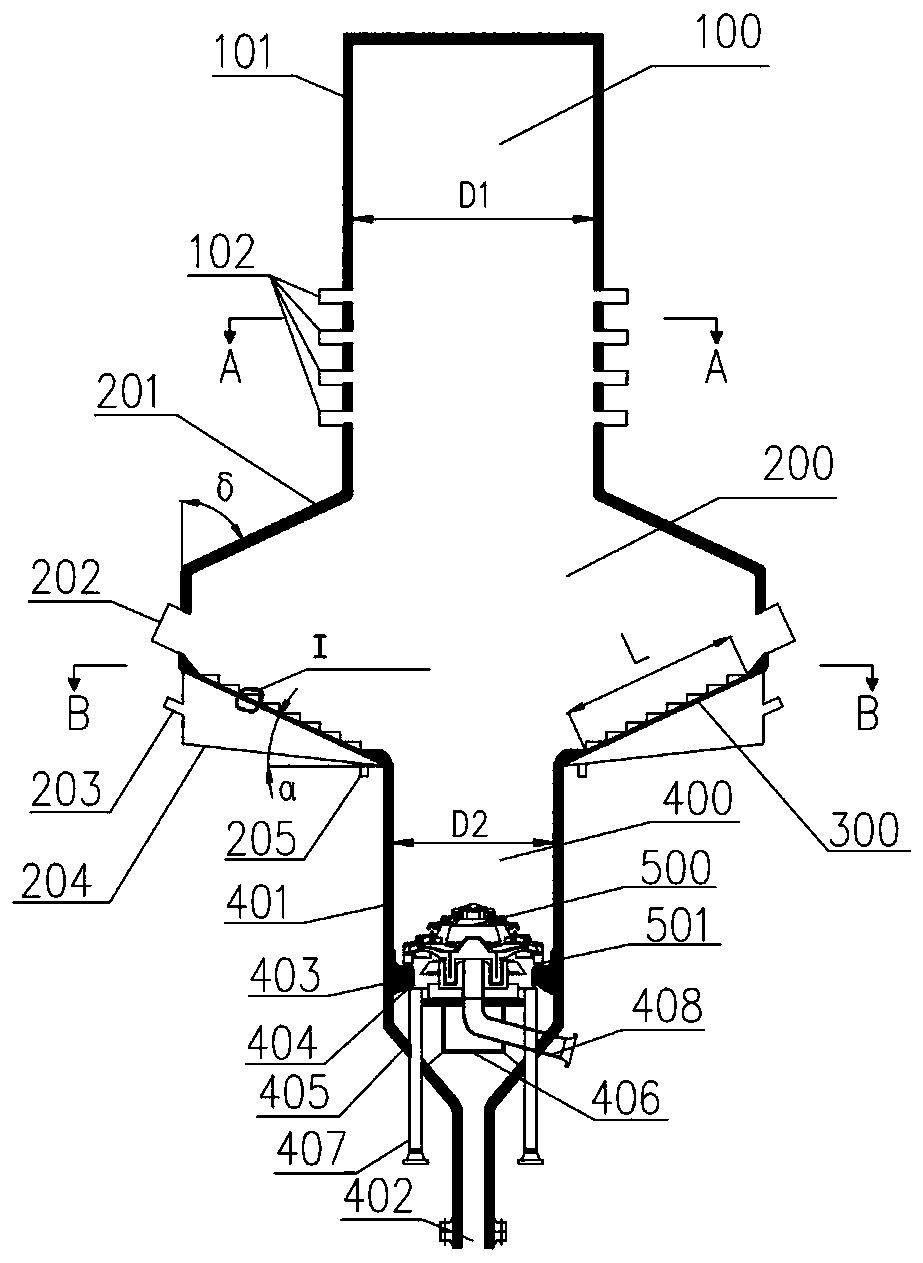

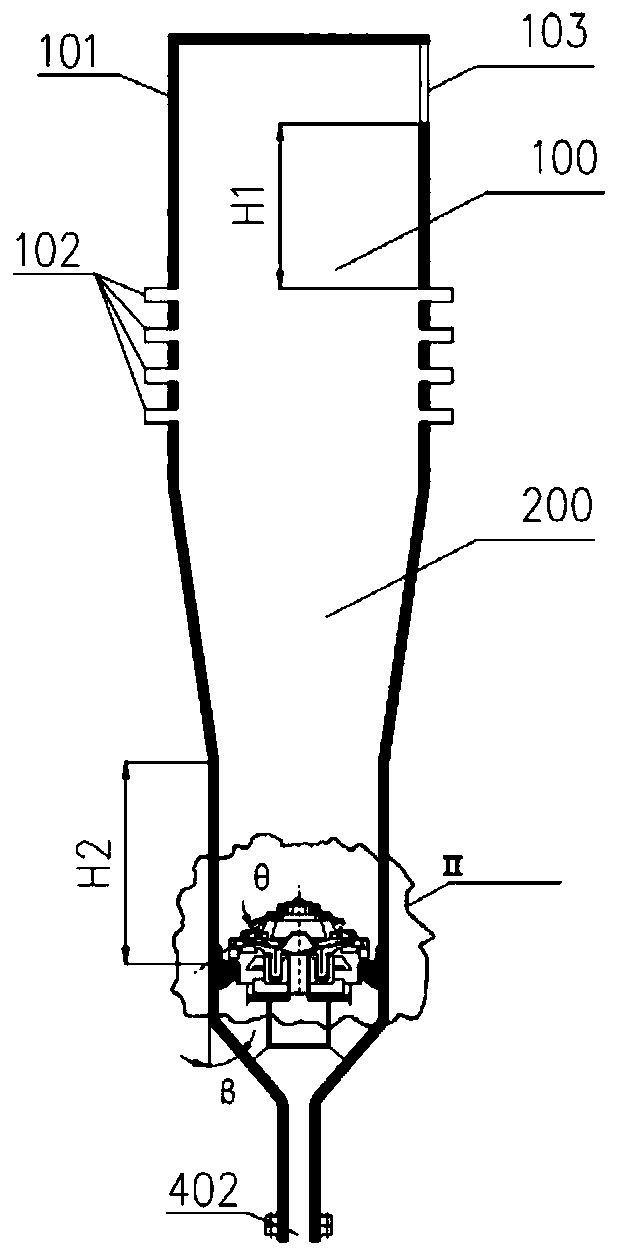

[0039] A set of integrated fixed-bed garbage high-efficiency gasification combustion furnace with a daily processing capacity of 600 tons (water content 52%). The fixed-bed gasification section 400 has an inner diameter D2 of 4000mm and a height H2 of 5m. The outside of this section is a cube and the inside is a cylinder. , The refractory material is filled between the cube and the cylinder, and the thickness is 200mm.

[0040] The thickness of the refractory heat insulation layer of the heat insulation furnace wall of the dry pyrolysis section 200 is about 200mm, and the angle δ between the inclined surface and the vertical surface is 65°. The width of the grate 300 is 4m, the length L is 4.5m, and the inclination angle α of the grate is 25°.

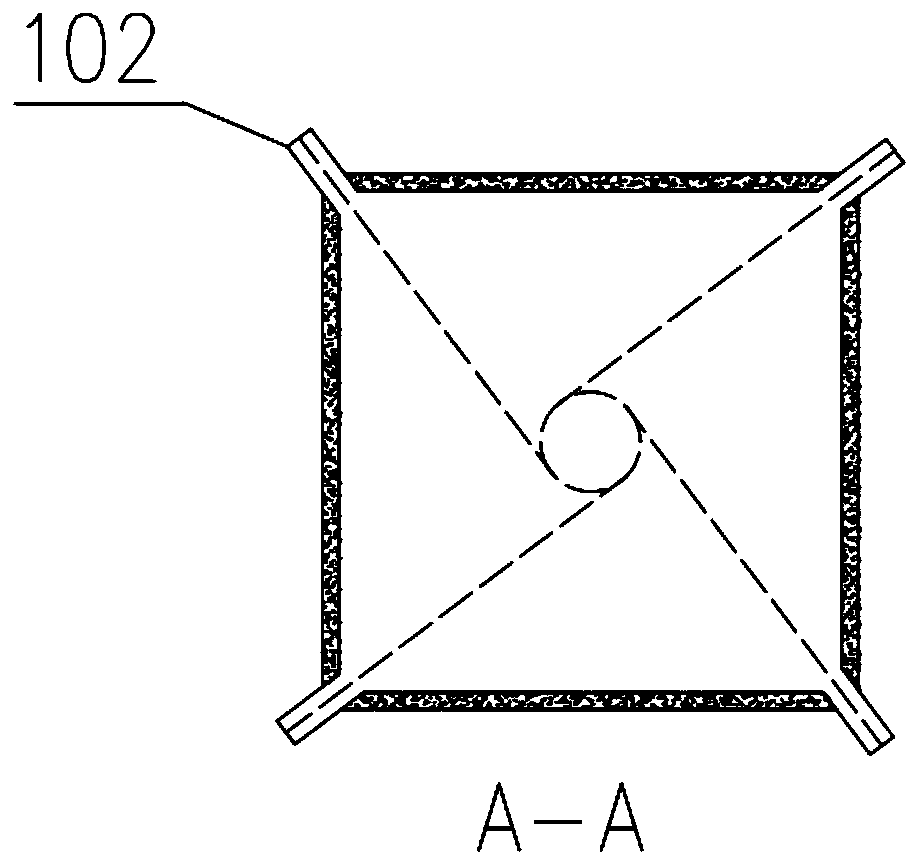

[0041] The combustible gas combustion section 100 is a cube with an inner diameter of 6m. It is equipped with a heat-insulating furnace wall. The thickness of the refractory and heat-insulating layer is about 200 mm. There are 4 layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com