Industrial waste gas detection system

A detection system, a technology for industrial waste gas, applied in measurement devices, color/spectral characteristic measurement, sampling, etc., can solve problems such as inconvenience of operation and blockage of waste gas discharge ports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

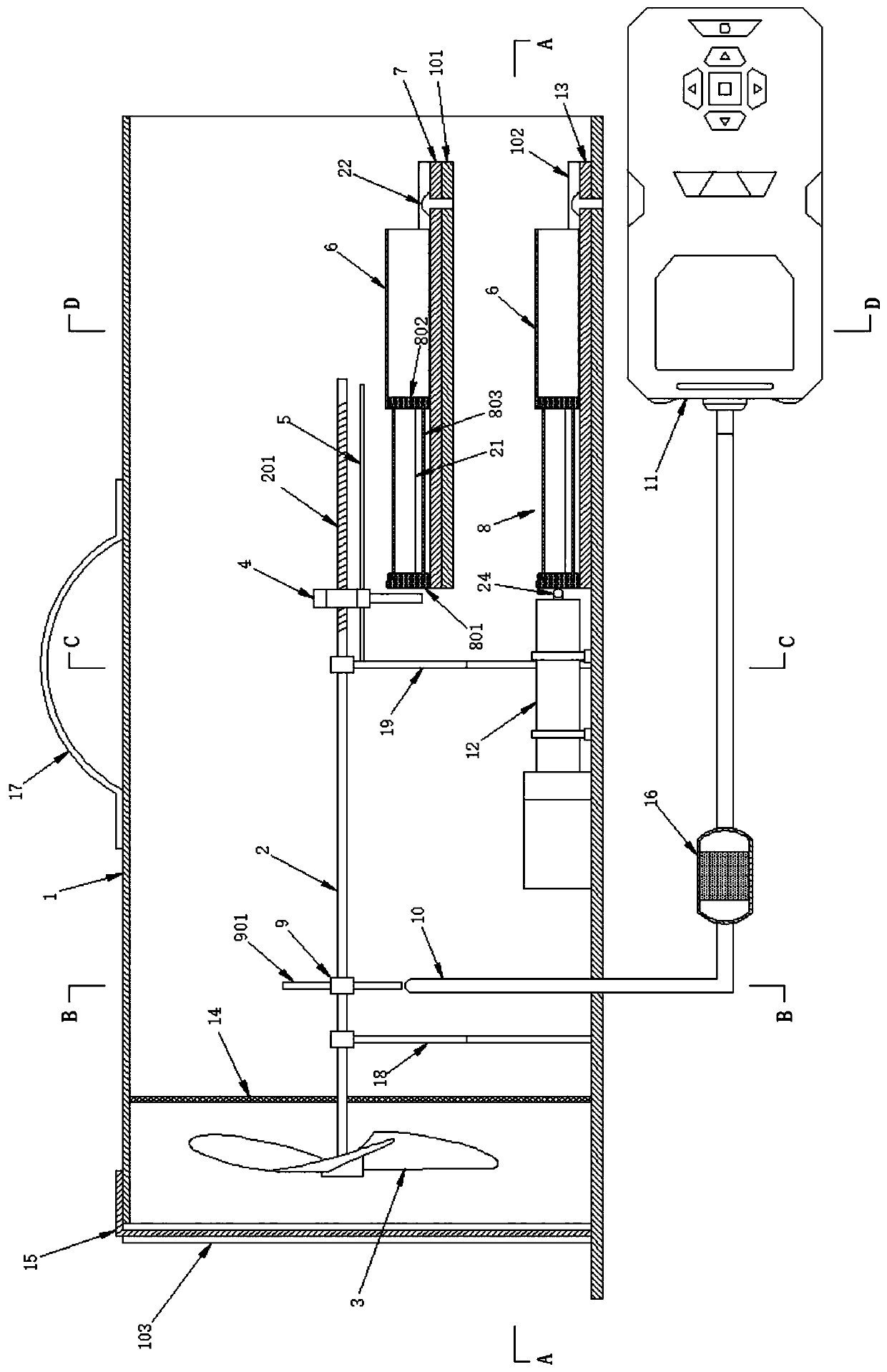

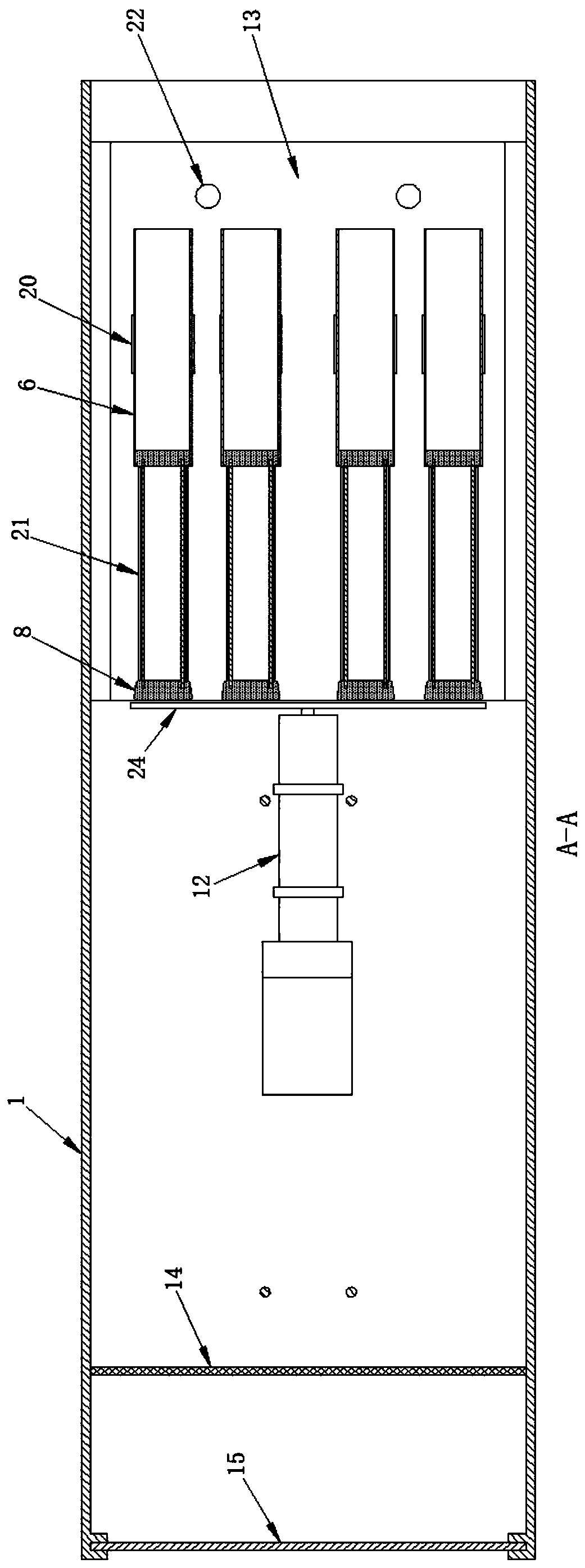

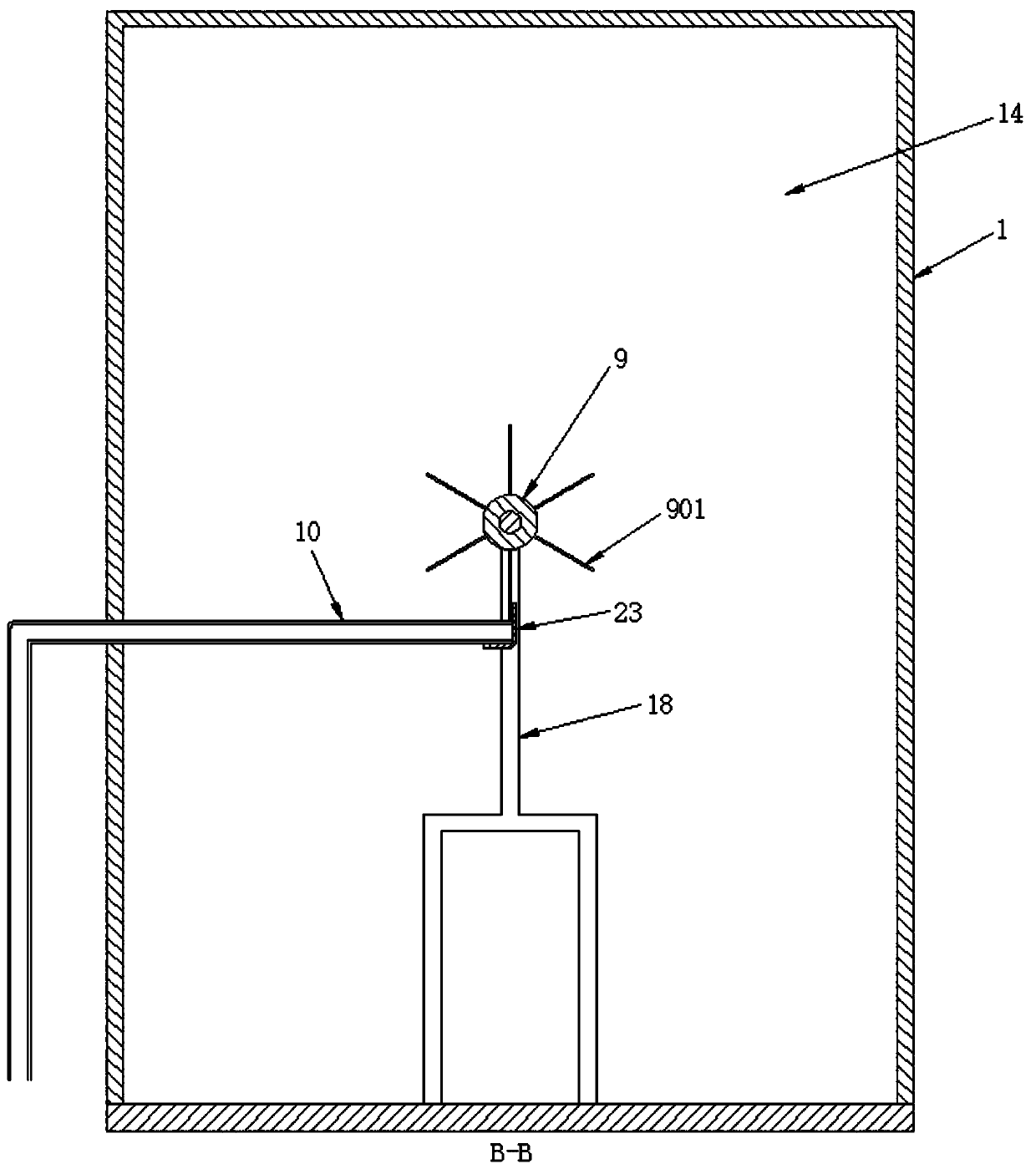

[0031] Such as Figure 1 to Figure 5 As shown, the industrial exhaust gas detection system of this embodiment includes a box body 1, a rotating shaft 2, blades 3, a screw nut 4, a guide rail 5, a sampling tube 6, a first bottom plate 7, a bottle stopper 8, a runner 9, and a drainage tube 10. Detector 11, controller, speed sensor, electric push rod 12, second bottom plate 13, filter screen 14, front-end sealing plate 15 and dryer 16;

[0032] The front and back of the box body 1 is open, the top of the box body 1 is provided with a handle 17, the first support bar 18 and the second support bar 19 are arranged in the box body 1, and the rotating shaft 2 is installed on the first support bar 18 and the second support bar. The top of the rod 19, the rotating shaft 2 is parallel to the length direction of the box body 1;

[0033] The blade 3 is installed on the front end of the rotating shaft 2, a helical section 201 is arranged at the tail of the rotating shaft 2, the screw nut 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap