A horizontal hook claw wear resistance testing machine

A wear resistance and testing machine technology, applied in the direction of testing wear resistance, measuring device, strength characteristics, etc., can solve the problems of low operating cost, affecting test results, manufacturing cost, site construction cost and operation and maintenance cost, etc. Avoid the influence of counterweight, facilitate installation and debugging, and isolate the effect of external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

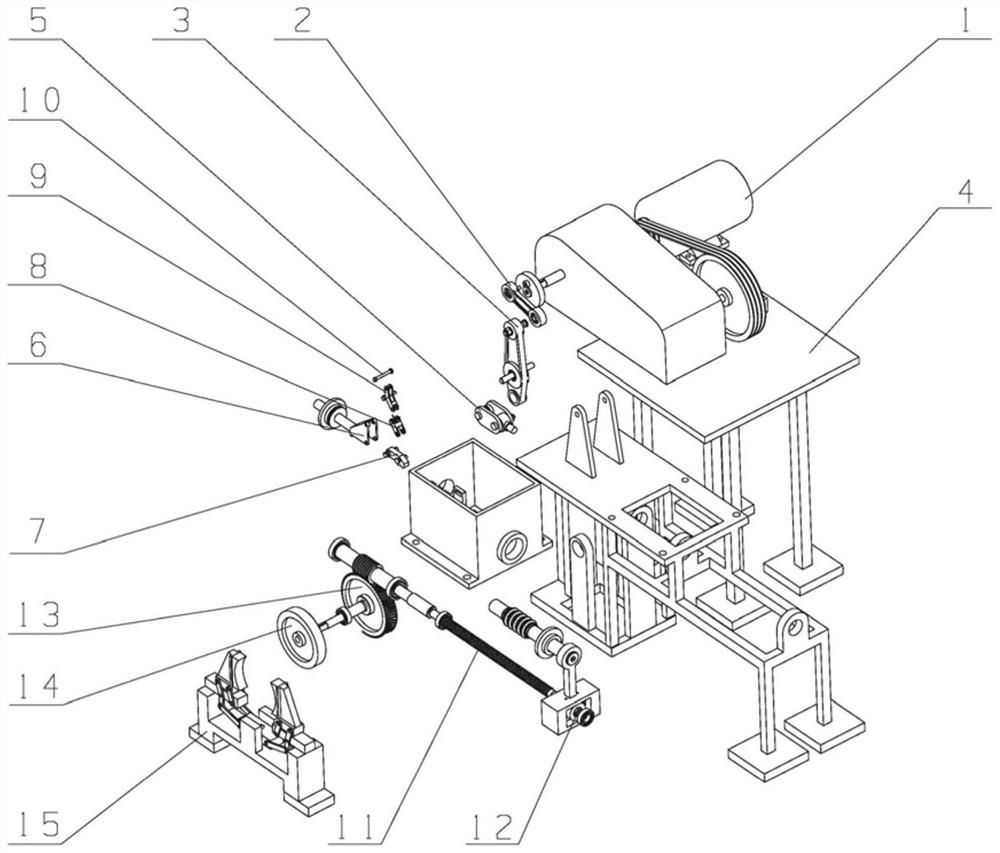

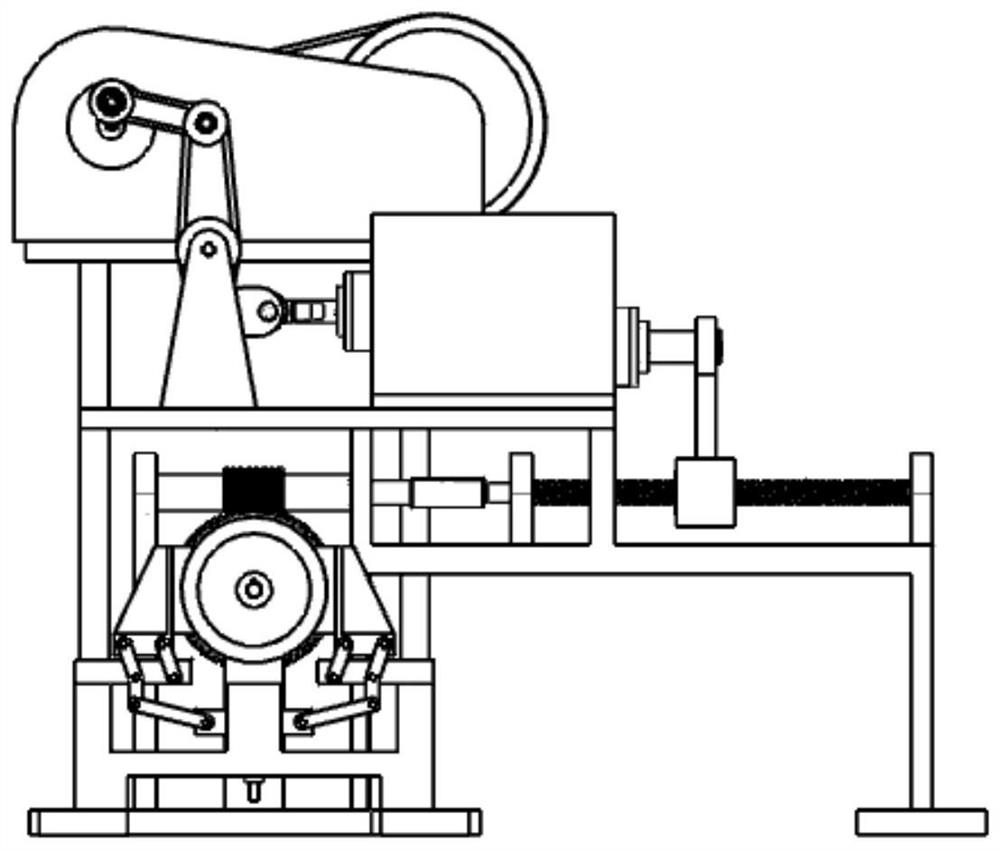

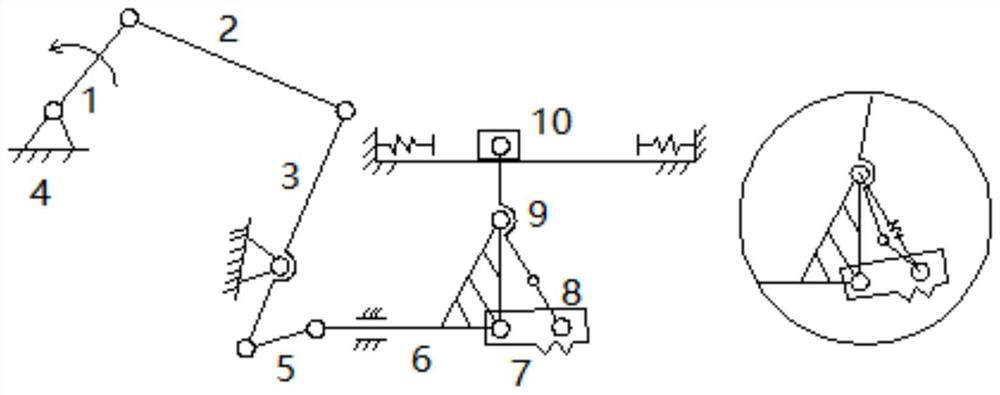

[0035] This embodiment provides a horizontal hook claw wear resistance testing machine, including a drive assembly, a simulation assembly and a loading assembly connected in sequence, the drive assembly includes a crank-rocker mechanism connected to the power source 1, and a rocker of the crank-rocker mechanism 3. A second lever is formed through the second fulcrum, the power source 1 is connected with the crank-rocker mechanism through a reducer, and the simulation assembly includes a second rod 9 and a first rod 6 connected with the rocker 3 of the crank-rocker mechanism at one end, The other end of the first rod 6 is horizontally connected with one end of the hook 7, one end of the second rod 9 is connected with the other end of the hook 7 and forms an acute angle, and the other end of the second rod 9 is horizontally slidable. The slider 10 is connected to the horizontal rail, the end of the horizontal rail is provided with a spring, the second lever 9 forms a first lever t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com