Method for operating an electric machine, device, drive device, and motor vehicle

A driving device and equipment technology, applied in the field of vehicles, can solve the problems of driving torque fluctuation, deceleration, acceleration, etc., and achieve the effect of improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

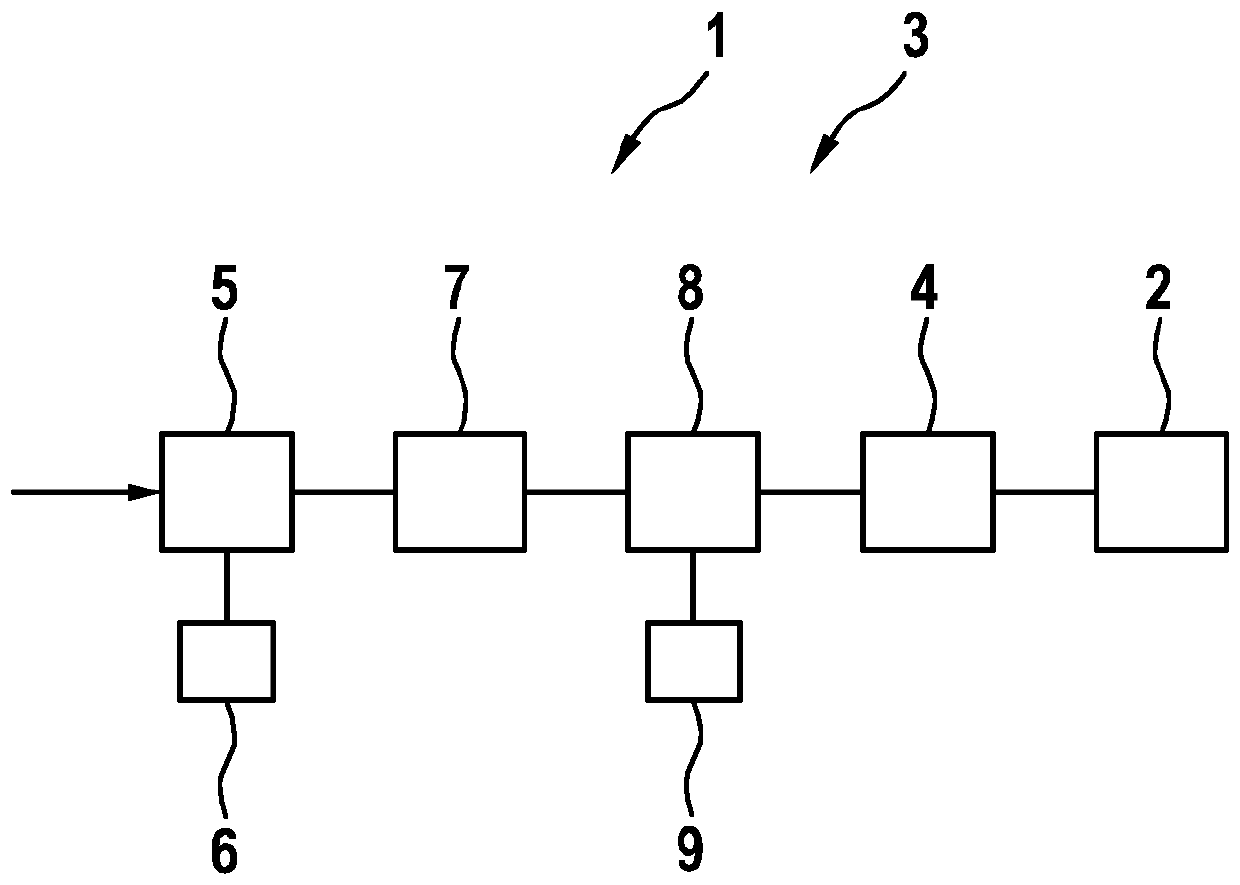

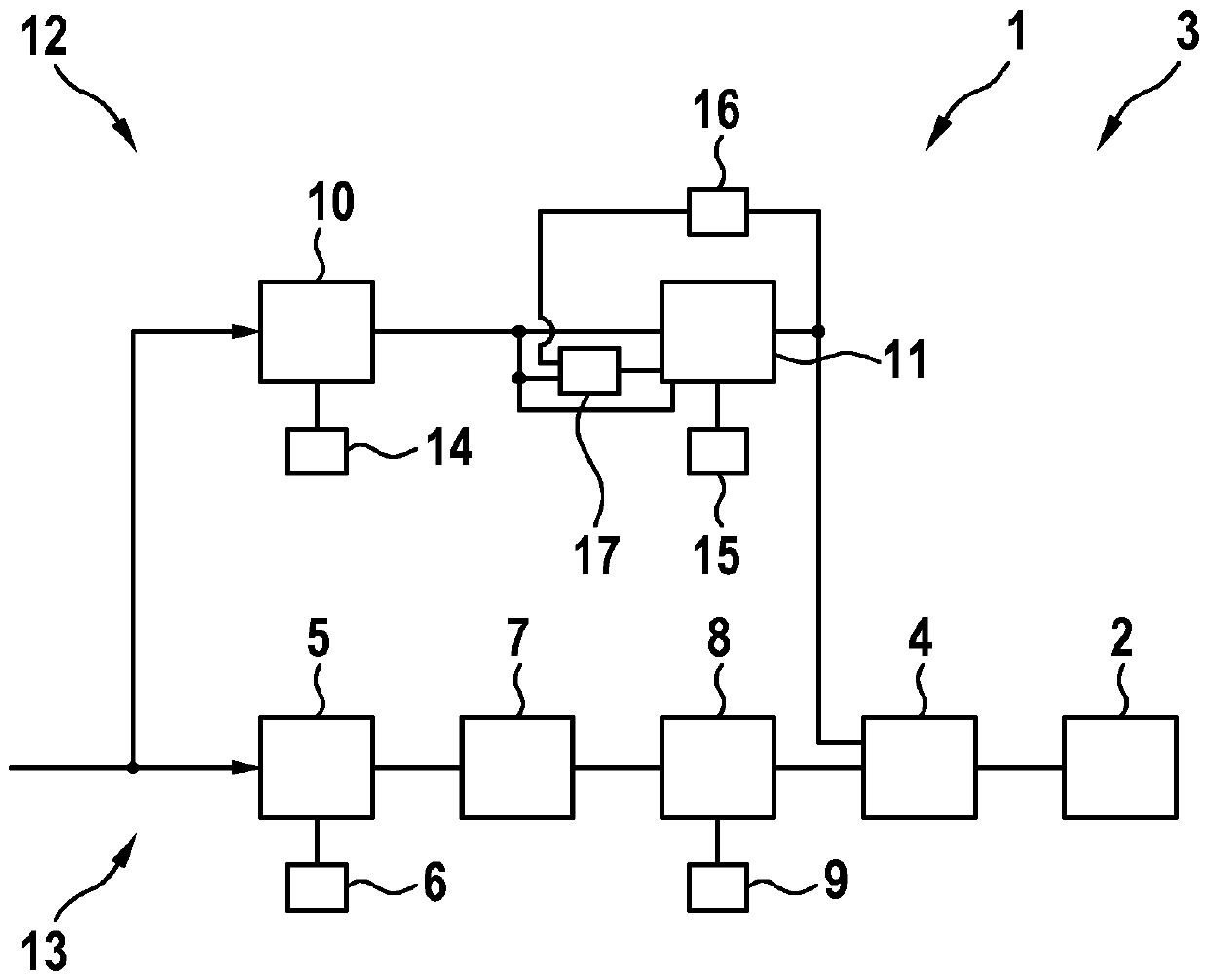

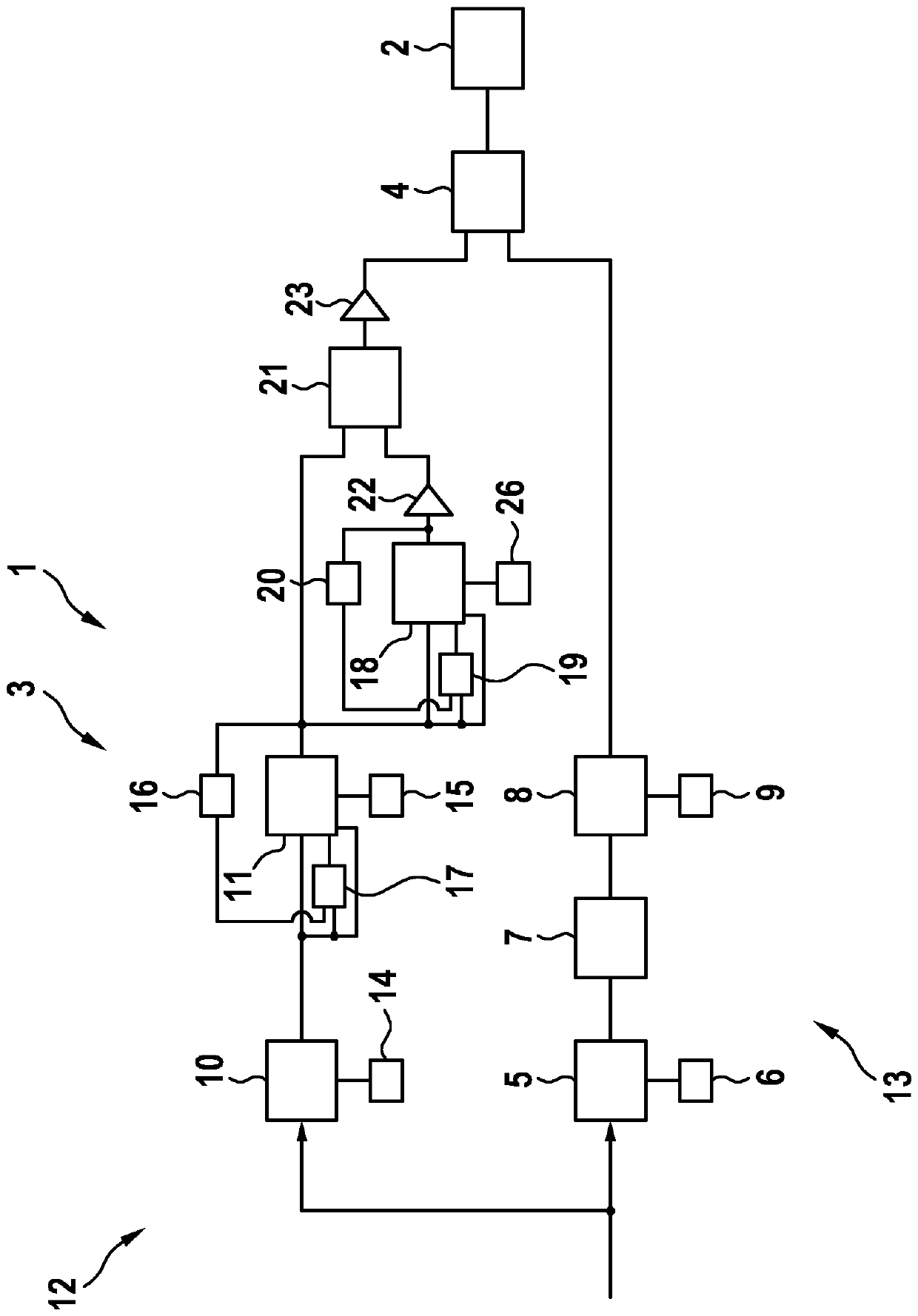

[0018] figure 1 A device 1 for operating an electric machine 2 , for example a DC or AC motor, of a vehicle 3 not shown here is shown in a simplified illustration. The device 1 has a regulating device 4 for regulating the setpoint torque of the electric machine 2 during travel as a function of the detected time-dependent rotational speed of the electric machine 2 , in particular the rotational speed of the drive shaft of the electric machine 2 . Optional detection of multiple rotational speeds or rotational speed curves over time.

[0019] The rotational speed or the rotational speed of the drive shaft is preferably detected by means of a sensor, in particular a rotational speed sensor.

[0020] The device 1 also has a first high-pass filter 5 for differentiating the detected rotational speed as a function of time. The detected rotational speed or the rotational speed profile formed by at least two rotational speeds and the time constant T via the switching device 6 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com