Connection device for a turbocharger, and turbocharger

A connection device, exhaust gas turbine technology, applied in the direction of gas turbine device, rod connection, exhaust device, etc., can solve the problems of connection device expansion, wrong positioning, etc., and achieve the effect of improving the resistance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

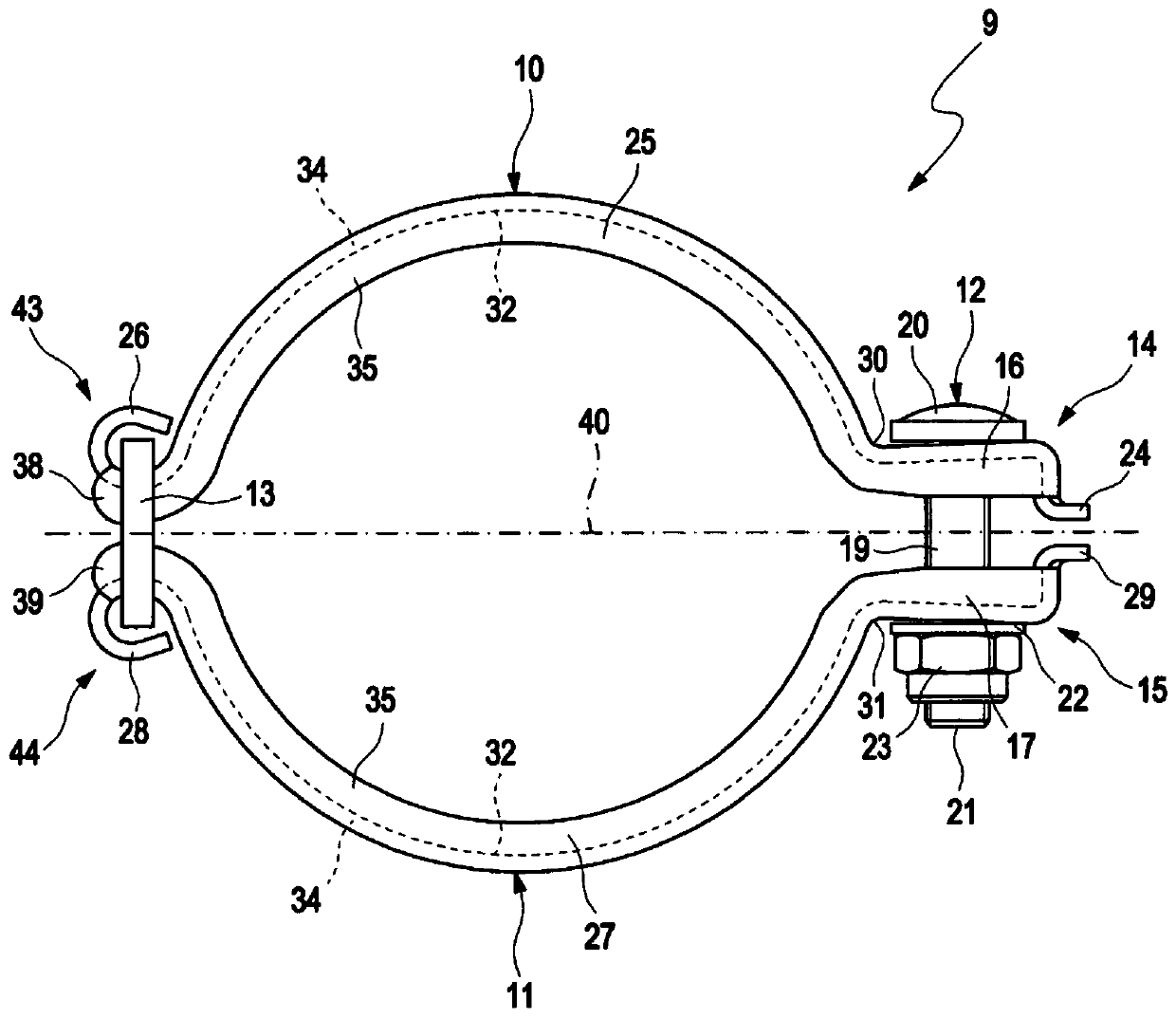

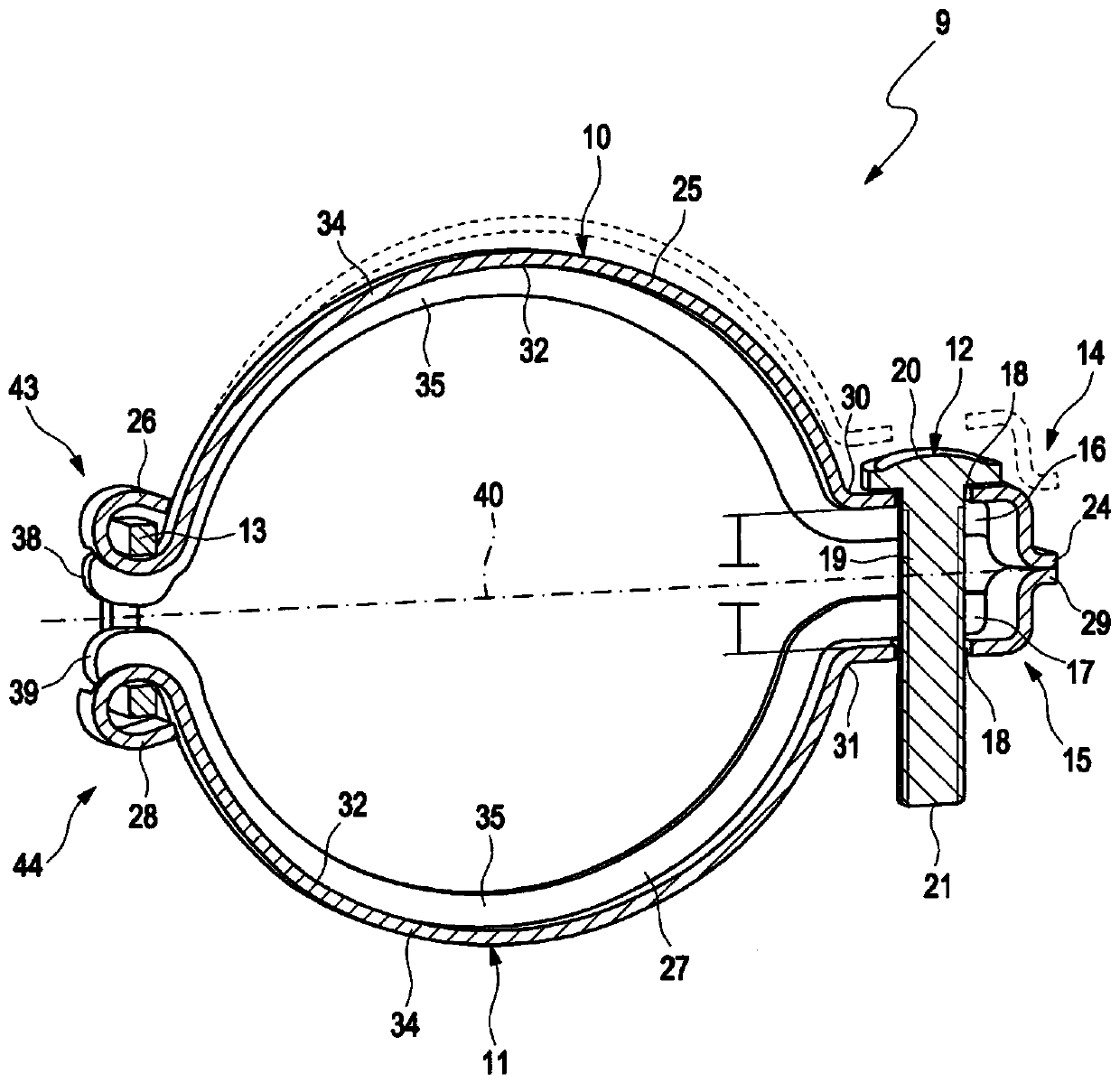

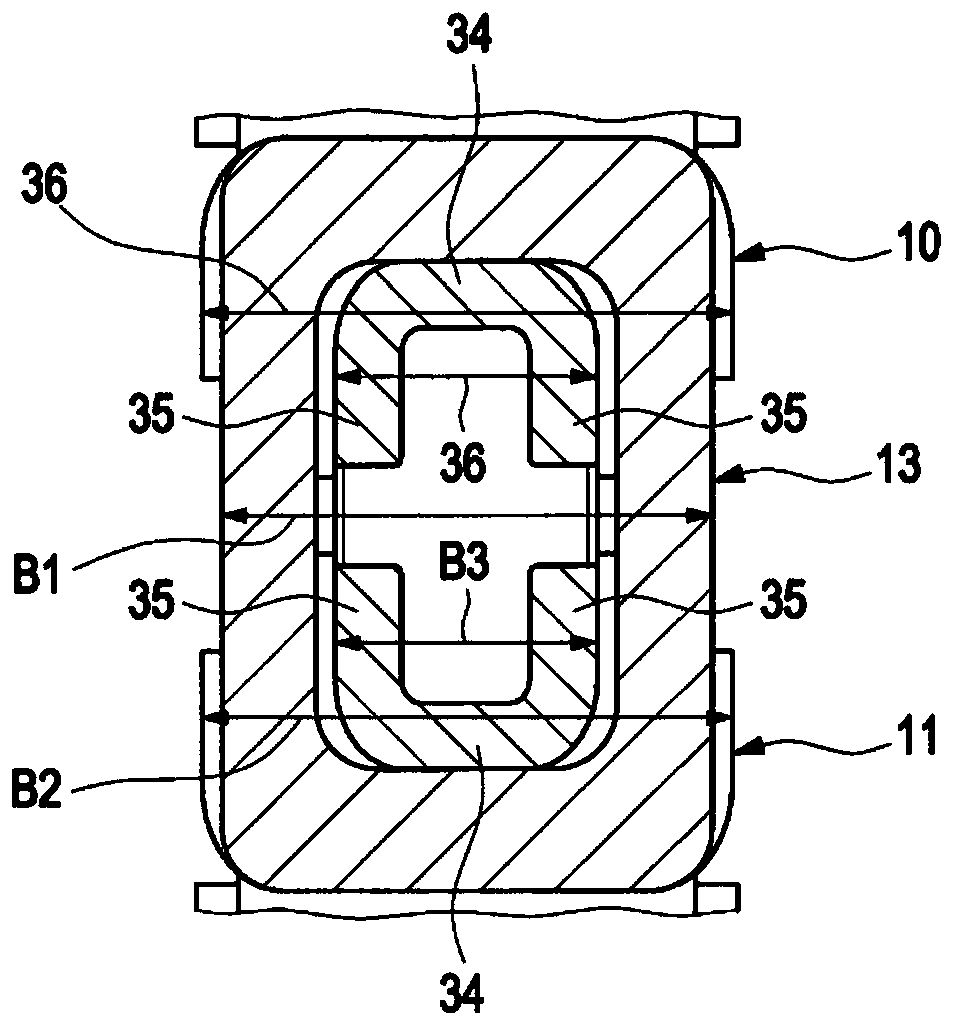

[0028] Exhaust turbocharger 1 in accordance with Figure 6 Constructed in the exemplary embodiment. The exhaust gas turbocharger 1 has a first housing section 2 in the form of a flow-through exhaust gas guide section 2 , which during operation of the exhaust gas turbocharger 1 is supplied by a fluid, usually by exhaust gas. flow through. Usually, but not necessarily, the exhaust gases are combustion products of an internal combustion engine, not shown in detail.

[0029] The exhaust gas turbocharger 1 is equipped with a second housing section 3 which is designed in the form of a bearing section and serves to support a not shown impeller of the exhaust gas turbocharger 1 . The bearing section 3 is located between a flow-through air guide section (not shown in detail) of the exhaust gas turbocharger 1 and the exhaust gas guide section 2 .

[0030] The impeller wheel (not shown in detail) has a compressor wheel (not shown in detail) and a turbine wheel (not shown in detail), w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com