Connection device for exhaust gas turbocharger and exhaust gas turbocharger

A connection device, exhaust gas turbine technology, applied in the direction of gas turbine device, rod connection, exhaust device, etc., can solve the problems of wrong positioning, connection device expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

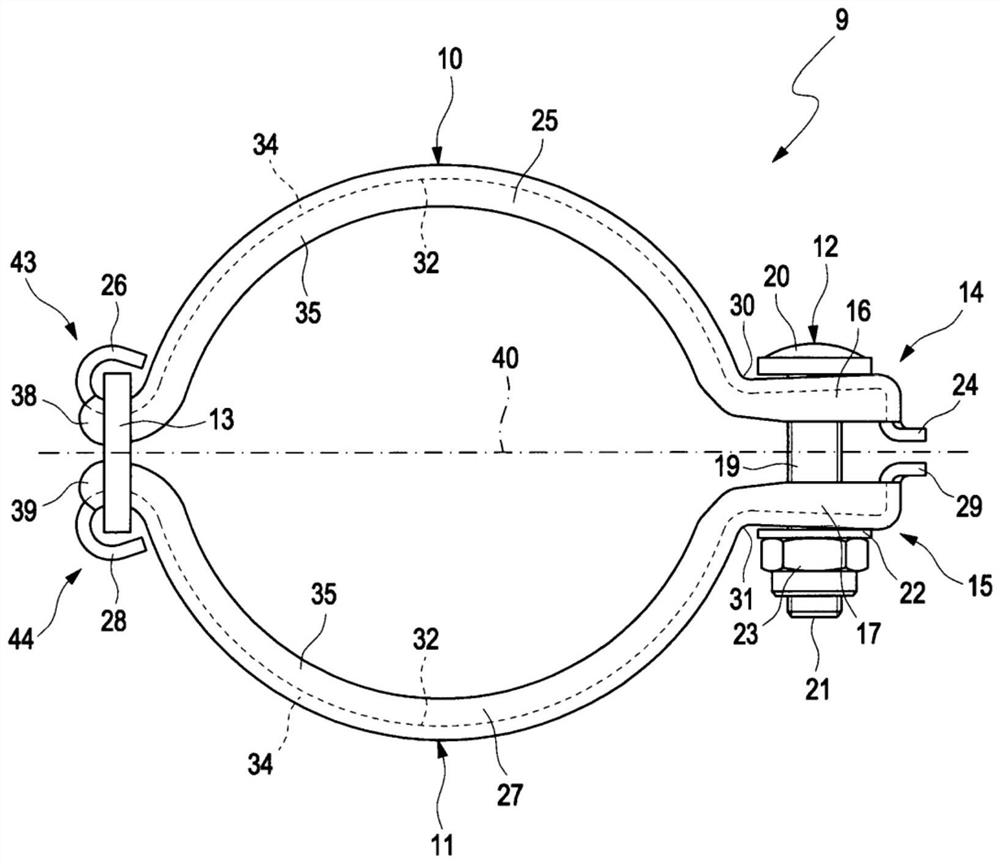

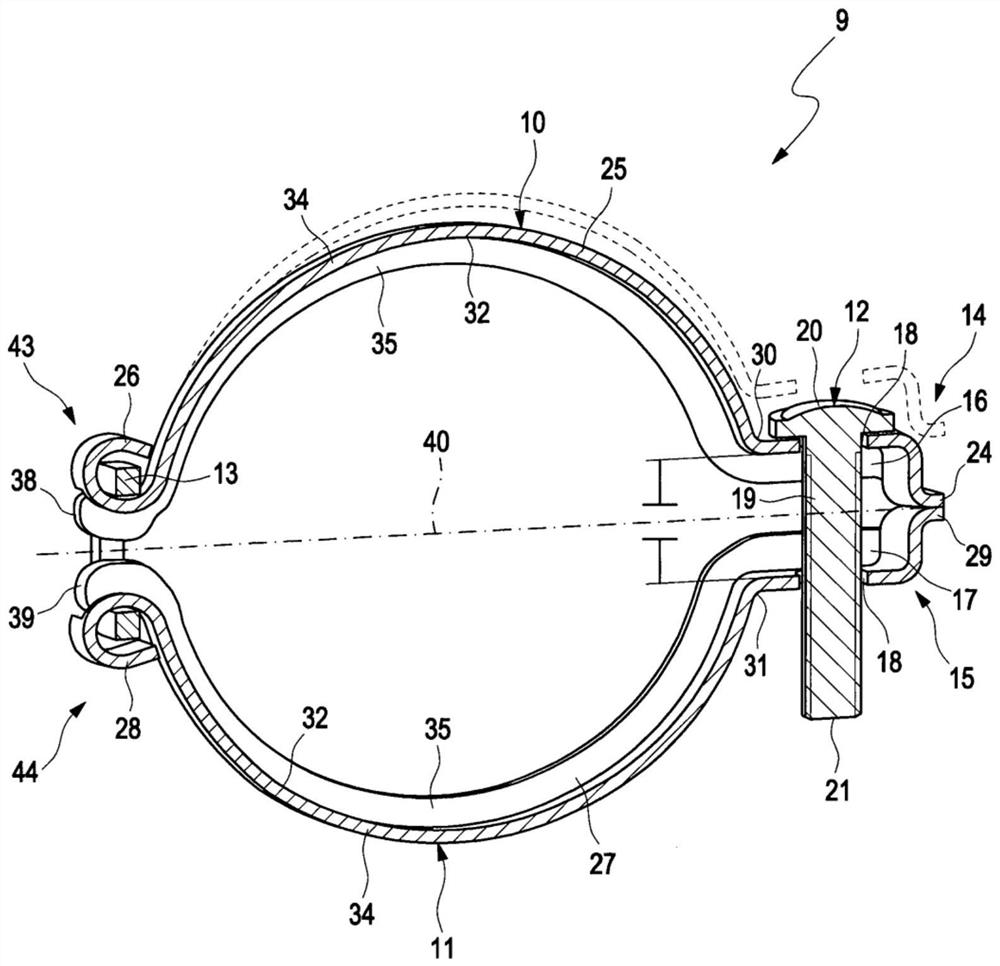

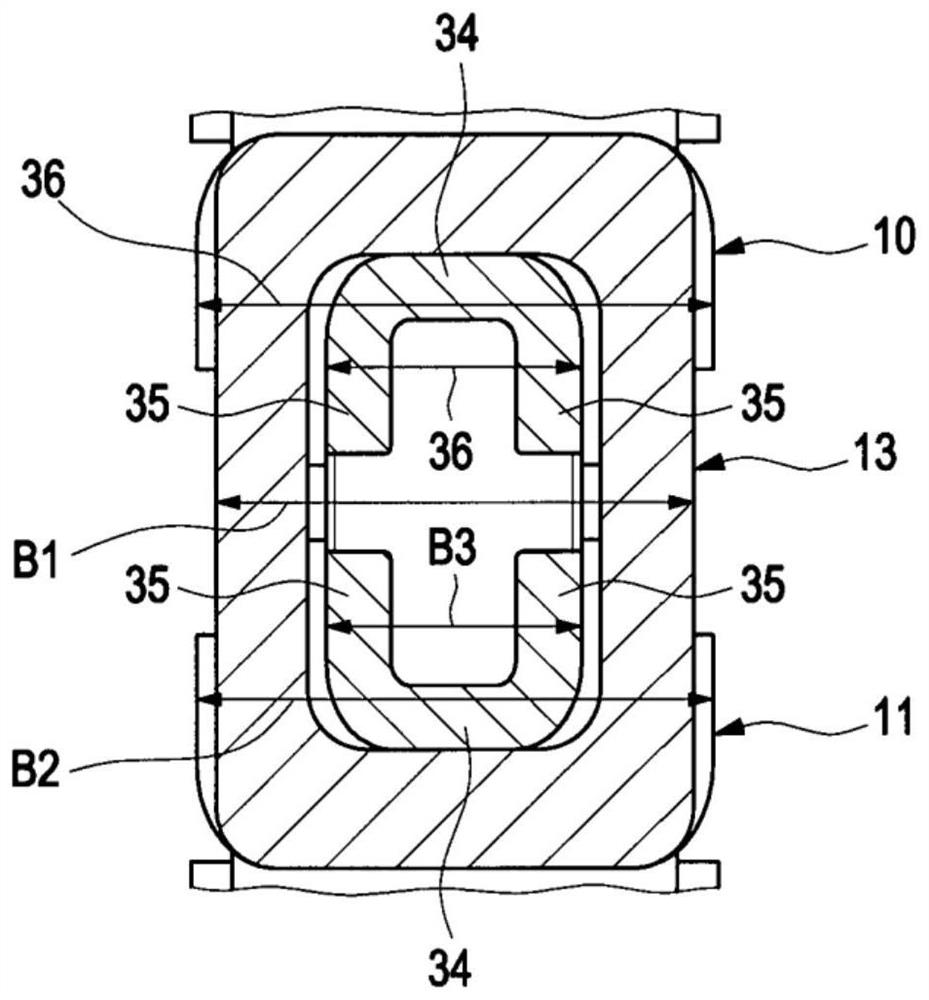

[0028] Exhaust turbocharger 1 in accordance with Image 6 Constructed in the exemplary embodiment. The exhaust gas turbocharger 1 has a first housing section 2 in the form of a flow-through exhaust gas guide section 2 , which during operation of the exhaust gas turbocharger 1 is supplied by a fluid, usually by exhaust gas. flow through. Usually, but not necessarily, the exhaust gases are combustion products of an internal combustion engine, not shown in detail.

[0029] The exhaust gas turbocharger 1 is equipped with a second housing section 3 which is designed in the form of a bearing section and serves to support a not shown impeller of the exhaust gas turbocharger 1 . The bearing section 3 is located between a flow-through air guide section (not shown in detail) of the exhaust gas turbocharger 1 and the exhaust gas guide section 2 .

[0030] The impeller wheel (not shown in detail) has a compressor wheel (not shown in detail) and a turbine wheel (not shown in detail), wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com