High-efficiency scanning spraying method of whole plants of Allium fistulosum

A green onion, high-efficiency technology, applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of poor efficiency, poor control effect, inability to adapt to spraying, etc., to improve the control effect and avoid costs. effect of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

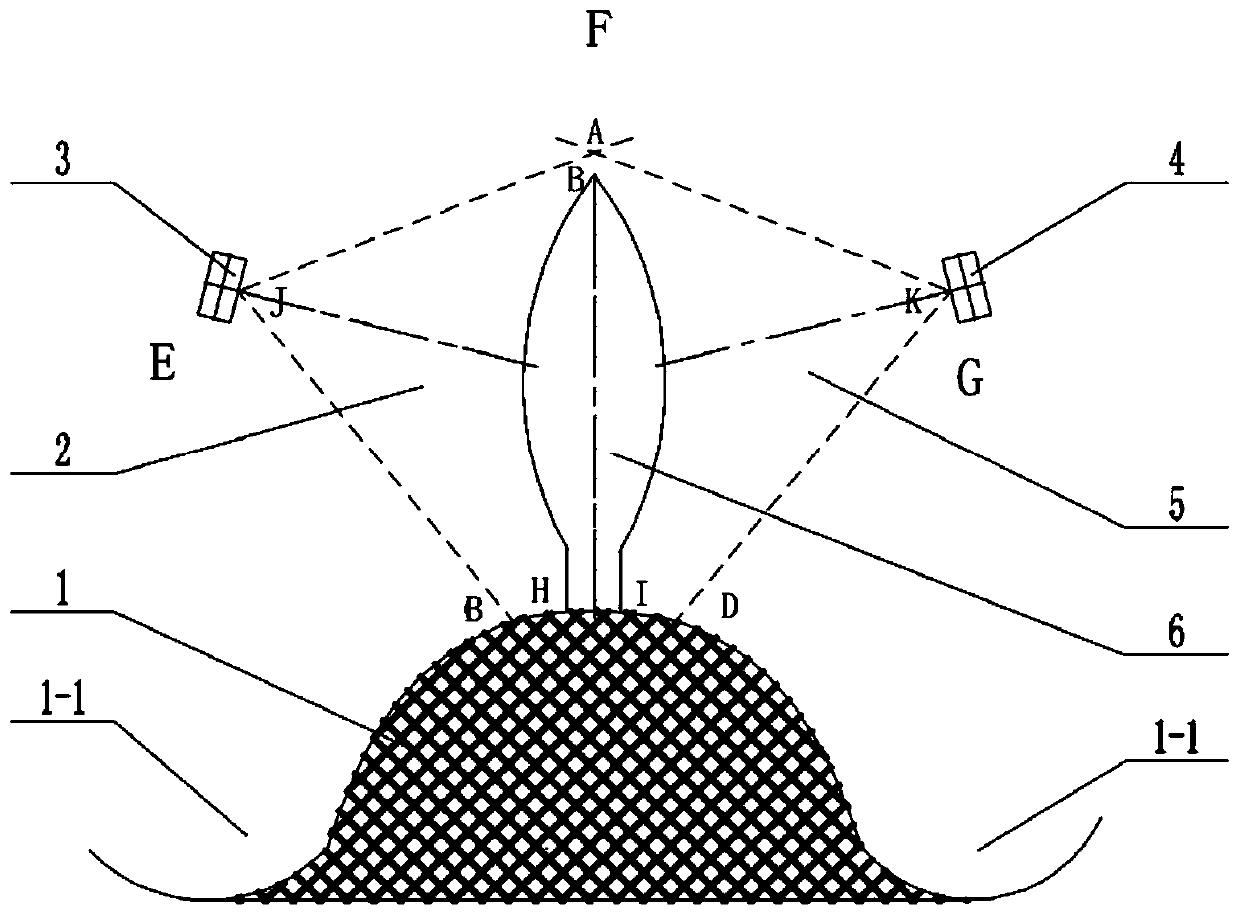

[0023] Attached below Figure 2-7 The present invention is described in detail with this embodiment:

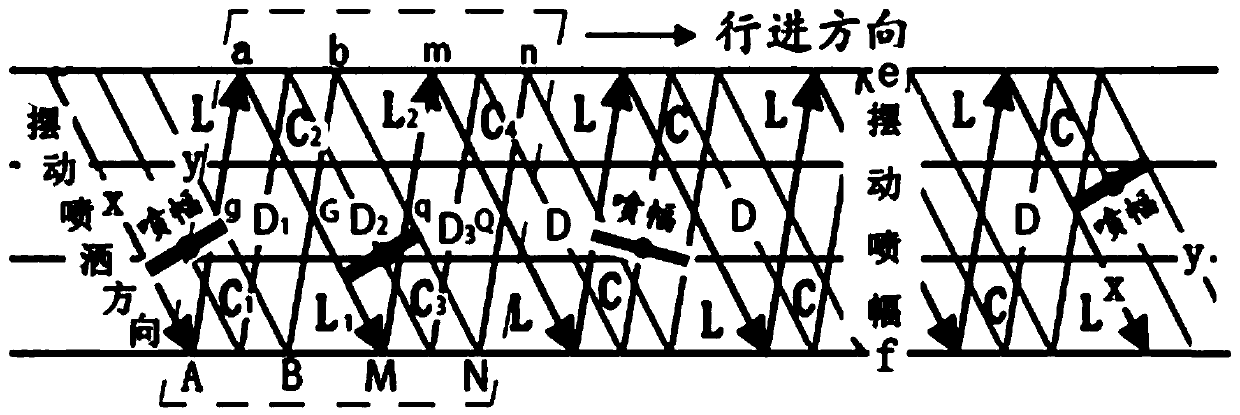

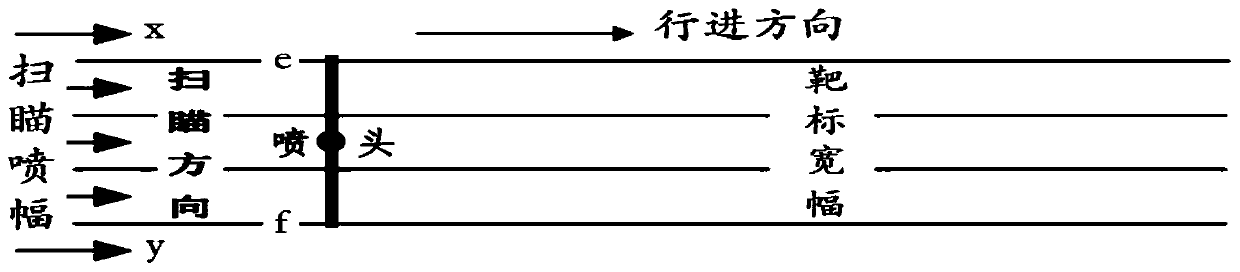

[0024] as attached Figure 2-7 Shown, the working principle of the present invention is that the scanning spraying method that adopts carries out the high-efficiency scanning spraying method of the whole plant of green onion (see figure 2 ), the static spray width xy of the nozzle scanning is greater than the width ef of the target area of a single operation. When spraying, the scanning nozzle can completely cover the crop target without relying on swing to increase the spray width. The movement direction of the nozzle is consistent with the operator's The direction of travel is the same. The one-way movement of the speed of the operator holding the nozzle controls the deposition density and uniformity of the spray droplets sprayed by the nozzle on the target. The trajectory of the nozzle for scanning spraying is straight; and The static spraying width of the conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com