Motor unit and dust collector

A technology for motor units and vacuum cleaners, applied in the installation of vacuum cleaners, electrical equipment, cleaning equipment, etc., can solve problems such as poor layout of motor units, reduce processing costs, simplify fixing methods, and achieve good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

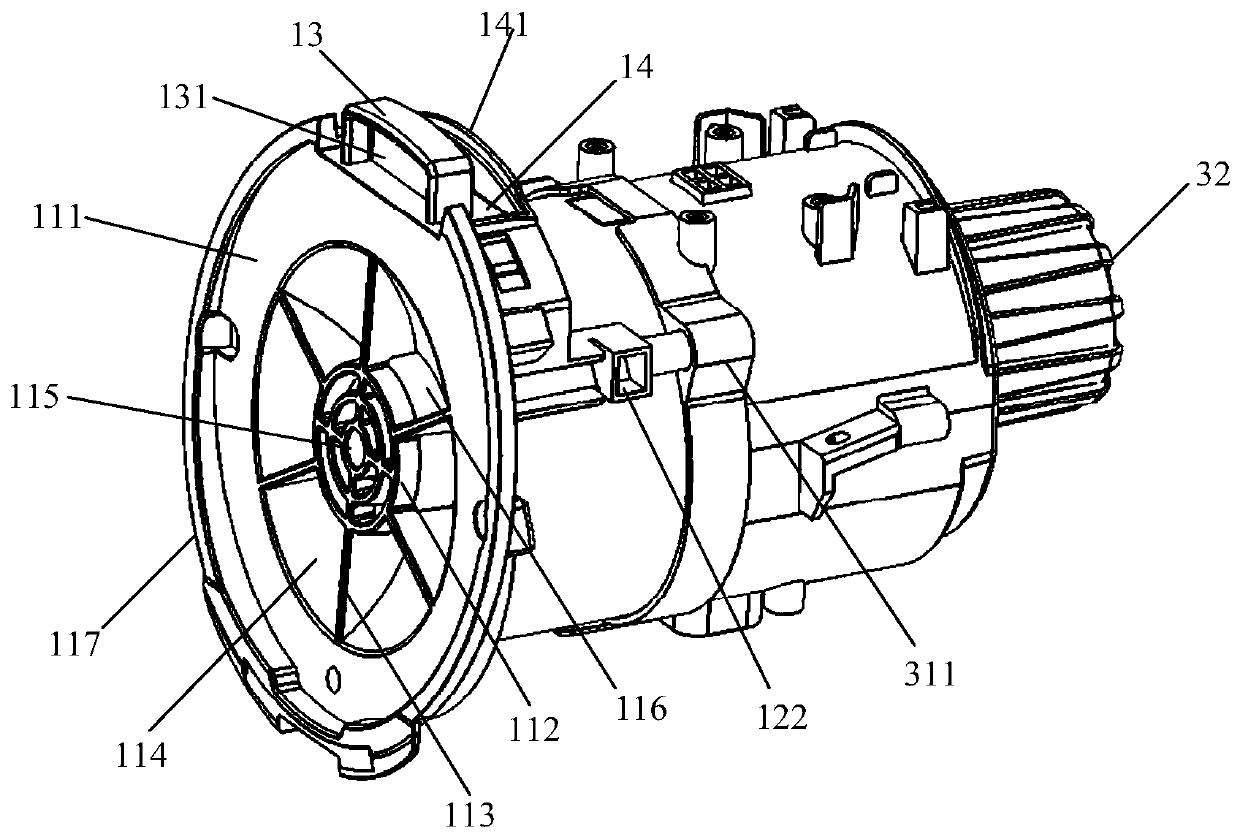

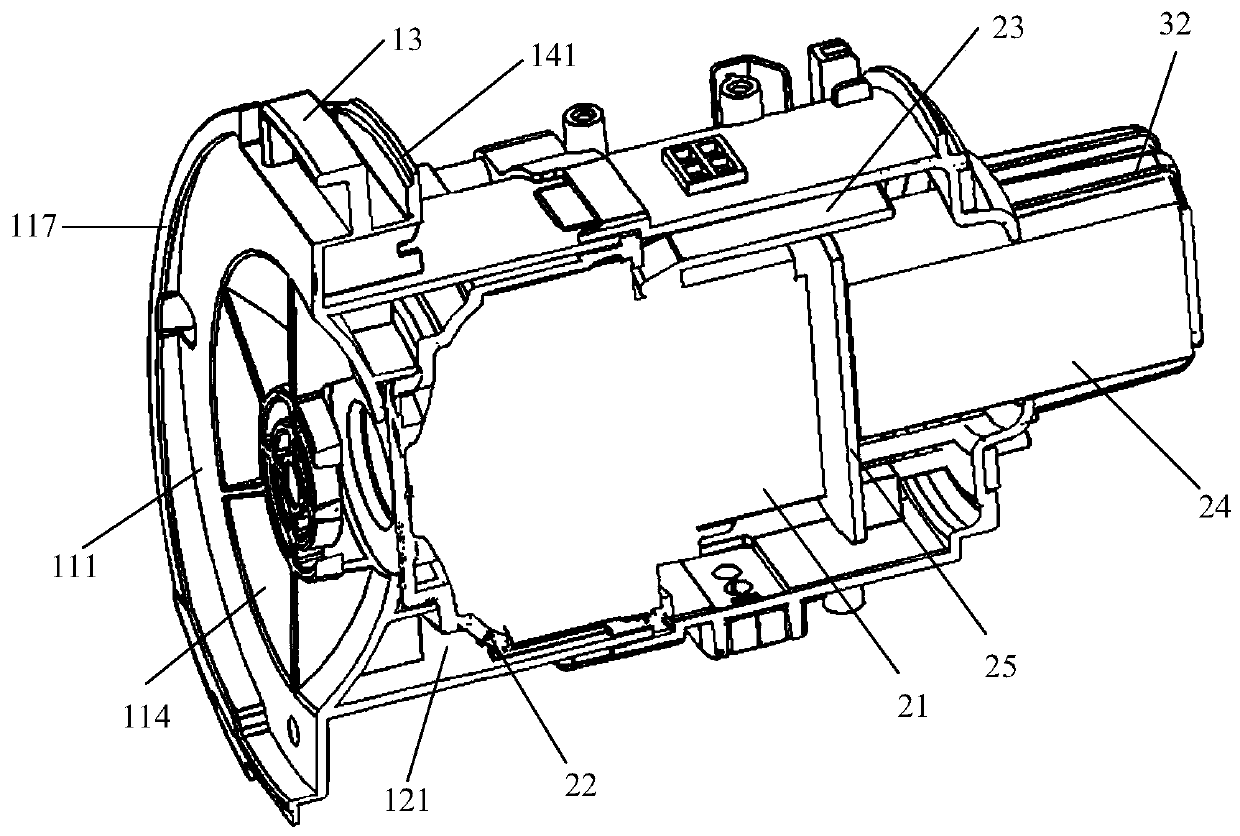

[0056] This embodiment provides a motor unit, such as Figure 1-Figure 4 As shown, it includes a front cover body 1, a motor assembly 2 and a rear cover body 3, and the motor assembly 2 is installed in a motor cover composed of the front cover body 1 and the rear cover body 3.

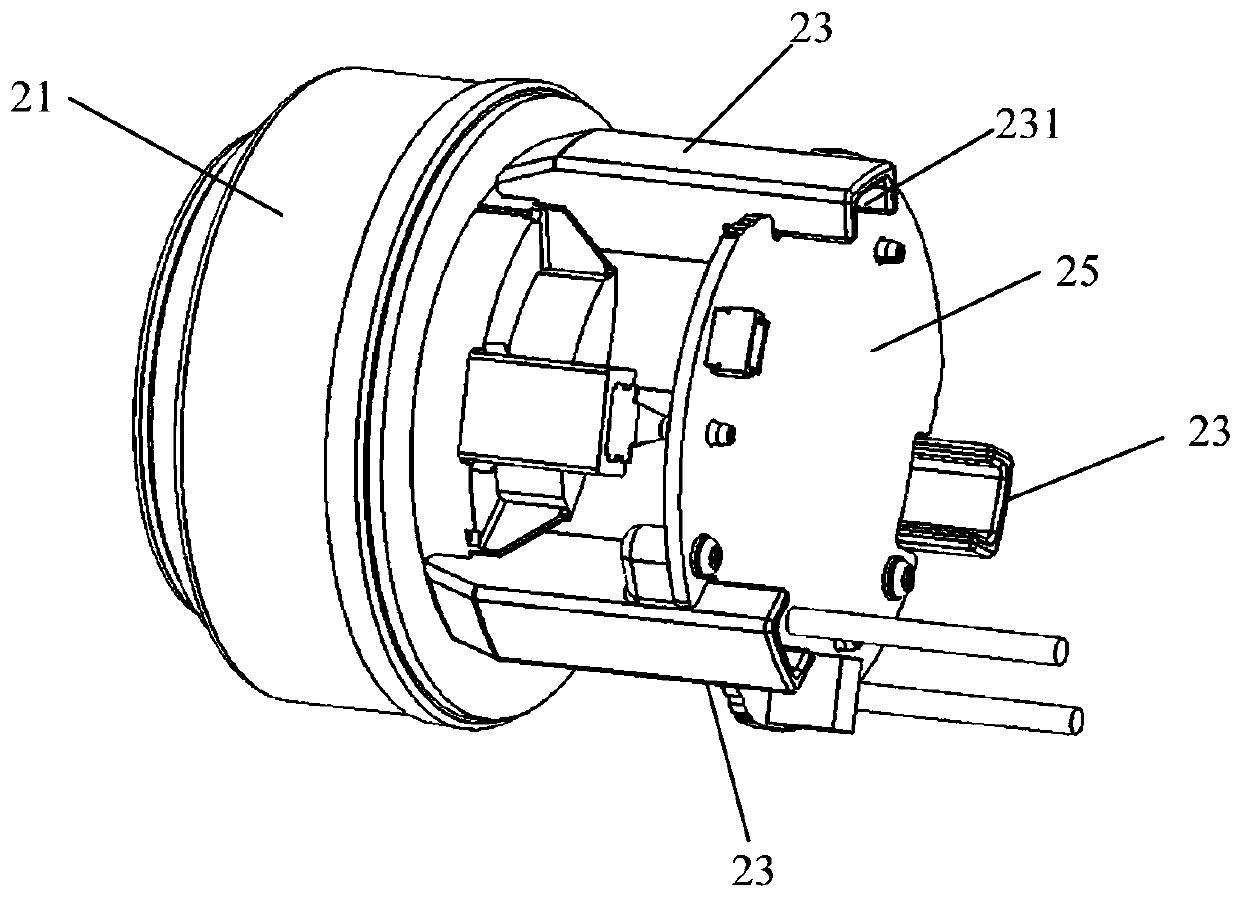

[0057] The motor assembly 2 includes a motor 21, a sealing sleeve 22, a gas guide plate 23, an air outlet filter 24 and a motor control board 25, and the sealing sleeve 22 is wrapped around the intake end of the motor 21; the motor control board 25 is located at the rear end of the motor 21, And be connected with motor 21, to control motor 21 work; The front end of gas guide plate 23 is docked with the gas outlet port of motor 21, and gas guide plate 23 surrounds the outside of air outlet filter 24, to the gas that motor 21 discharges quickly The air outlet filter 24 is guided;

[0058] Compared with the prior art, the motor 21 of this embodiment is clamped in the motor cover through the sealing sleev...

Embodiment 2

[0097] This embodiment provides a vacuum cleaner, such as Figure 5-Figure 10 As shown, it includes the motor unit, the exhaust assembly 4 and the casing 5 provided in the first embodiment.

[0098] The motor unit is installed on the rear end of the housing 5, and the air outlet grid portion 32 of the motor unit passes through the rear end surface of the housing 5, and the exhaust assembly 4 is covered on the air outlet grid portion 32, and is connected with the housing. The rear end surface of 5 is detachably connected, and the gas derived from the air outlet grid part 32 is discharged from the exhaust assembly 4 to the outside of the vacuum cleaner.

[0099] The exhaust assembly 4 includes an exhaust filter 41 and an exhaust hood 42 , and the exhaust hood 42 is provided with an exhaust assembly cavity for assembling the exhaust filter 41 .

[0100] The air exhaust filter 41 is provided with a grid assembly cavity 411 which can accommodate the air outlet grid part 32 , so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com