Convenient-to-clean reaction kettle for zinc sulfate production

A technology of zinc sulfate and reaction kettle, applied in the direction of zinc sulfate, chemical/physical/physical-chemical fixed reactor, cleaning hollow objects, etc., can solve problems such as unfavorable cost, increase water consumption, inconvenience, etc., and achieve convenient slag discharge and discharge, improve the effect of cleaning, improve the effect of the scope of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

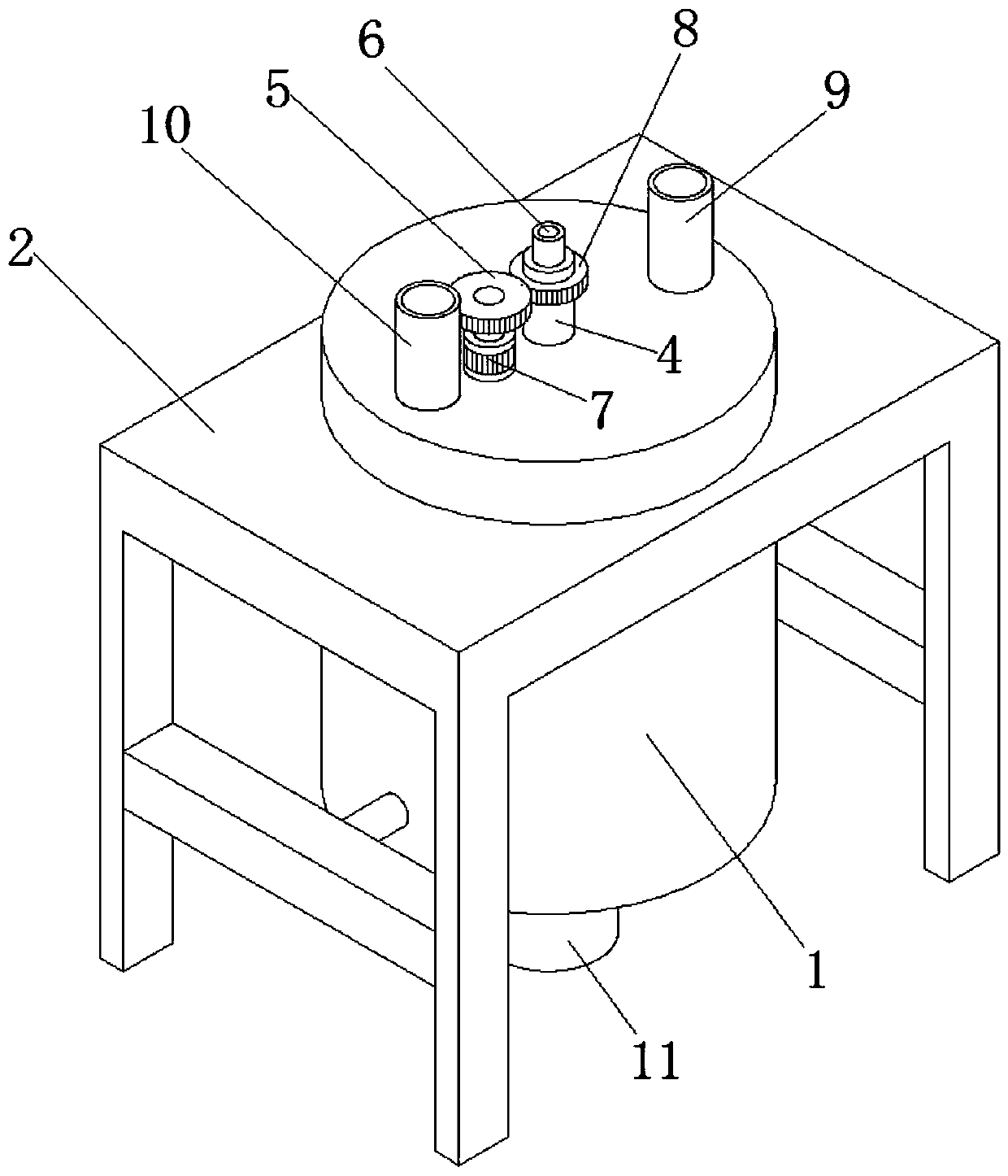

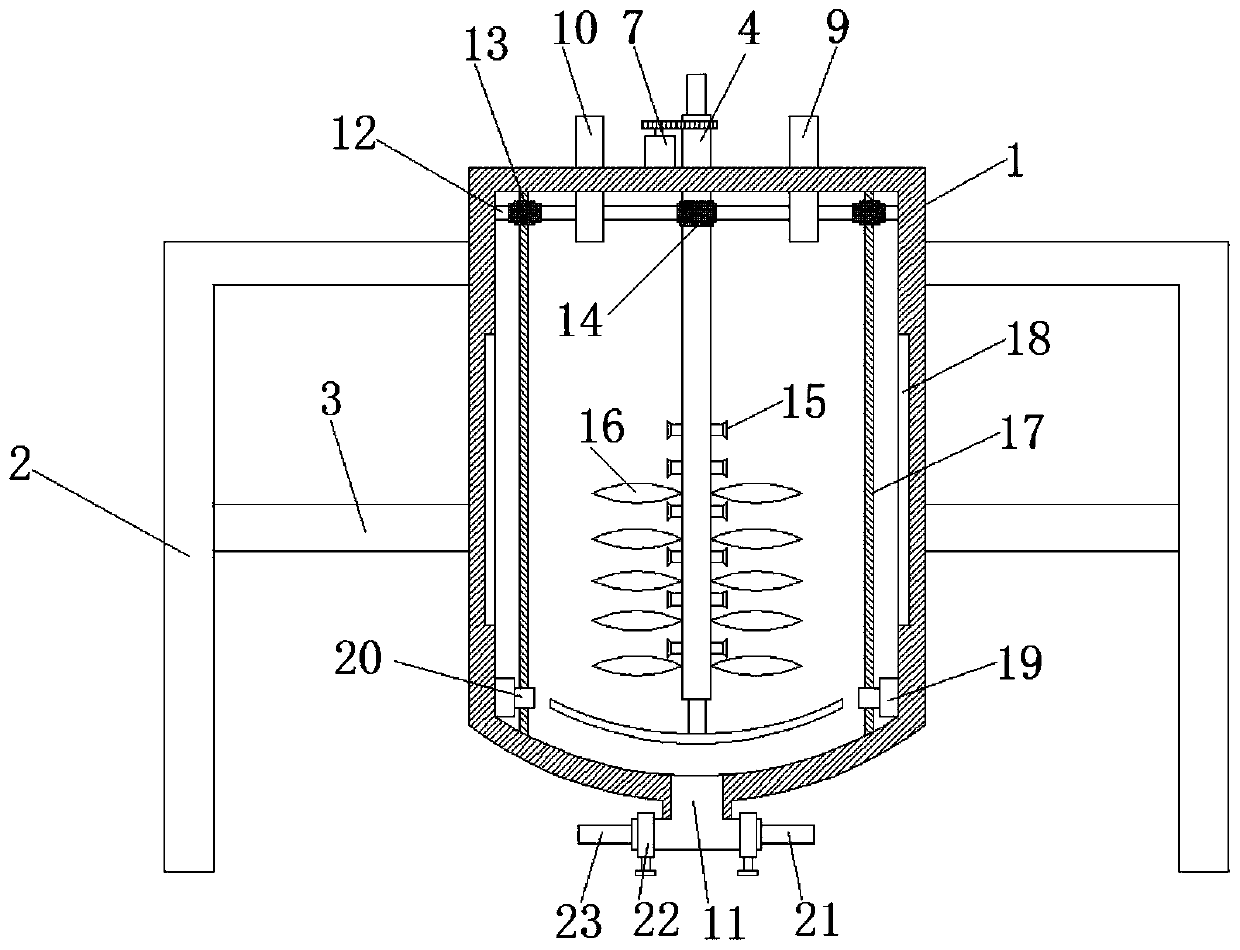

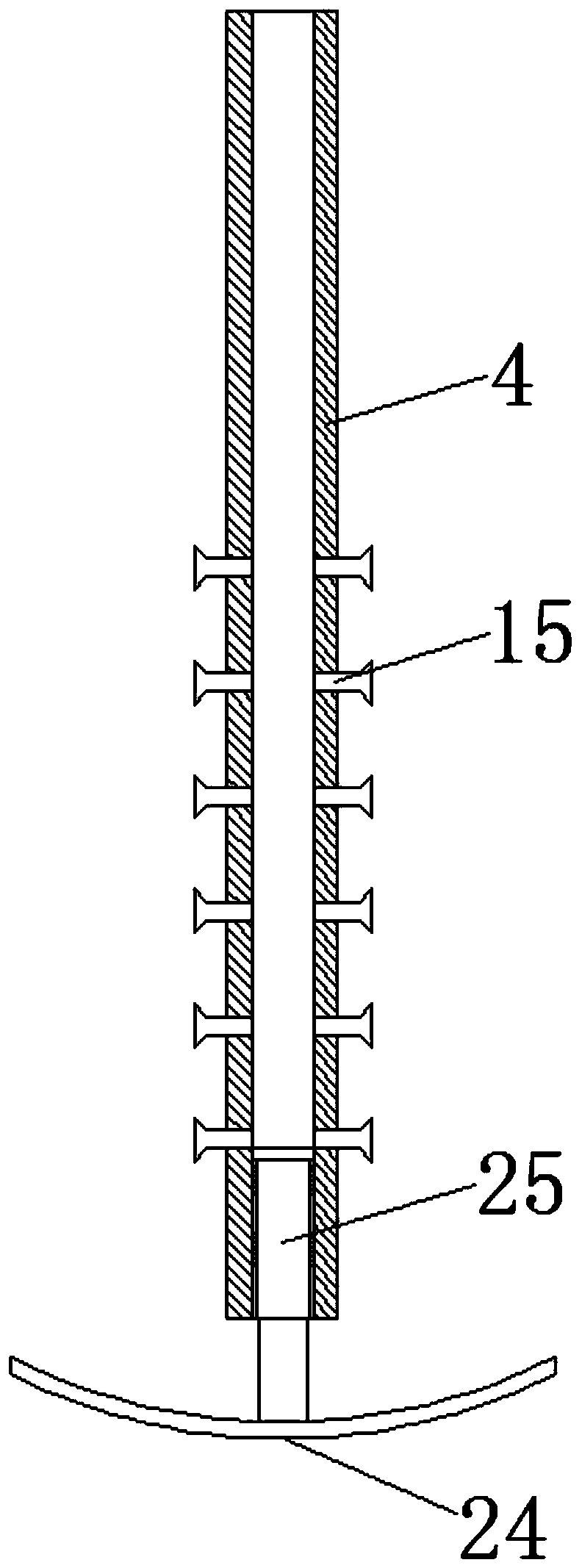

[0023] The present invention provides such Figure 1-4 Shown a kind of reaction kettle that is easy to clean for the production of zinc sulfate, comprises still body 1 and the frame 2 that fixes still body 1, and described still body 1 is fixed on the upper end support plate of frame 2, and the still body 1 The crossbeam between the outer side of the bottom end and the two sets of legs of the frame 2 is fixedly connected by a fixed rod 3. The top of the kettle body 1 is equipped with a feed pipe 9, a feeding pipe 10 and a rotating shaft 4. The bottom end of the kettle body 1 is arc-shaped. Shaped setting, and a discharge port is opened in the middle position, and the discharge pipe 11 is fixedly installed on the discharge port, the rotating shaft 4 is fixedly inserted in the middle position of the kettle body 1 through the bearing, and the bottom end of the rotating shaft 4 is passed through the electric motor. The push rod 25 is connected with a bottom wiping plate 24, and th...

Embodiment 2

[0030] Specifically, two sets of heating plates 18 connected to an external power supply are installed symmetrically on the inner wall of the kettle body 1 , and the heating plates 18 may be conventional PTC heating sheets or adjustable thermostatic tubes.

[0031] Further, the stirring fan blades 16 and the nozzles 15 are arranged in a linear array on both sides of the lower end of the rotating shaft 4, and the nozzles 15 correspond to the stirring fan blades 16 alternately, wherein the inside of the nozzles 15 is also connected to the inner cavity of the rotating shaft 4 Connected, water can enter through the rotating shaft 4 and be sprayed out from the nozzle 15.

Embodiment 3

[0033] Still further, the discharge pipe 11 is a T-shaped pipe, and the top of the T-shaped is fixed and matched in the discharge port, and the two sides of the T-shaped are respectively connected with the slag discharge pipe 23 and the discharge pipe 21, and the T-shaped Valves 22 are installed on both ends, and the corresponding pipelines can be opened by controlling the valve 22 switch.

[0034] On the foregoing basis, the inside of the discharge pipe 11 is also equipped with a filter screen 26 near the inner pipe side communicating with the discharge pipe 21, and the solution discharged from the discharge pipe 21 is filtered to avoid precipitation And the unreacted zinc powder is exposed.

[0035] Concrete, this zinc sulfate production uses the reaction kettle that is easy to clean, and in use, at first dilute sulfuric acid solution is sent in the still body 1 from feeding pipe 8, and zinc powder is sent into still body 1 from feeding pipe 10, At the same time, the water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com