Strip penetrating control method and device

A control method and strip threading technology, which is applied in the direction of rolling force/roll gap control, etc., can solve the problems of reducing production line efficiency, improper operation, and work roll damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

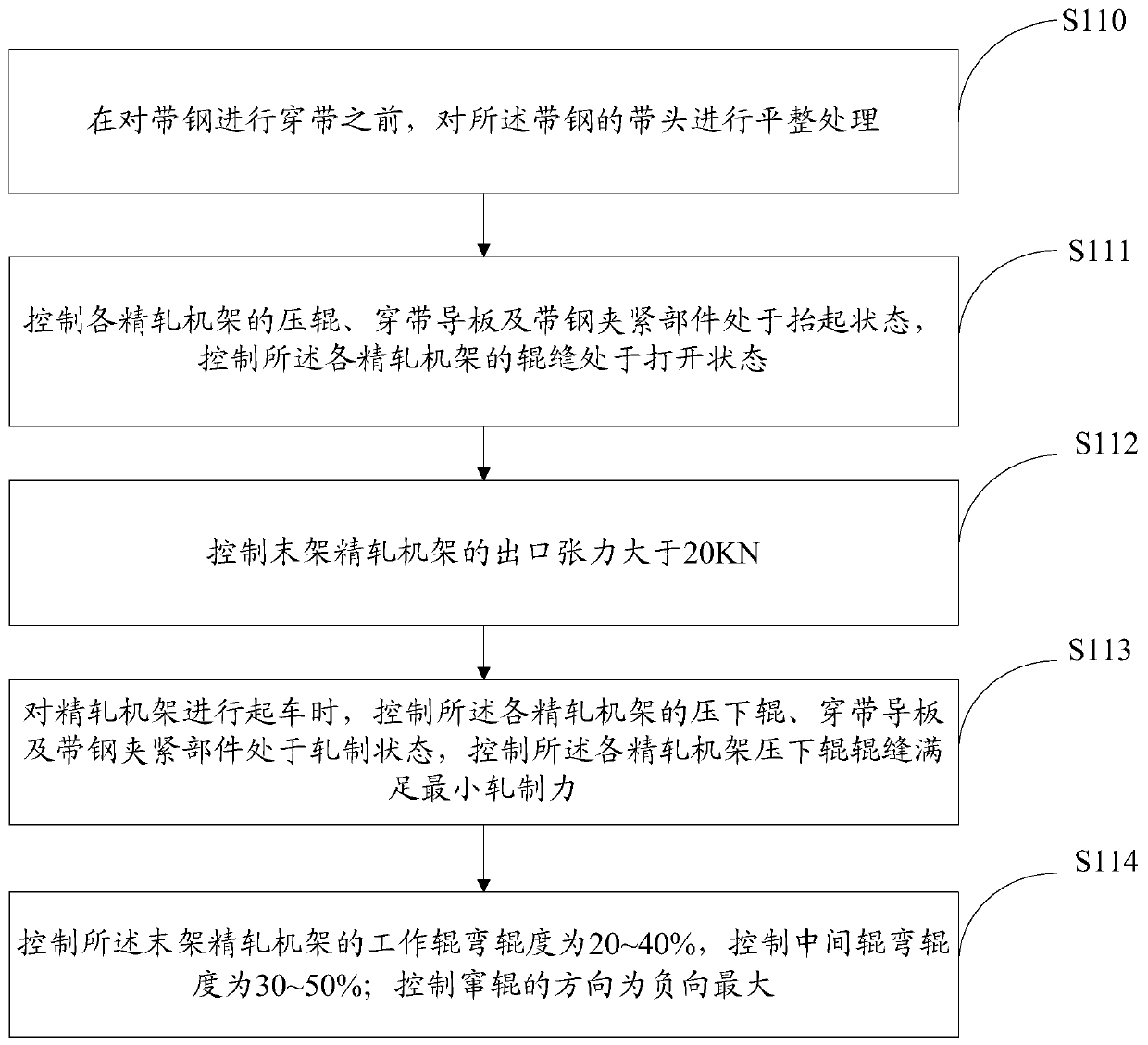

[0036] This embodiment provides a control method for belt-starting, such as figure 1 As shown, the methods include:

[0037] S110, before threading the strip, smoothing the strip head of the strip;

[0038] In order to avoid the belt threading from being affected by the lifting of the belt head, use a leveling tool to smooth the belt head of the strip steel before threading the strip steel; make the belt head meet the following leveling parameters: ~7°, no major deformation within 2-4 meters of the leading edge and relatively flat.

[0039] S112, controlling the pressure rollers, strip threading guide plates and strip clamping components of each finishing stand to be in a lifted state, and controlling the roll gaps of each finishing stand to be in an open state;

[0040] Before threading, control the pressure rollers, threading guide plates and strip clamping parts of each finishing stand to be in a lifted state, and control the roll gaps of each finishing stand to be in an ...

Embodiment 2

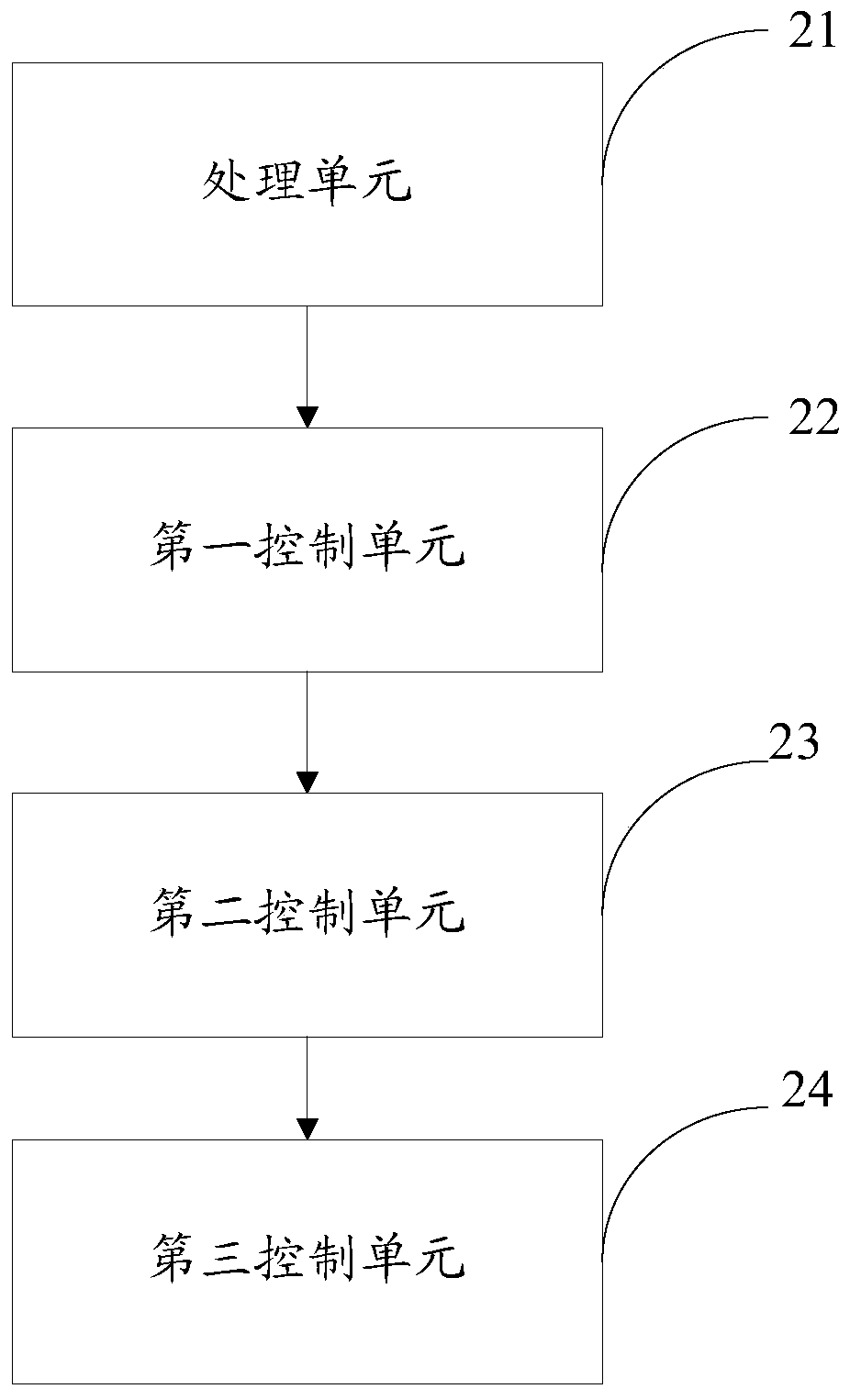

[0054] This embodiment also provides a control device for threading and starting the car, such as figure 2 As shown, the device includes: a processing unit 21, a first control unit 22 and a second control unit 23; wherein,

[0055] In order to avoid the tape head being tilted and affecting the threading, before the strip is threaded, the processing unit 21 is used to use a leveling tool to smooth the strip head of the strip; so that the tape head meets the following leveling parameters: the length of the tape head warping is 10-20mm , The tilt angle is 2-7°, and there is no large deformation within 2-4 meters of the head, which is relatively smooth.

[0056] Before threading, the first control unit 22 is used to control the pressure rollers, threading guide plates and strip clamping parts of each finishing stand to be in a lifted state, and to control the roll gaps of each finishing stand to be in an open state; Place it at the entrance of the first finishing stand and start...

Embodiment 3

[0068] In actual application, when the strip steel with a thickness of 5mm, a width of 1007mm, and a yield strength of 552Mpa is threaded and started, the specific implementation is as follows:

[0069] In order to prevent the tape head from being tilted and affecting the threading of the strip, use a leveling tool to smooth the strip head before threading the strip steel; Large deformation is smoother.

[0070] Before threading, control the pressure rollers, threading guide plates and strip clamping parts of each finishing stand to be in a lifted state, and control the roll gaps of each finishing stand to be in an open state; place the strip head on the first finishing stand The entrance begins to wear the belt. During the threading process, it is necessary to track the threading condition of the tape head so that the threading can be adjusted in time.

[0071] After the strip head comes out of the exit of the last finishing stand, it enters the coiler mandrel and begins to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com