A Double Size Flange Forging Process

A dual-size, flange technology, applied in manufacturing tools, other manufacturing equipment/tools, forming tools, etc., can solve the problems of raw material waste and reduced raw material utilization, and achieve the goal of increasing revenue, improving utilization, and reducing volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

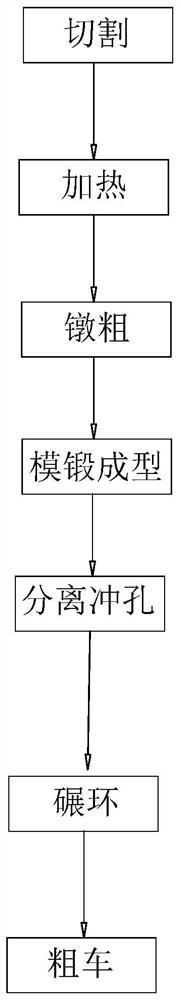

[0033] Embodiment: a kind of double size flange forging process, such as figure 1 shown, including the following steps:

[0034] Step S1: cutting the round steel with a band sawing machine, and cutting the round steel into a plurality of bar blanks. The weight of each billet is 1.10 to 1.15 times the sum of the weights of the two qualified flanges. Through the relationship formula between density and mass, the bar blank of required mass can be cut according to the volume.

[0035] In order to improve the strength of the produced flange, the round steel is made of steel slag ingot remelted in the electroslag furnace. The steel ingot undergoes electroslag remelting to purify the metal and obtain an electroslag ingot with uniform and dense clean structure. The steel remelted by electroslag has high purity, low sulfur content, less non-metallic inclusions, smooth surface of steel ingot, clean and uniform compact, uniform metallographic structure and chemical composition, so the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com