Clamping and positioning device for cutting metallographic sample and clamping and positioning method thereof

A technology for clamping and positioning metallographic samples, which is applied in the direction of positioning devices, sampling devices, and preparation of test samples. Effective clamping and fixing to improve cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

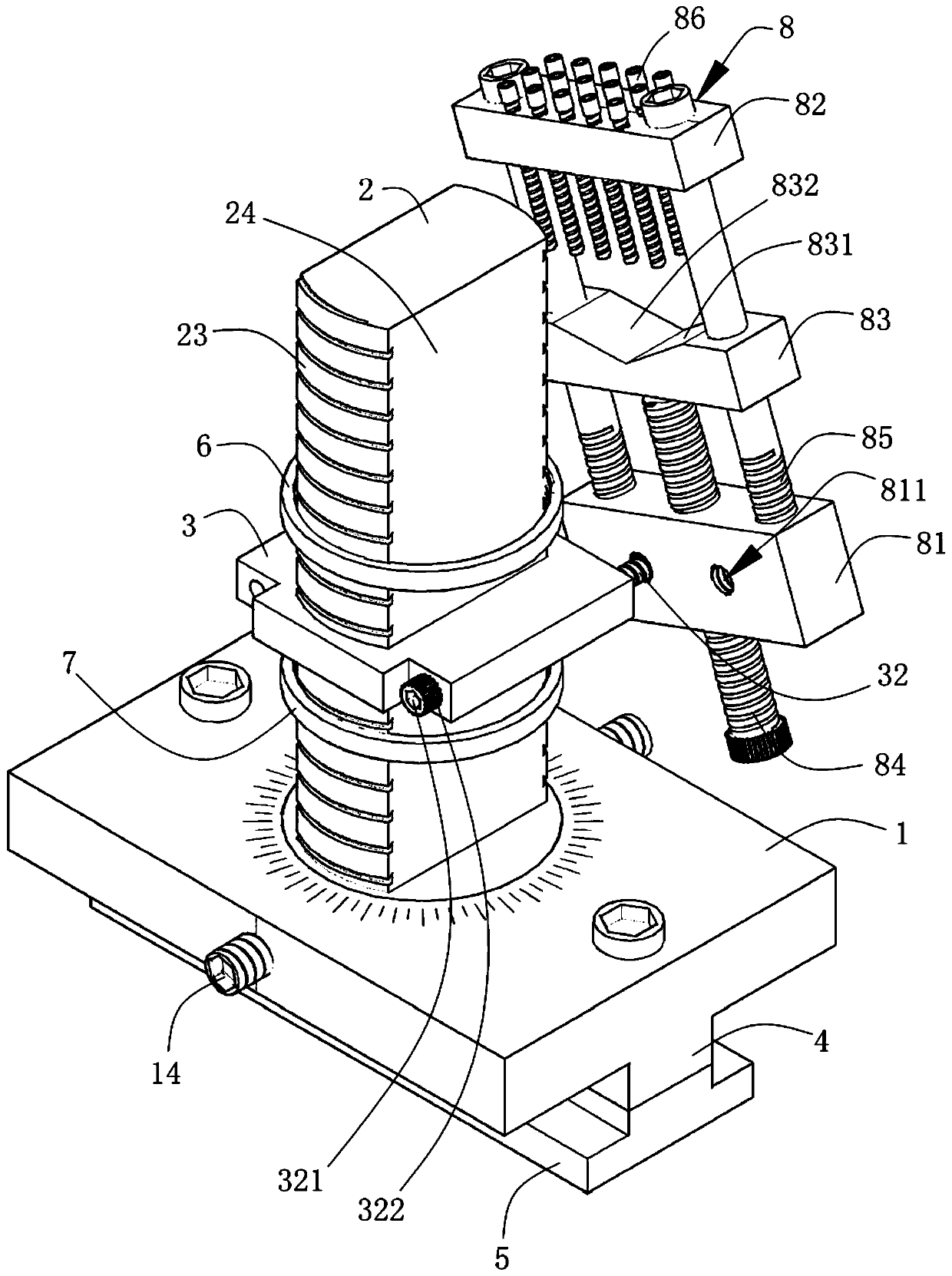

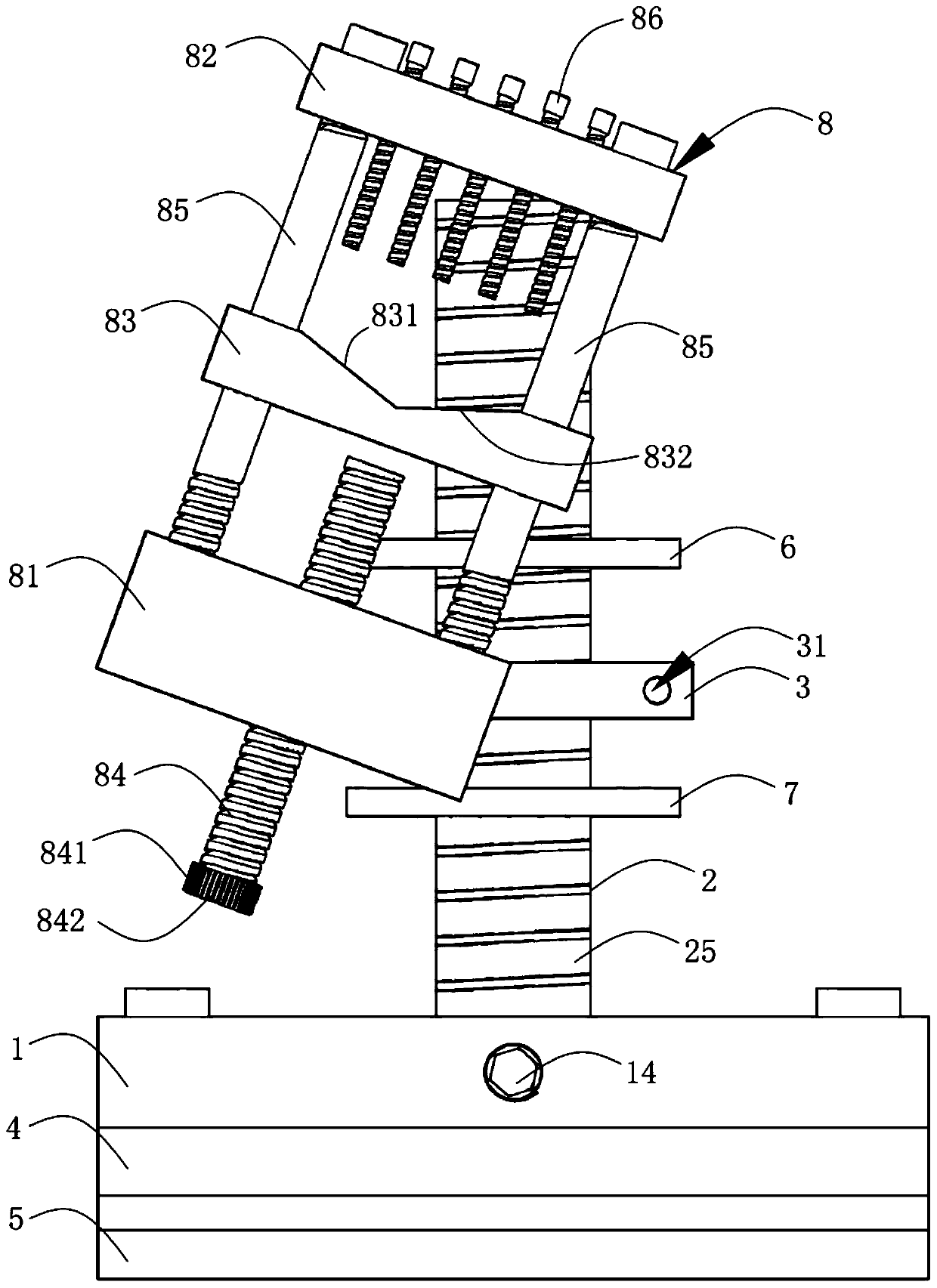

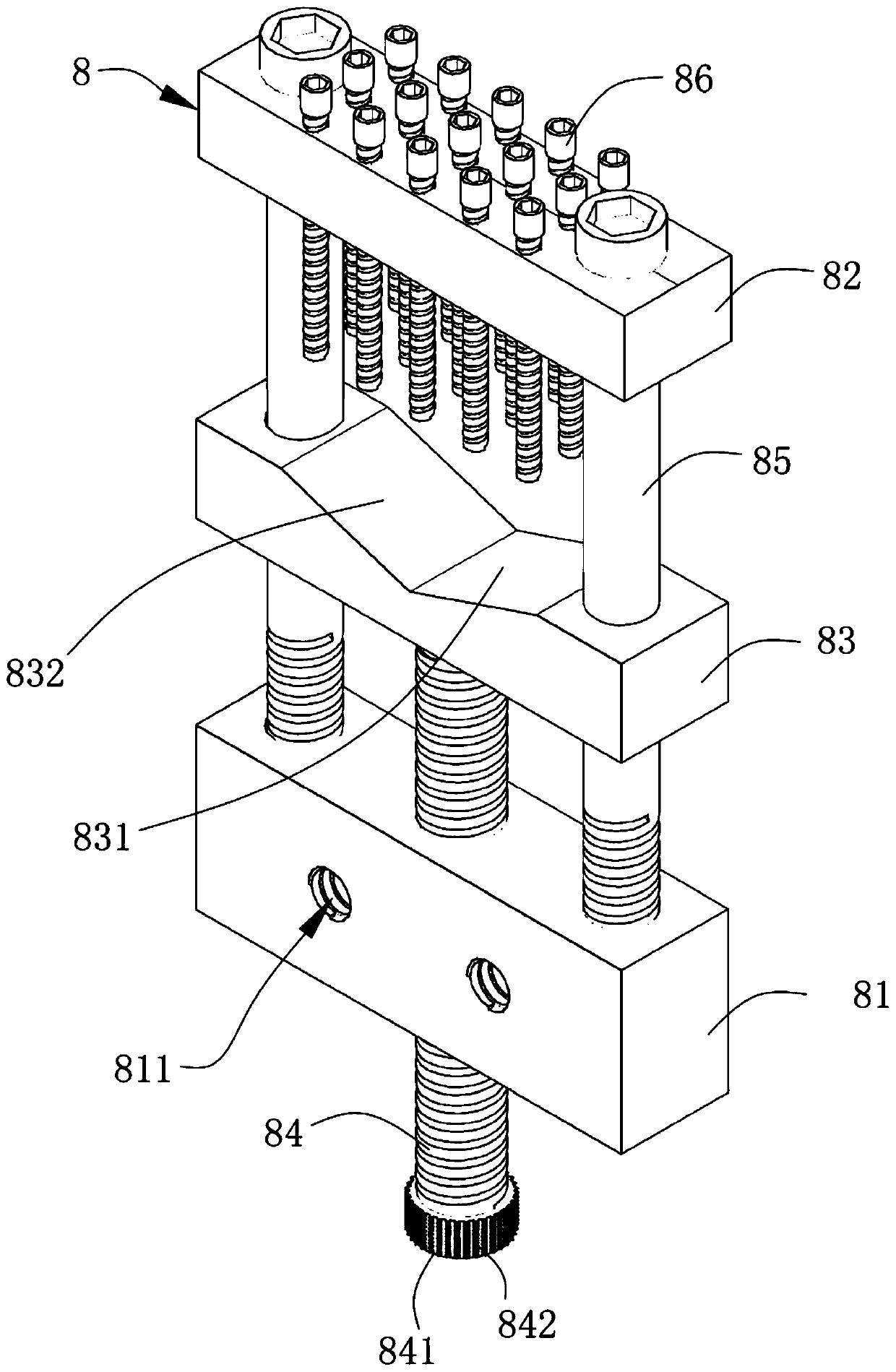

[0031] Such as Figure 1 to Figure 7 As shown, the present invention provides a clamping and positioning device for cutting metallographic samples, which includes a bracket mechanism and a clamp mechanism 8 that is movably installed on the bracket mechanism. The bracket 2 of the base 1, the sliding sleeve 3 moving along the length direction of the bracket 2, the sliding sleeve adjusting and locking assembly for positioning the sliding sleeve 3 on the bracket 2, the slider 4 designed integrally with the bracket base 1 and installed on The locking base 5 of the slider 4; the clamp mechanism 8 includes a supporting block 81, an upper clamping block 82, a lower clamping block 83, a top tightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com