Chain track device capable of automatically adjusting width of chain tracks

A chain rail device and chain rail technology, applied in the field of plastic molding equipment, can solve the problems affecting the quality of molded plastic products, the sheet is not flat enough, and the thickness is uneven, so as to achieve accurate adjustment of displacement, uniform thickness, and improve molding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

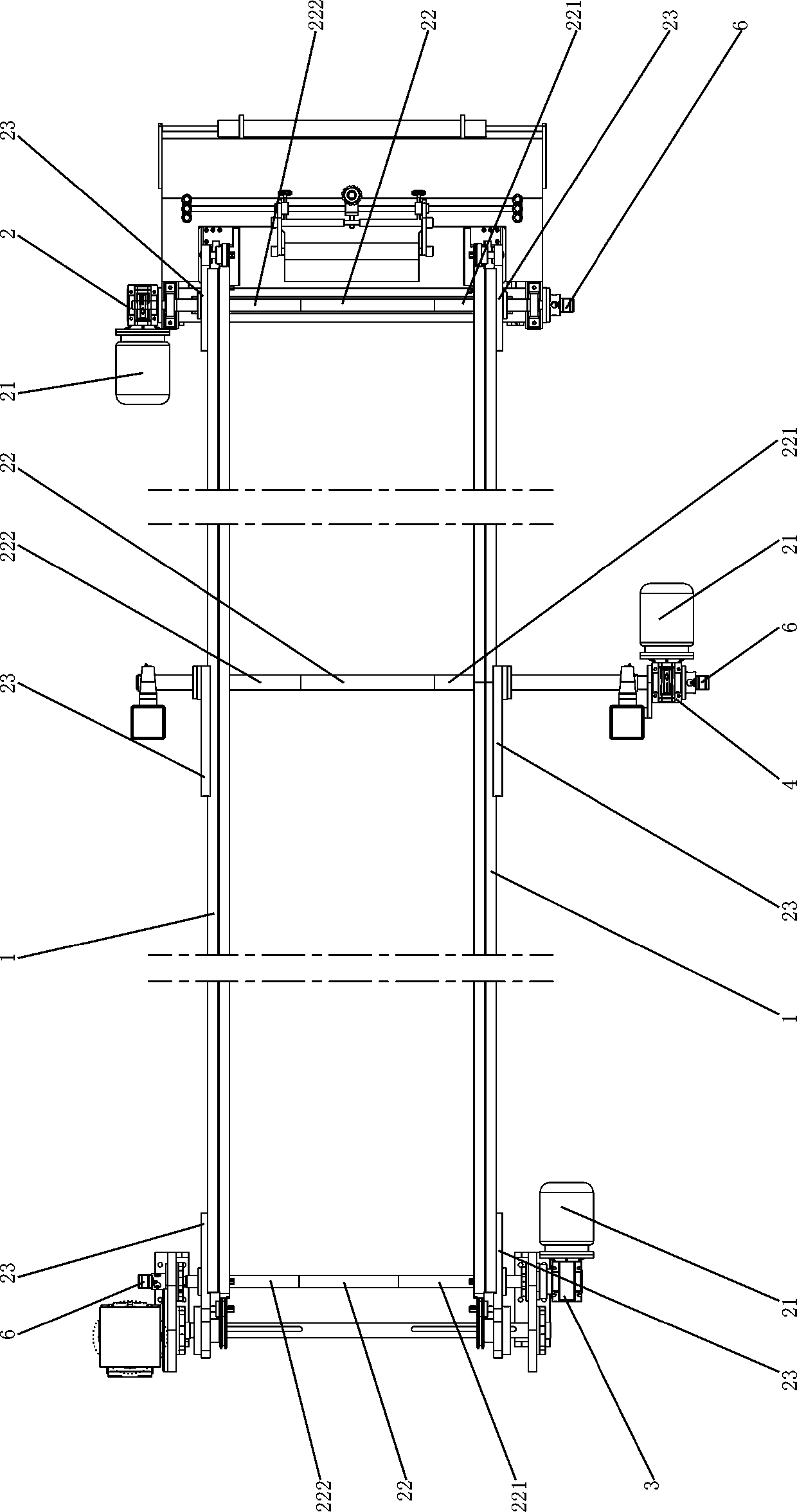

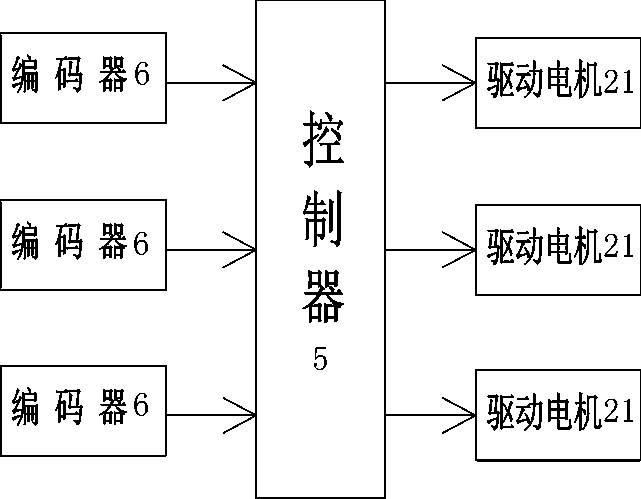

[0014] like figure 1 , figure 2 As shown, the chain rail device capable of automatically adjusting the width of the chain rail includes a frame (not shown in the figure), two chain rails 1, a front end width adjustment assembly 2, a rear end width adjustment assembly 3, and a middle width adjustment assembly. Component 4, controller 5 and multiple encoders 6, two chain rails 1 are arranged side by side and along the front and rear directions, the front end width adjustment assembly 2 and the rear end width adjustment assembly 3 are respectively arranged on the two chain rails 1 The front end, the rear end, and the middle width adjustment assembly 4 are arranged in the middle of the two chain rails 1, and the front end width adjustment assembly 2, the rear end width adjustment assembly 3 and the middle width adjustment assembly 4 all include a drive motor 21, an adjustment screw 22 and two translation bases 23, the driving motor 21 is installed on the frame, the adjusting scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com