Axial flow compressor stationary blade adjusting mechanism and axial flow compressor applying same

A technology of axial flow compressor and adjustment mechanism, which is applied in the field of axial flow compressors, can solve the problems of limited adjustment speed, unfavorable compressor quick adjustment response, difficulty in realizing fast adjustment of stator vane angle, etc., and achieve the effect of improving the adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the purpose, structure and function of the present invention, the stator vane adjustment mechanism of the axial flow compressor of the present invention and the axial flow compressor applying it will be further described in detail below in conjunction with the accompanying drawings.

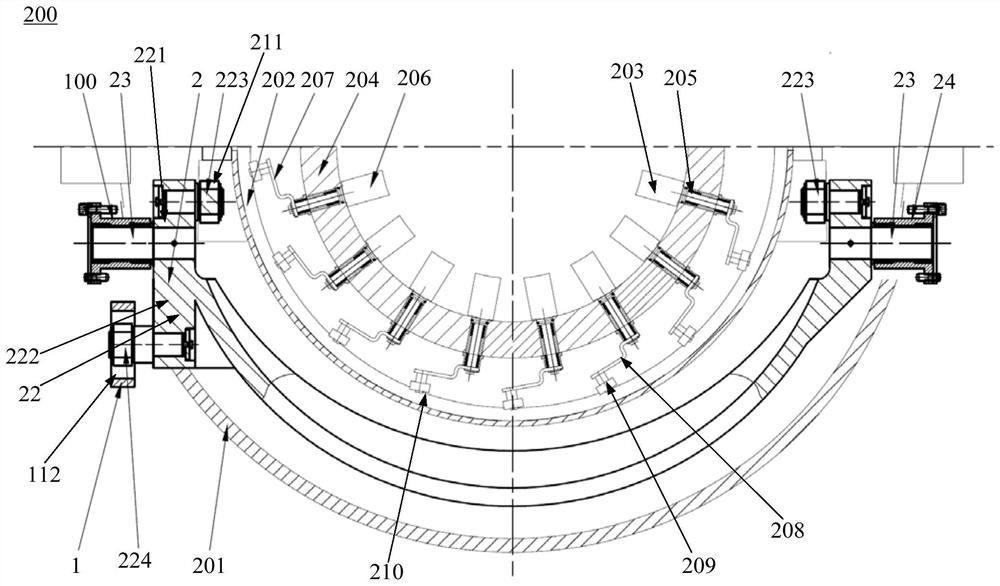

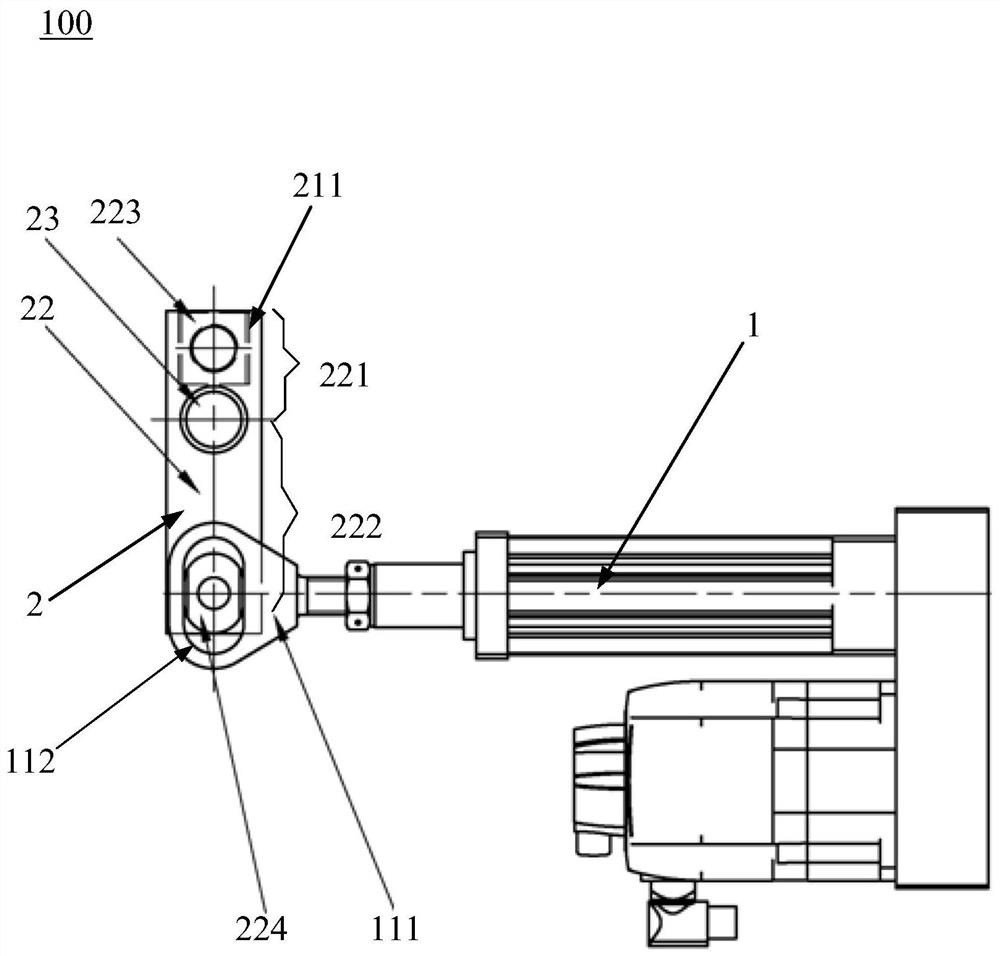

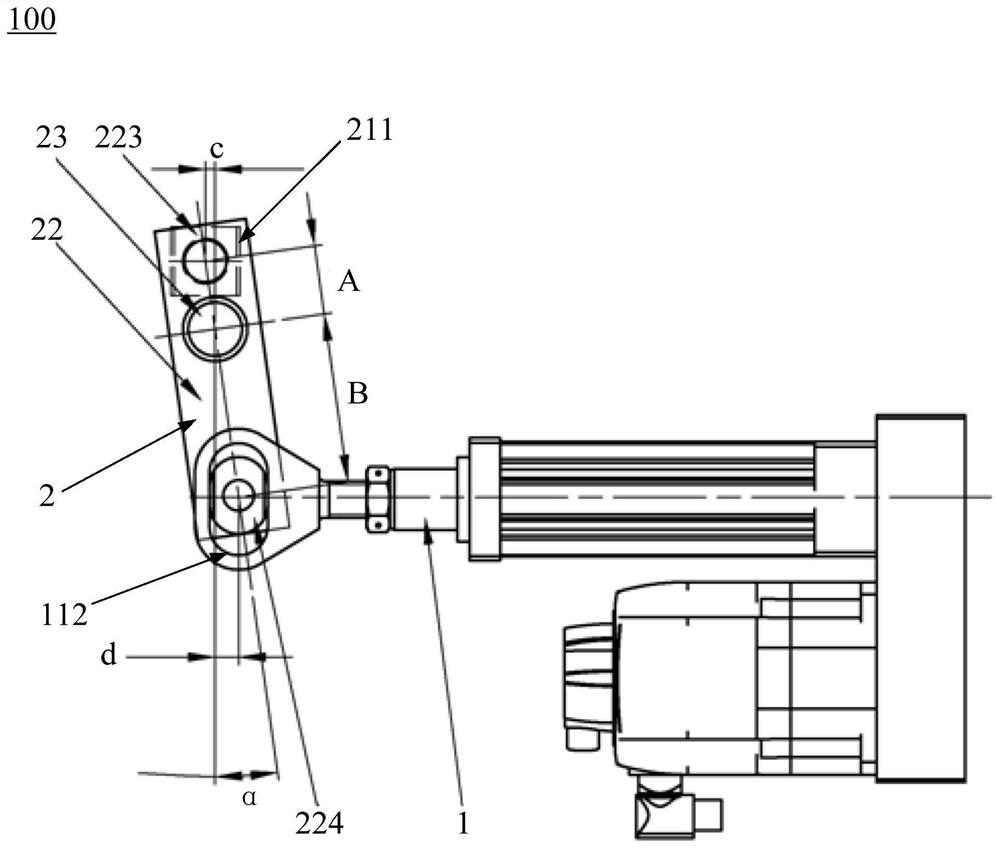

[0026] Figure 1 to Figure 3 The structure of the vane adjustment mechanism 100 of the axial flow compressor according to the embodiment of the present invention is shown. The stator vane adjustment mechanism 100 of the axial flow compressor includes: an actuator 1, a linkage half-ring assembly 2, the linkage half-ring assembly 2 includes a positioning shaft 23 and a linkage half-ring 22 capable of rotating around the positioning shaft 23, the linkage half-ring 22 includes The first linkage arm 221 and the second linkage arm 222 located on both sides of the positioning shaft 23, the first linkage arm 221 is used to connect with the adjustment cylinder 202 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com