An anti-scratch spreader for panels

An anti-scratch and spreader technology, which is applied in the field of transport spreaders, can solve the problems of unprotected plate surfaces and lifting, so as to save the time of disassembly and installation, reduce crushing injuries, improve production efficiency and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

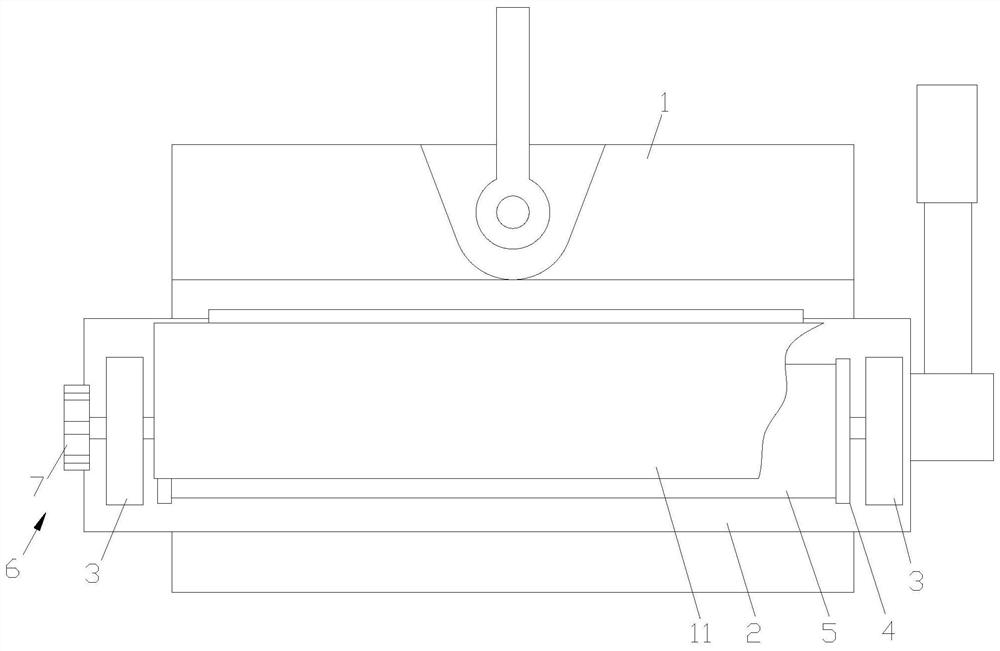

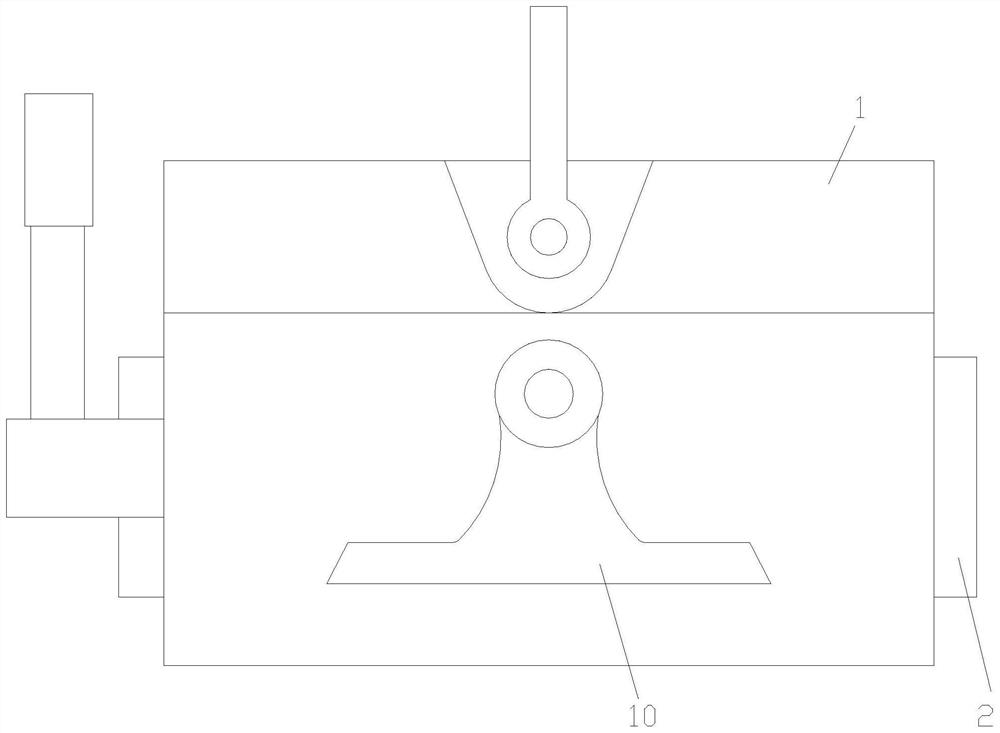

Embodiment 1

[0024] Embodiment 1 of the present invention: a kind of anti-scratch spreader for plate, constituted as figure 1 and image 3 As shown, it includes a permanent magnet lifter 1, a mounting plate 2, a support plate 3 and a hollow cylinder 4, the surface of the hollow cylinder 4 is wound with an interlayer 5, and the mounting plate 2 is fixedly connected to the permanent magnet lifter 1. On the side, the mounting plate 2 is provided with two parallel support plates 3, the support plate 3 is detachably connected with a suspension 6, and the hollow drum 4 is rotatably arranged on the suspension 6. The side of the lifter 1 is provided with an interlayer 5 that can be taken as needed, so that the permanent magnet lifter 1 can reduce the crushing of the smooth plate when lifting the smooth plate, which is conducive to improving production efficiency and Quality, when there are hard objects such as chips on the smooth plate, the interlayer 5 will play a better role in buffering and pr...

Embodiment 2

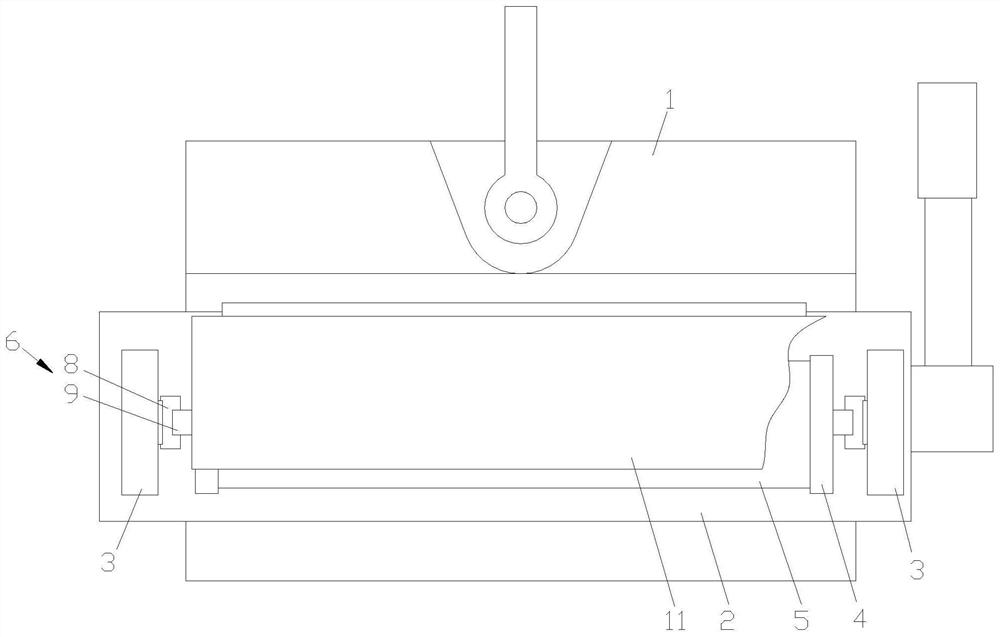

[0030] Embodiment 2: An anti-scratch spreader for panels, constituted as figure 2 and image 3 As shown, it includes a permanent magnet lifter 1, a mounting plate 2, a support plate 3 and a hollow cylinder 4, the surface of the hollow cylinder 4 is wound with an interlayer 5, and the mounting plate 2 is fixedly connected to the permanent magnet lifter 1. On the side, the mounting plate 2 is provided with two parallel support plates 3, the support plate 3 is detachably connected with a suspension 6, and the hollow drum 4 is rotatably arranged on the suspension 6. The side of the lifter 1 is provided with an interlayer 5 that can be taken as needed, so that the permanent magnet lifter 1 can reduce the crushing of the smooth plate when lifting the smooth plate, which is conducive to improving production efficiency and quality.

[0031] The mounting plate 2, the support plate 3 and the hollow cylinder 4 are all light materials, such as plastic, so when the mounting plate 2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com