Energy-saving chemical fiber silk cutting machine

A silk cutting machine, energy-saving technology, applied in fiber processing, fiber cutting, textiles and papermaking, etc., can solve the problems of cutting failure, chemical fiber tow fixation, and easy deviation of cutting knives, etc., and achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

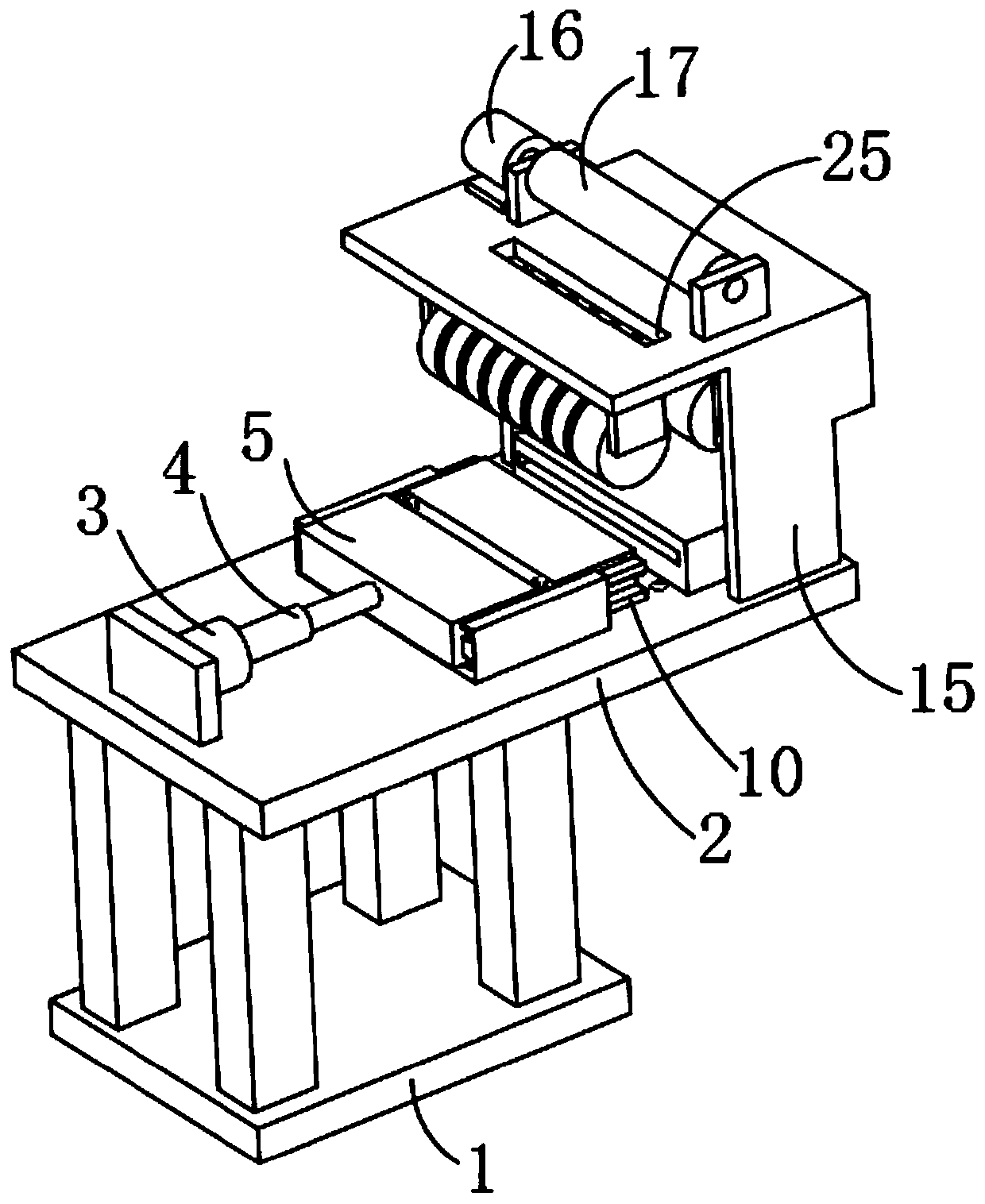

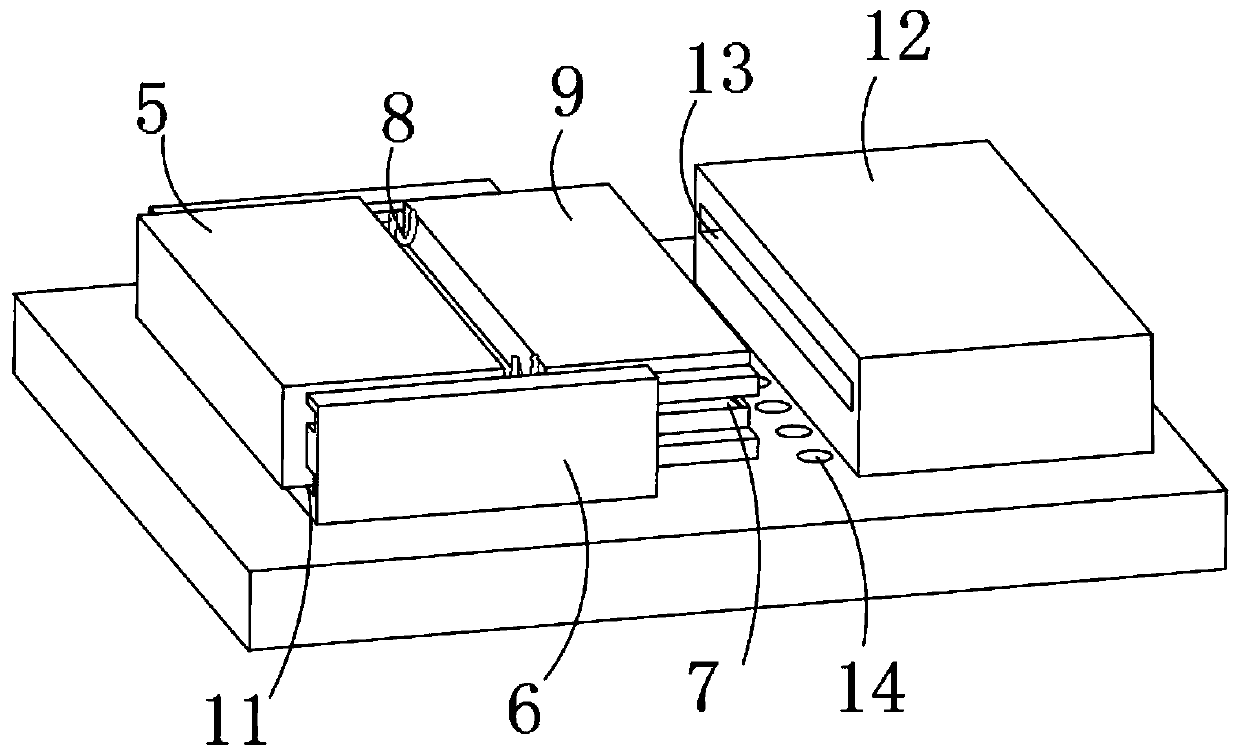

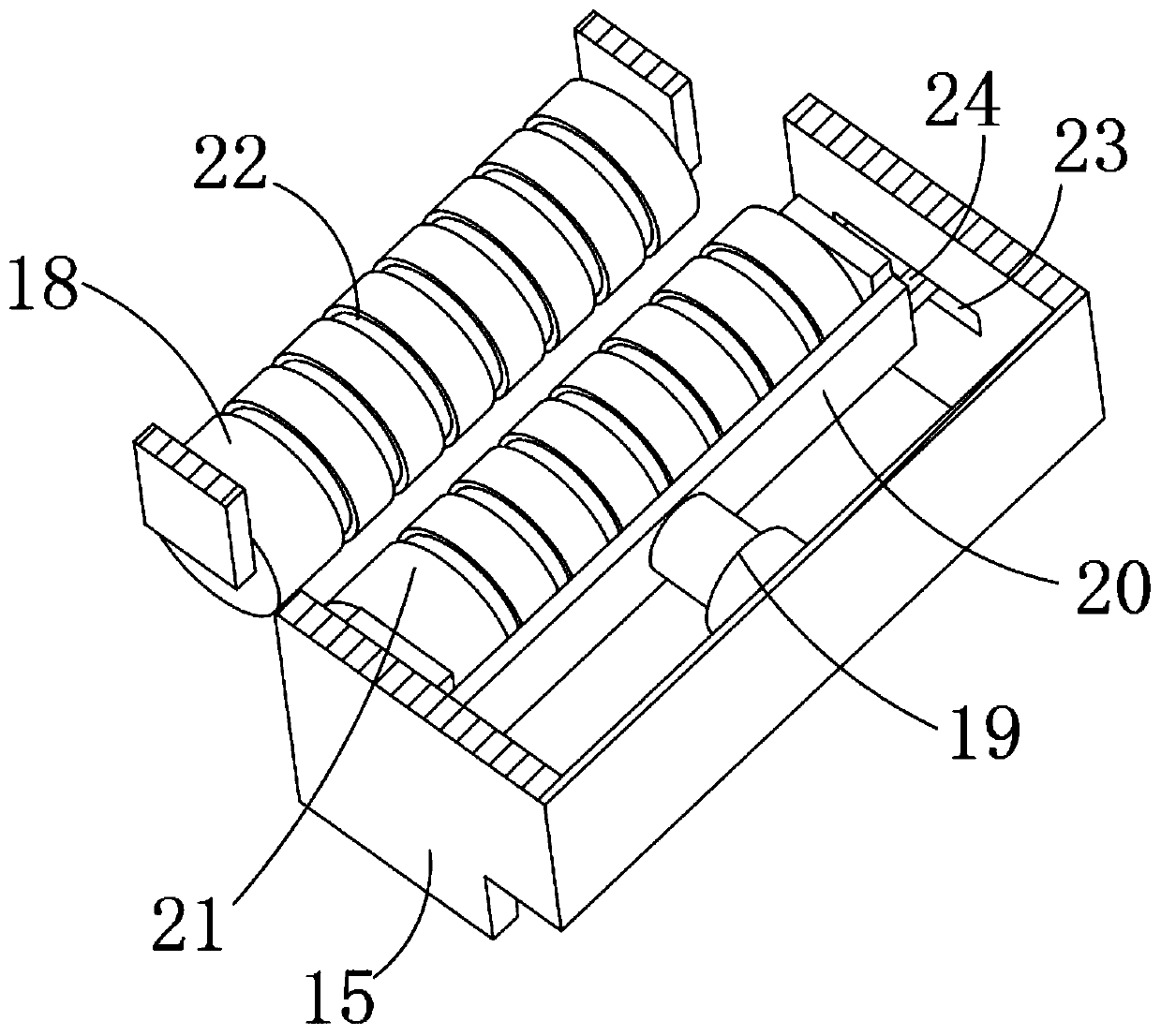

[0024] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an energy-saving chemical fiber cutting machine, a processing platform 2 is installed on the top of the base 1, a mounting seat 6 is installed in the middle of the top of the processing platform 2, and a mounting seat 6 is installed in the middle of the mounting seat 6. Groove 11, the top of the processing platform 2 is located on one side of the mounting seat 6, and a cylinder 3 is installed. One end of the cylinder 3 is connected to a telescopic rod 4, and one end of the telescopic rod 4 is connected to a push block 5. The push block 5 is embedded and installed in the installation groove. Inside of 11, a cutting tool 7 is installed in the middle of one end of the push block 5 away from the telescopic rod 4, and one end of the push block 5 is located at the two sides of the cut tool 7 and is symmetrically installed with an extrusion spring 8, and one end of the extrusion spring 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com