Low-bounce high-speed electromagnetic actuator

An electromagnetic actuator, high-speed technology, applied in electrical control, machine/engine, fuel injection control, etc., can solve the problems affecting the opening or closing timing of the control valve, affecting the working consistency and life, affecting the accuracy of fuel injection control, etc. Achieve the effect of improving switch control accuracy, prolonging service life and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

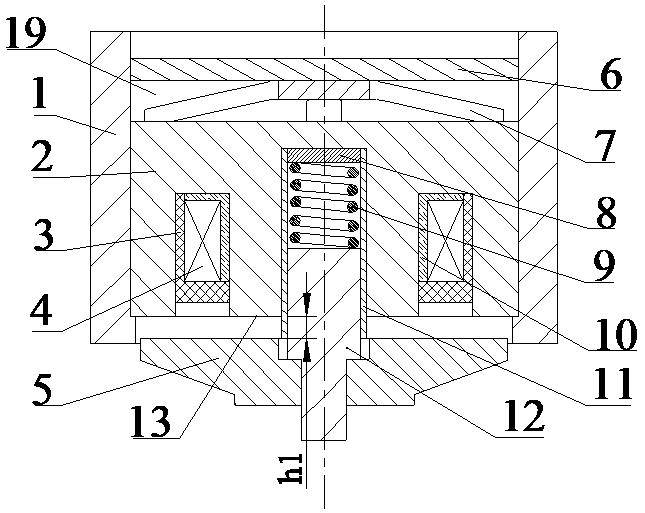

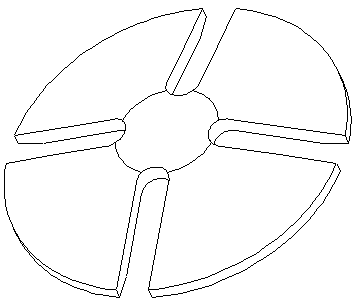

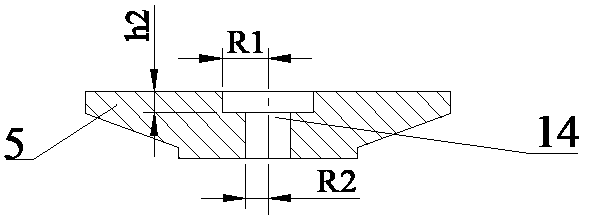

[0019] Embodiment 1: Combining figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the composition of this embodiment includes a housing 1, an iron core 2, a sealing resin 3, a coil 4, an armature 5, a fastening nut 6, a disk leaf spring 7, a spring washer 8, a return spring 9, a coil skeleton 10, a guide Set 11 and armature core 12. There is a stepped through hole in the center of the shell 1, and the upper end is tapped with threads, in which the iron core 2, the disc leaf spring 7 and the fastening nut 6 are installed. The iron core 2 is a cylindrical structure of soft magnetic material, with a ring groove on the end surface and a blind hole in the center. The coil 4 is wound on the bobbin 10, arranged in the ring groove of the iron core 2, and sealed by the sealing resin 3. Sealing is performed, and the height of the sealing resin 3 filling the ring groove is lower than the iron core end surface 13, so as to avoid thermal expansion overflowing the ring groove....

Embodiment approach 2

[0021] Embodiment 2: On the basis of Embodiment 1, the plate spring chamber 19 is filled with compressible oil to further quickly attenuate the energy of the collision between the armature 5 and the guide sleeve 11 and reduce the bounce and vibration of the armature core 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com