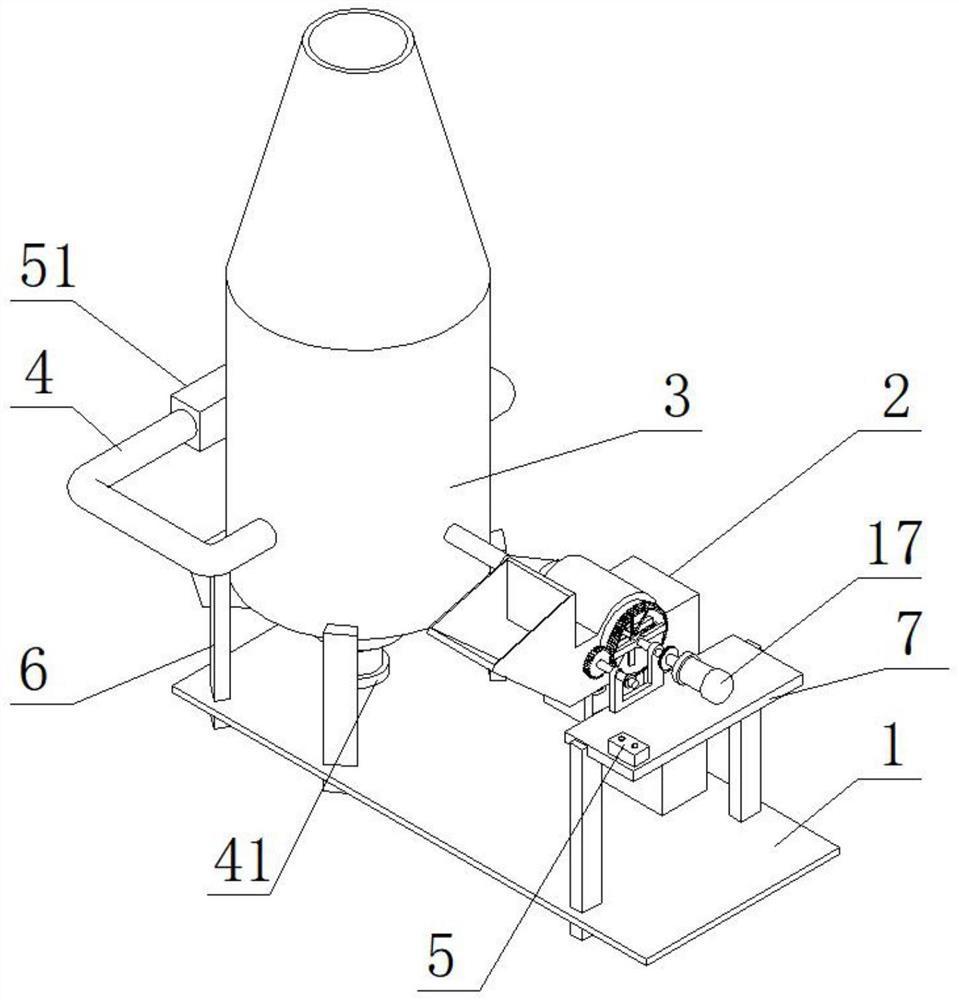

A solid-state slag removal pulverized coal furnace

A slagging coal, solid state technology, applied in solid fuel pretreatment, block/powder supply/distribution, combustion methods, etc. Air entering the furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

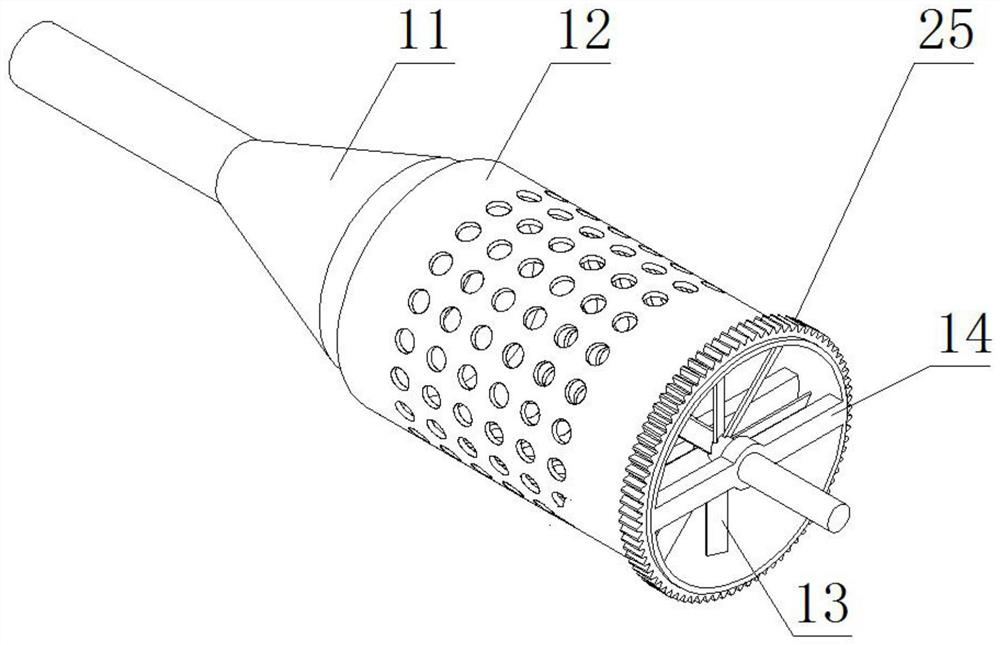

[0033] As a preferred embodiment of the present invention, coal powder holes are provided on the drum punching coal suction device 12 .

[0034] As a preferred embodiment of the present invention, the annular slider 15 and the roller punching coal suction device 12 constitute a sliding pair.

[0035] As a preferred embodiment of the present invention, the wheel shaft 26 is provided with angled blades.

[0036] As a preferred embodiment of the present invention, the elastic plate 35 and the matching hole constitute a sliding pair.

[0037] As a preferred embodiment of the present invention, the other end of the rotary shaft 43 is provided with a turntable 52, and the gap between the turntable 52 and the discharge cover 46 is 0-1 cm.

[0038] As a preferred embodiment of the present invention, a discharge pipe 53 is provided on one side of the discharge cover 46, a slag discharge tank 54 is provided on the bottom frame 1, and the slag discharge pipe 32 and the slag discharge ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com