Automatic dehumidifying device for dam extension line gauge

A technology of wire drawing instrument and wire drawing, which is applied in the direction of heating device, drying gas arrangement, dryer, etc., which can solve the problems of reducing the measurement accuracy of sensors, poor ventilation, and the inability to fundamentally solve the stability problems of wire drawing equipment, etc. problems, to achieve the effect of reducing the workload of manual maintenance, reducing equipment maintenance costs, and improving the environment inside the protection box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

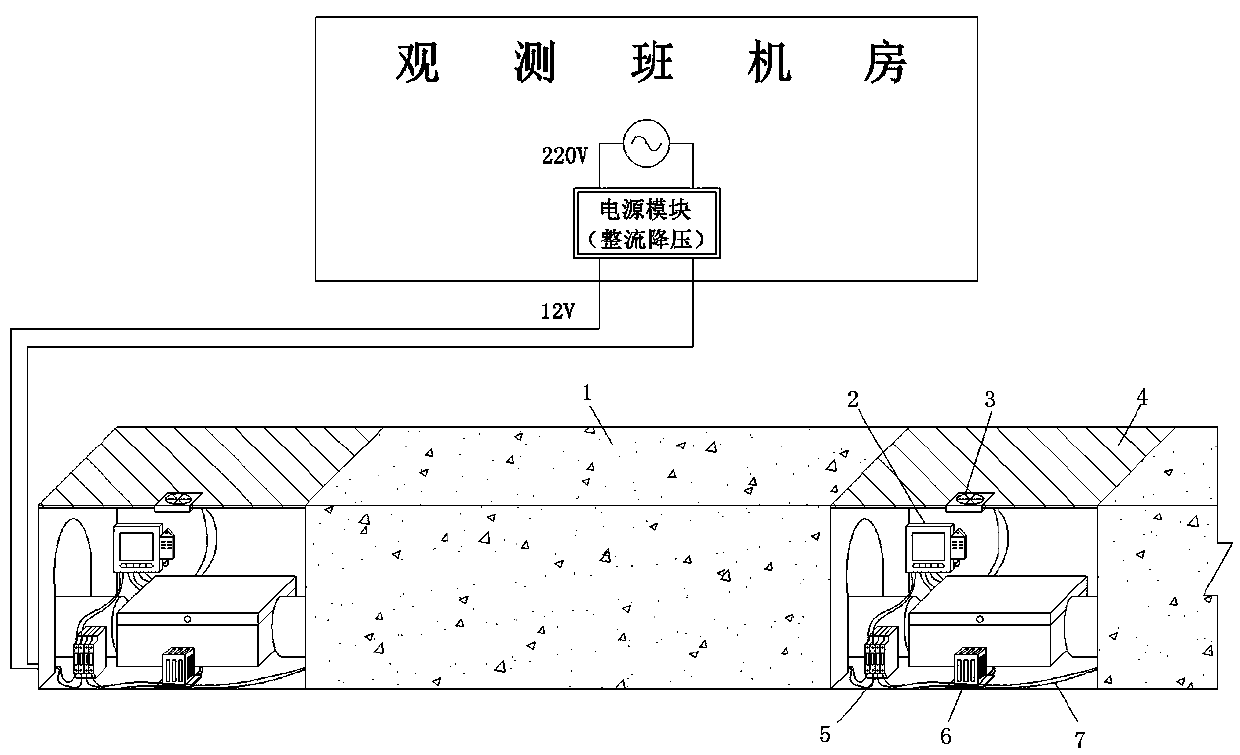

[0012] Such as figure 1 As shown, in the scheme provided in this embodiment: the tension line equipment is buried under the concrete surface 1, and a plurality of measuring points are arranged along the extension direction of the tension line, each measuring point is arranged in a protection box, and the top cover of the protection box 4 is flush with the concrete surface 1; a DC fan 3 is installed on the top cover 4 of the protection box; a DC heater 6 is installed at the bottom of the protection box; a temperature and humidity controller 2 is installed in the protection box; a DC fan 3 and a DC heater 6 The temperature and humidity controller 2 is connected separately. Compared with the temperature and humidity sensor, the temperature and humidity controller 2 can monitor the ambient temperature and humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com