A control method, system and application of a steam drying device

A drying device and control system technology, which is applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of affecting the accuracy of volatile data feedback, large volatile error, and low degree of automation, so as to enhance production safety Performance and stability, stable product quality, and precise control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides an example of drying PVC with the steam drying control method of the present invention.

[0052] The PVC slurry (with a water content of about 80%) prepared and discharged by a conventional polymerization kettle method is separated from most of the water by a centrifuge to obtain a wet PVC with a water content of 20%-25%, and then a screw conveyor is used to form a high-humidity The filter cake is sent to the cyclone drying equipment (steam drying device).

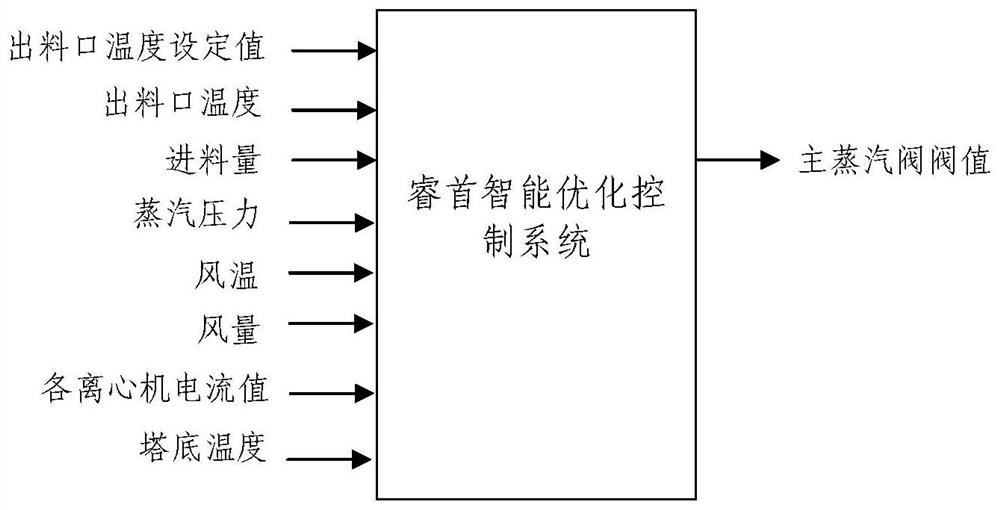

[0053] The Ruishou intelligent optimization control system is bidirectionally connected with the PVC drying DCS system through OPC communication, and the on-site production data is collected in real time through the DCS system. Real-time tracking of the control instructions sent by the DCS control system to realize real-time control and optimal control of field equipment.

[0054] The specific production steps are as follows:

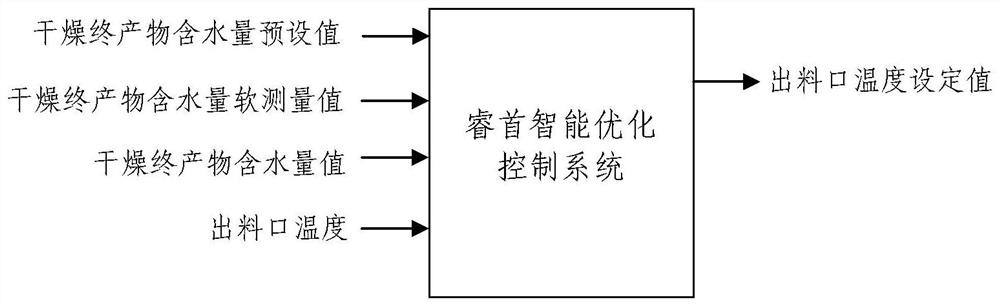

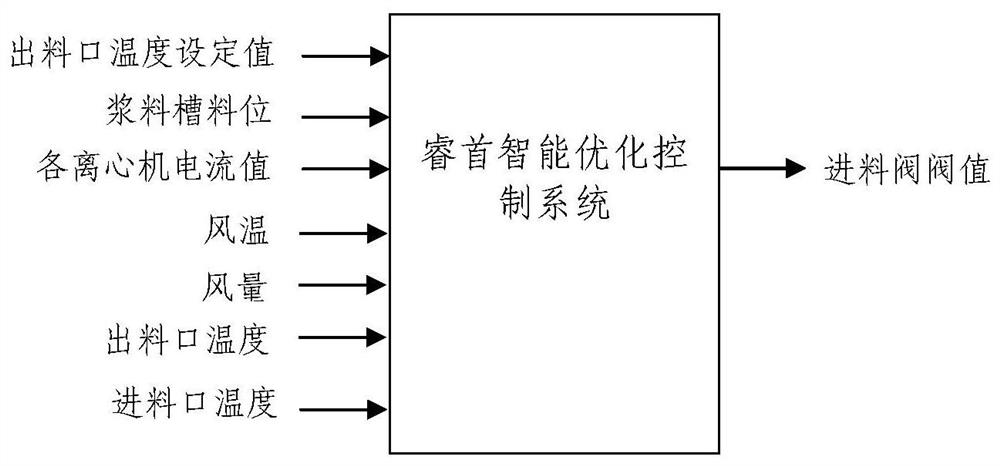

[0055] (1) Ruishou intelligent optimization control system is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com