Automatic drying temperature control method for colored sand line

A technology of drying temperature and control method, which is applied in the direction of pretreatment surface, coating, and the device for coating liquid on the surface, etc. It can solve the problems of large fluctuations in drying temperature, low quality of colored sand, and agglomeration of colored sand, and achieve Stable temperature curve, ensure drying temperature, improve quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

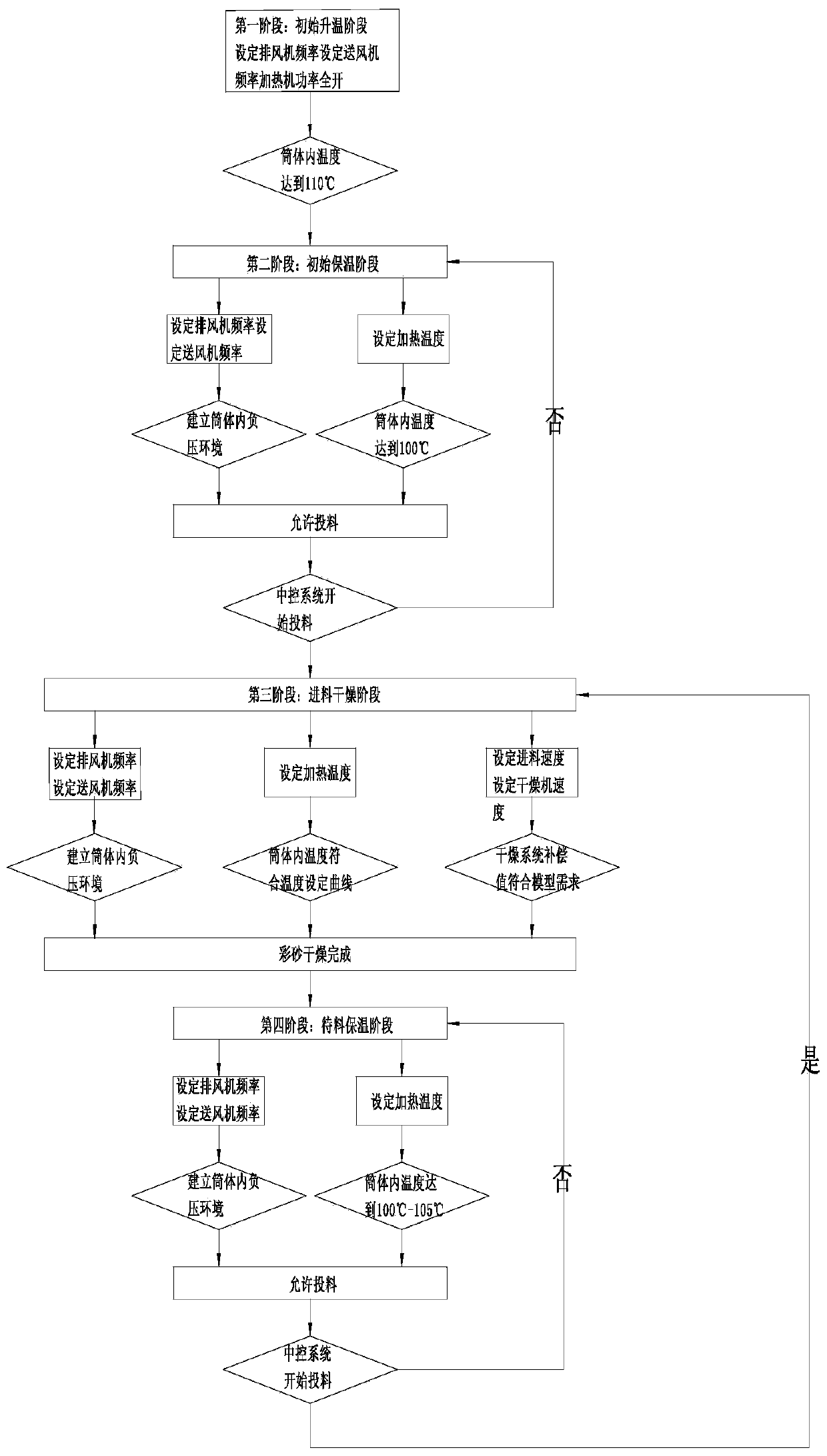

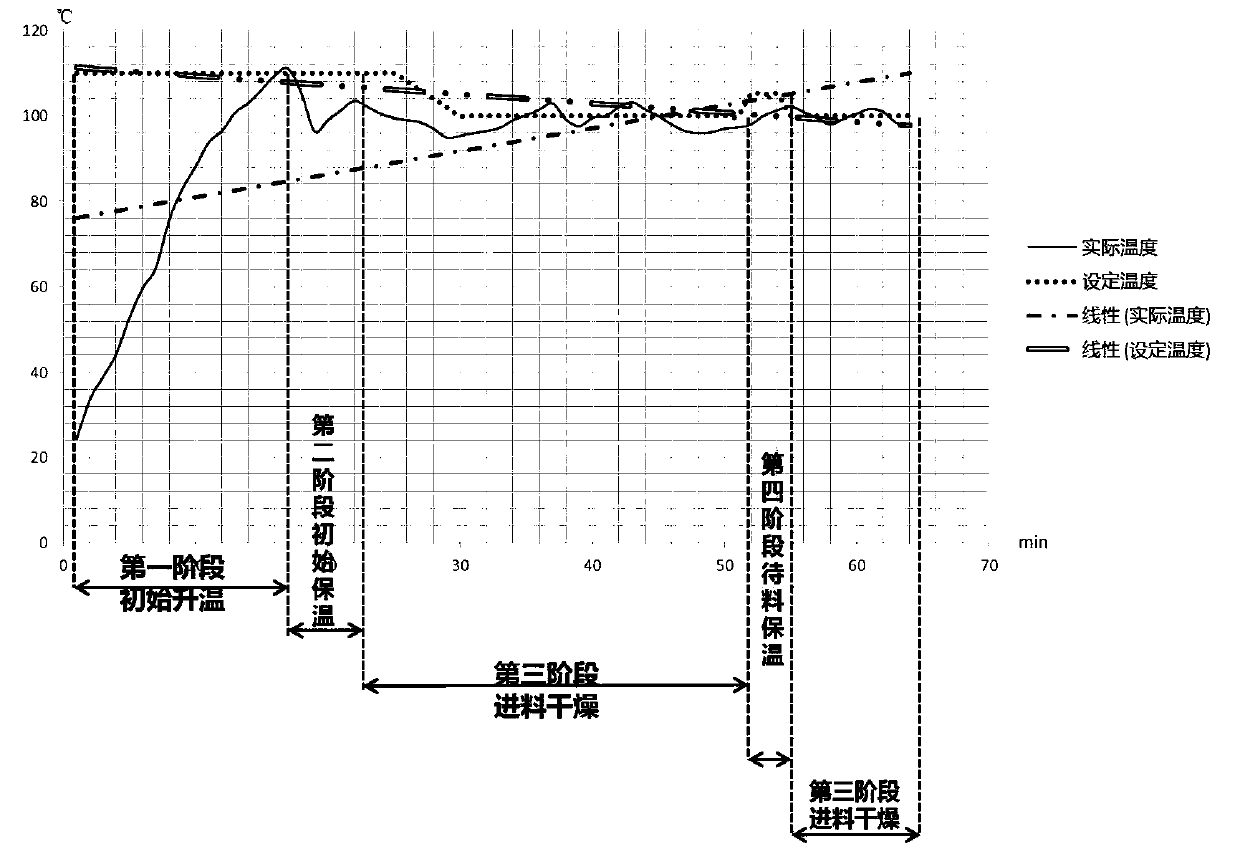

[0056] Hereinafter, taking a drum dryer as an example, the method for controlling the automatic drying temperature of the colored sand line of the present invention will be described in detail.

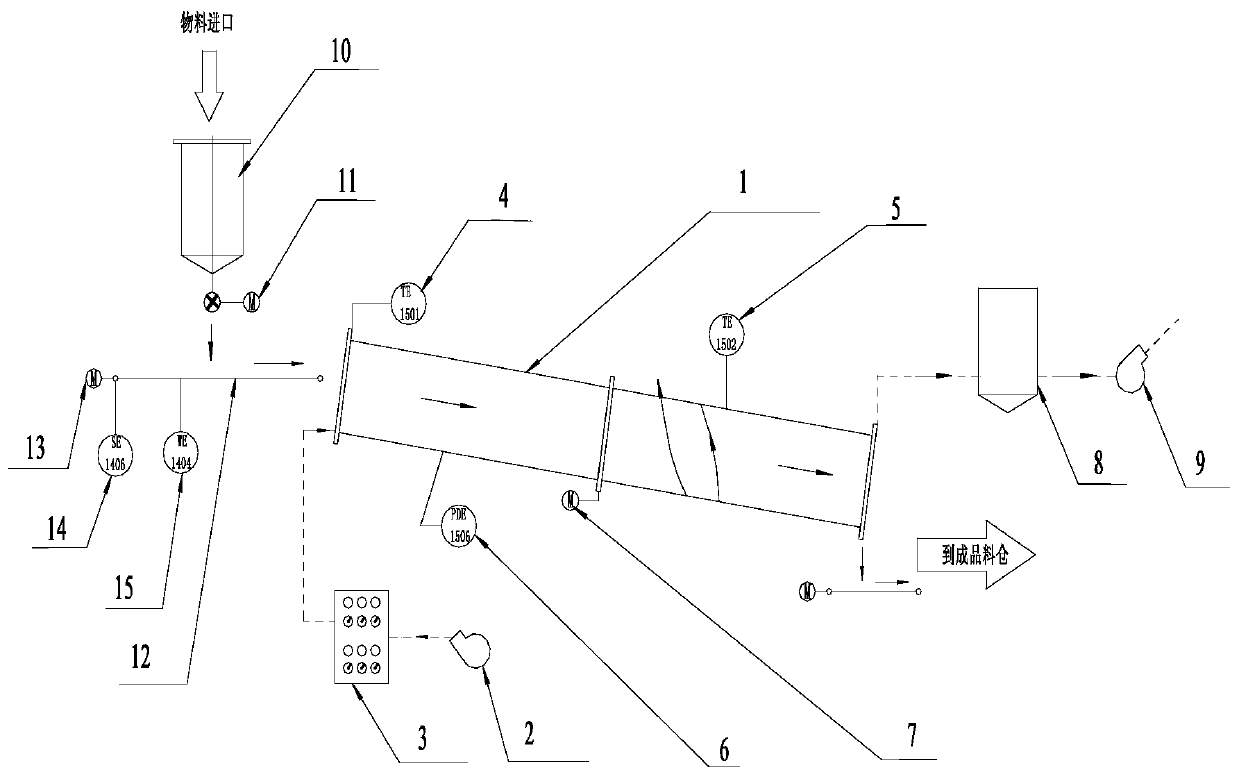

[0057] see figure 2 , the drying system of this embodiment includes a drum dryer 1, the drum dryer 1 is arranged obliquely, the feed end is higher than the discharge end, the feed end of the drum dryer 1 is provided with a colored sand feed port and a hot air inlet, and the blower 2. The heating machine 3 is connected to the hot air inlet in turn. The blower 2 sends the hot air heated by the heating machine 3 into the dryer cylinder for drying colored sand. The heating machine 3 sets the temperature through the temperature controller and temperature sensor, and the power is The amplifier adjusts the heating power of the heater to realize heating closed-loop control; the feed end of the drum dryer 1 is provided with a first temperature sensor 4 for detecting the temperature of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com