Multi-working-condition loaded cutting fluid centralized filtering system reliability test device and method

A filter system and test device technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as corrosion and deterioration of cutting fluid, corrosion of processing equipment, and impact on processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

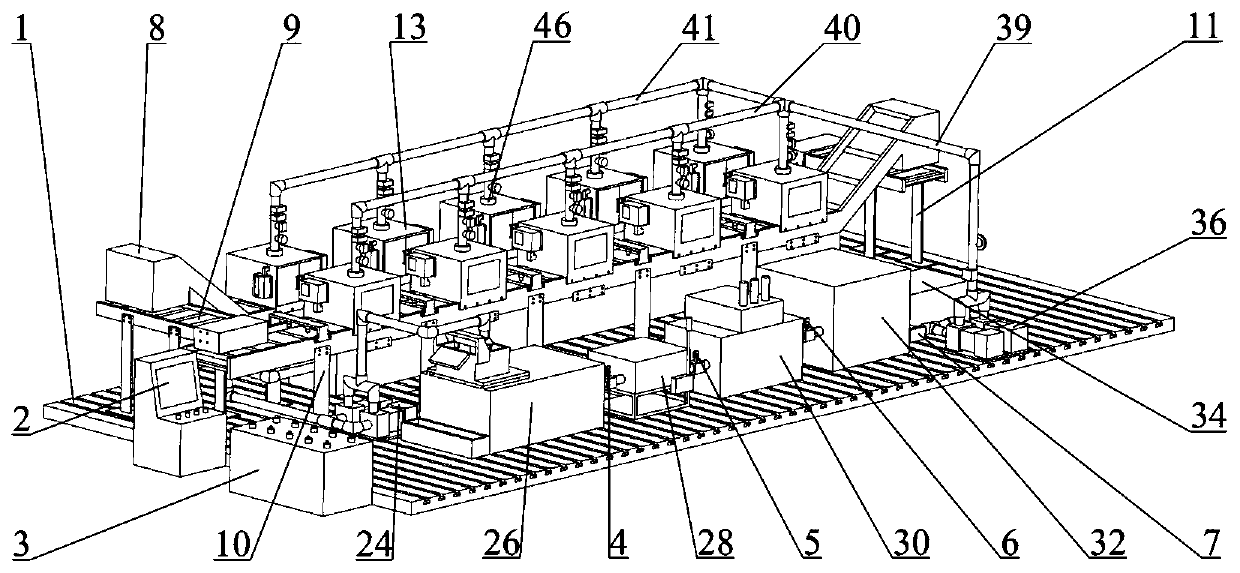

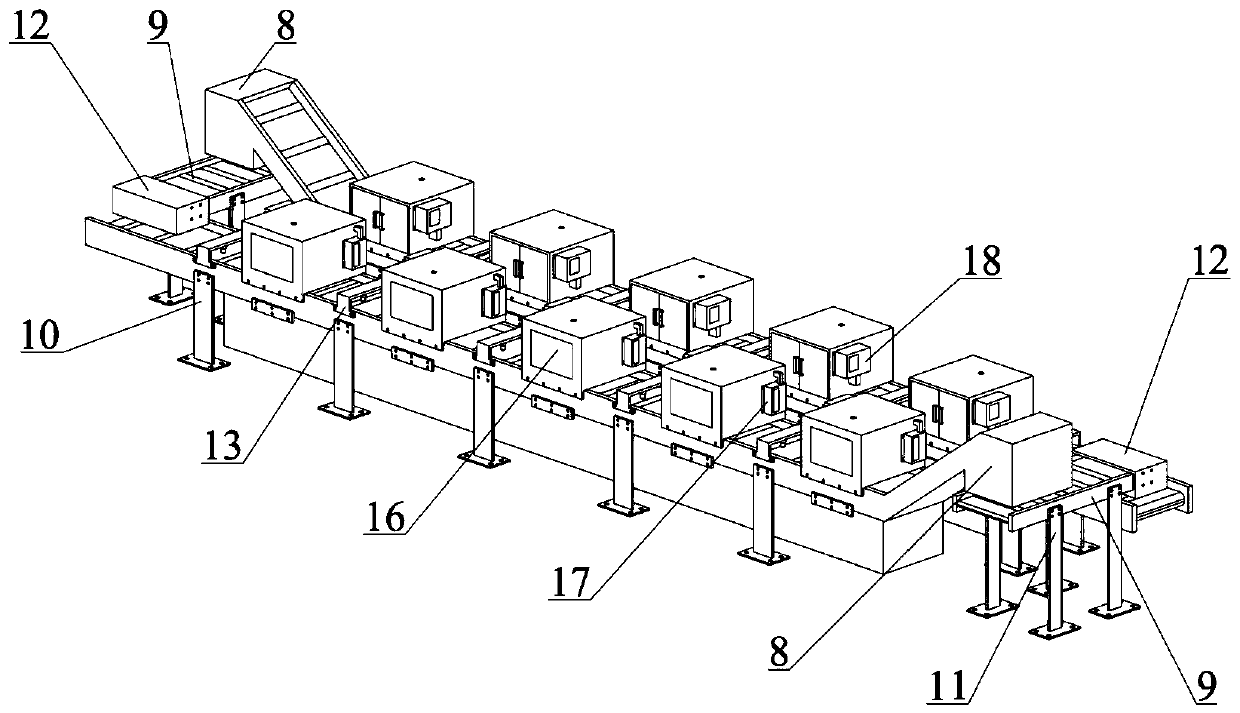

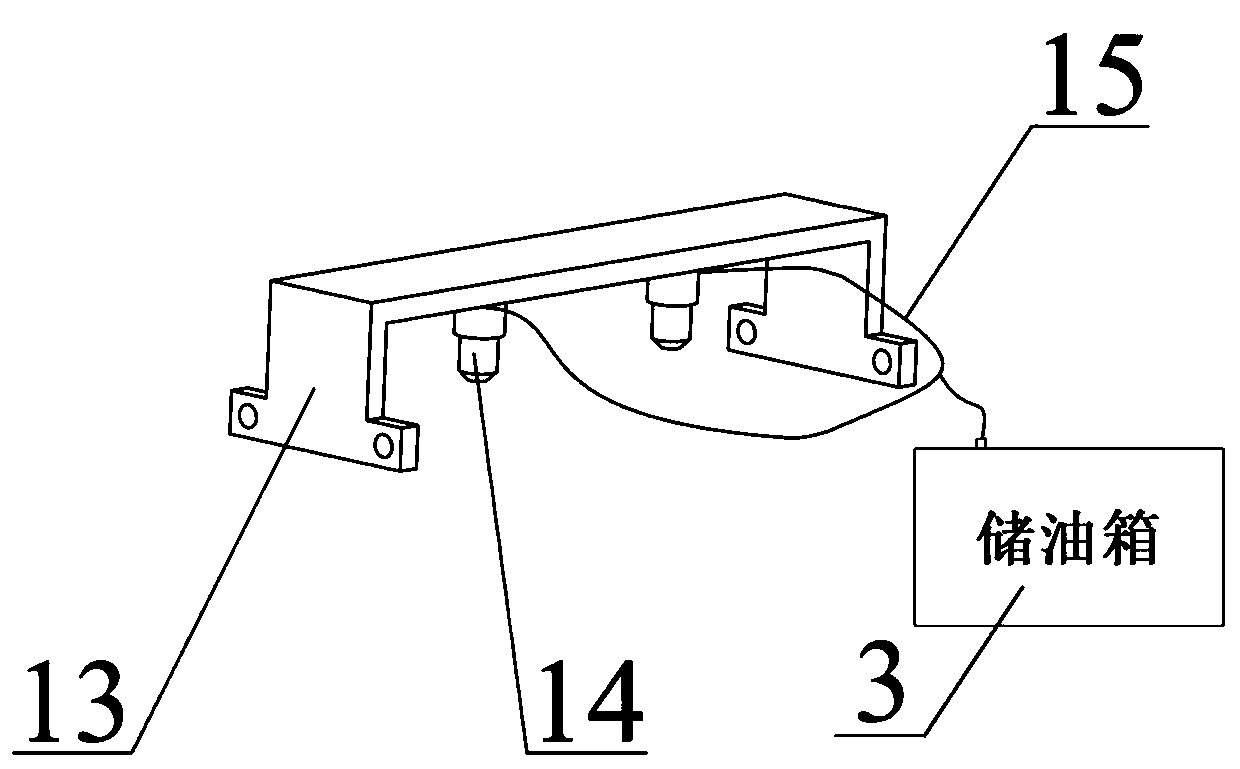

[0097] The device and method for the reliability test of the cutting fluid centralized filtration system include a working condition simulation system, a cutting fluid centralized filtration system, a state detection / monitoring system and auxiliary devices;

[0098] refer to figure 1 , the working condition simulation system, the cutting fluid centralized filtration system and the state detection / monitoring system are installed on the horizontal iron 1 in the auxiliary device, and the horizontal iron 1 is installed on the foundation; the control cabinet 2 and the oil storage tank 3 in the auxiliary device Installed on the ground on the right side of the horizontal iron 1;

[0099] In the working condition simulation system, two chain plate chip conveyors 8 with the same structure are fixedly installed on the lower side of the horizontal iron 1 through the first support plate 10, and the two chain plate chip conveyors 8 with the same structure are installed on the horizontal ir...

Embodiment 2

[0202] Example 2 Reliability Test Method of Cutting Fluid Centralized Filtration System Loaded by Multiple Working Conditions Simulation

[0203] refer to Figure 11 The reliability test method of the cutting fluid centralized filtration system with multi-working condition simulation loading described in the present invention is carried out on the basis of the reliability device of the cutting fluid centralized filtration system with multi-working condition simulation loading mentioned above, specifically including The following steps:

[0204] Step 1: Determine the structural composition of the tested cutting fluid centralized filtration system and the specifications and models of each tested part, and complete the preliminary preparations for the test, including the following steps:

[0205] (1) Determine the number of cutting fluid supply branches to be tested and the installation sequence of each tested part;

[0206] (2) Determine the specifications and models of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com