Anemograph adjusting device and method and electronic equipment

An anemometer and adjustment technology, which is used in measurement devices, testing/calibration of speed/acceleration/impact measurement equipment, instruments, etc., can solve problems such as low efficiency, cumbersome process, and many input parameters, so as to reduce dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

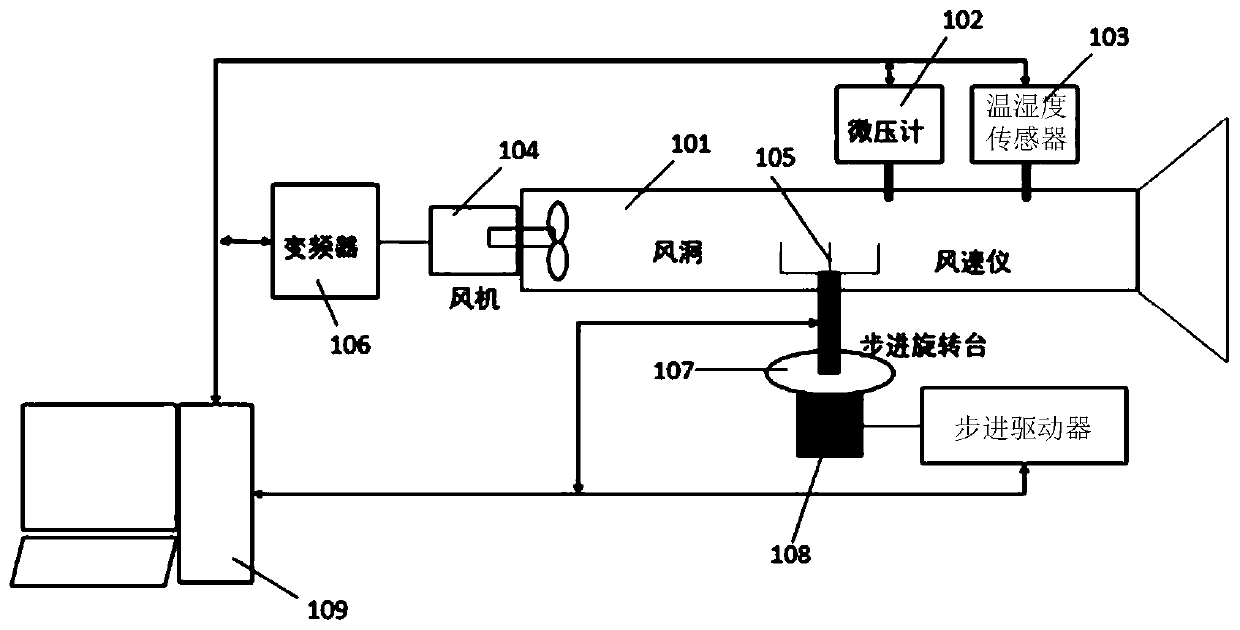

[0056] refer to figure 1 A schematic diagram of an anemometer calibration device is shown, including a wind tunnel 101, a micromanometer 102, a temperature and humidity sensor 103, a fan 104, and an anemometer 105 arranged inside the wind tunnel 101; the fan 104 is also connected to a frequency converter 106 Anemometer 105 also links to each other with stepping turntable 107, and stepping turntable 107 is provided with stepper motor and step driver 108 that are connected; Anemometer 105, micromanometer 102, temperature and humidity sensor 103, frequency converter 106 and The stepper drivers 108 are all connected with the controller 109 .

[0057] Wherein, the stepper driver 108 rotates the stepper motor to the coded zero point position according to the zero point command sent by the controller 109 .

[0058] The fan 104 rotates to provide the wind source for the wind tunnel 101 .

[0059] Both the micromanometer 102 and the temperature and humidity sensor 103 are used to obt...

Embodiment 2

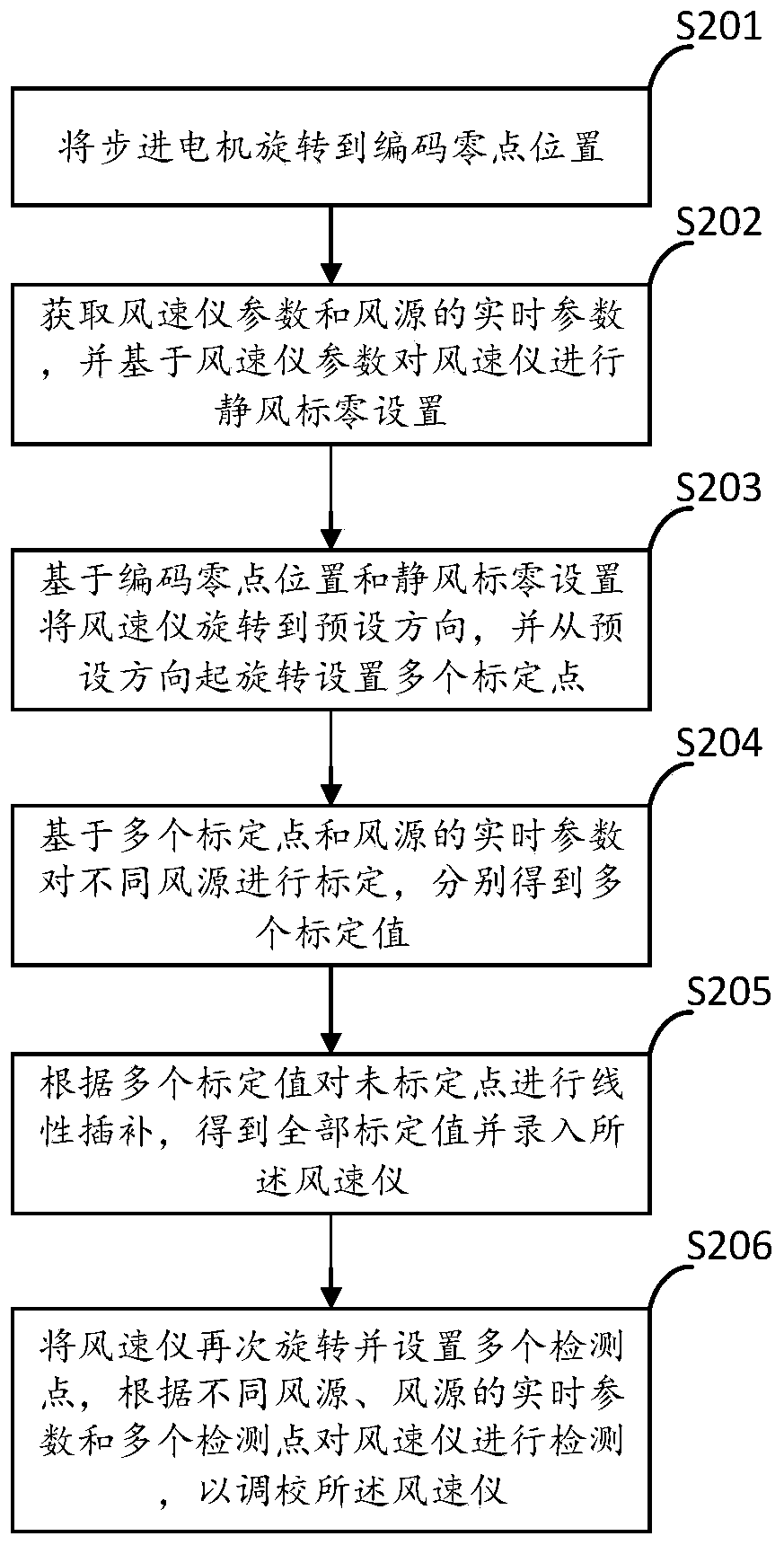

[0071] refer to figure 2 The flowchart of an anemometer calibration method shown can be executed by the controller in the anemometer calibration device of Embodiment 1. The controller can be an electronic device such as a computer or a processor. The method mainly includes steps S201 to S201. S206:

[0072] Step S201, rotating the stepper motor to the code zero position.

[0073] In a specific embodiment, the controller includes but is not limited to a PC, and the PC software sends an instruction to return the stepper motor to absolute zero (ie, the coded zero position). Then install the detected anemometer at a difference of 45 degrees from the horizontal direction. In the end, it is controlled by one key of the PC to realize the fully automatic process of label recording and inspection and report generation. The stepper motor is a stepper motor with integrated encoding, which can read the position signal. The control of the stepper motor is realized by setting the regis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com