Patents

Literature

39results about How to "Little artificial dependence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

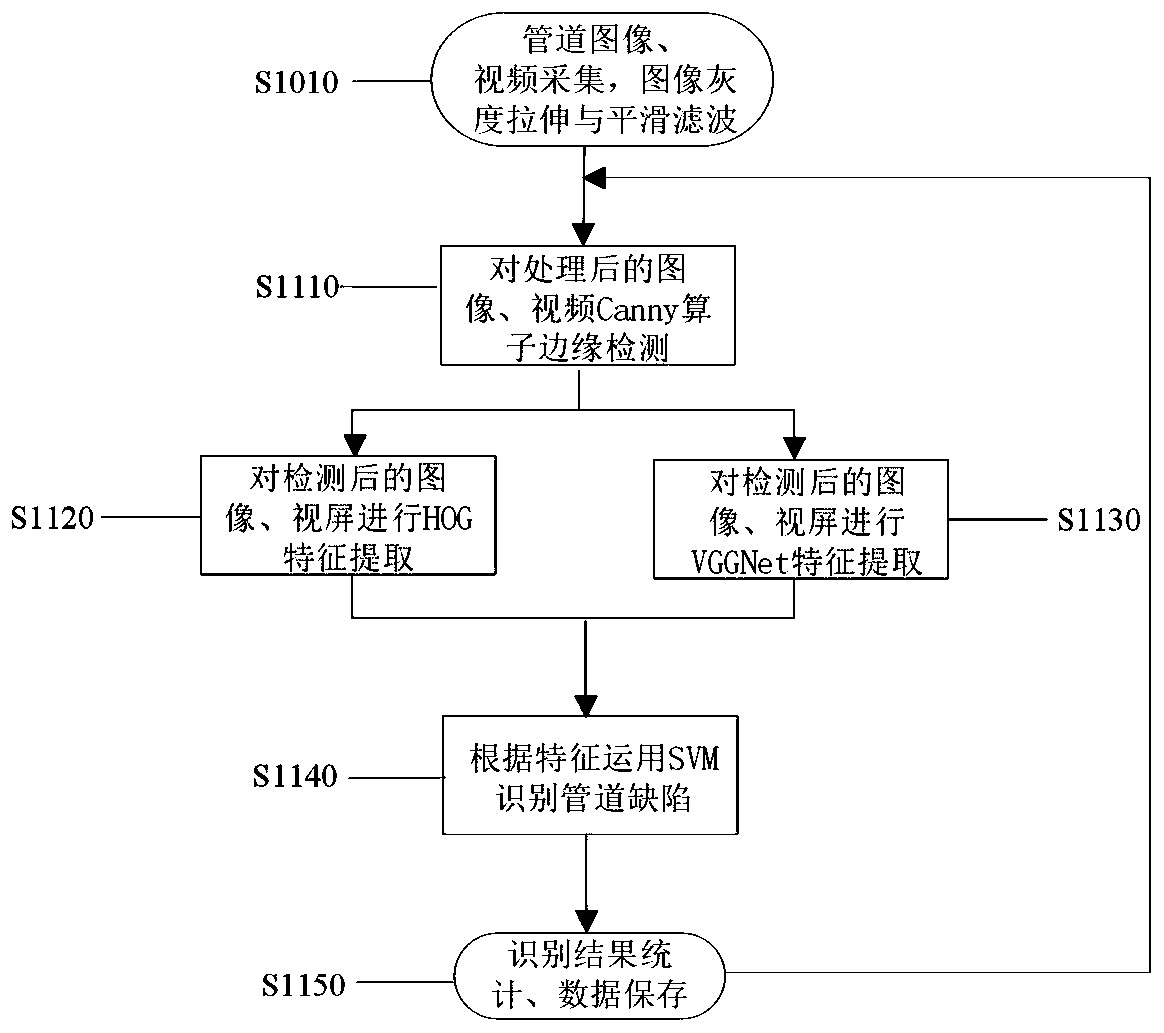

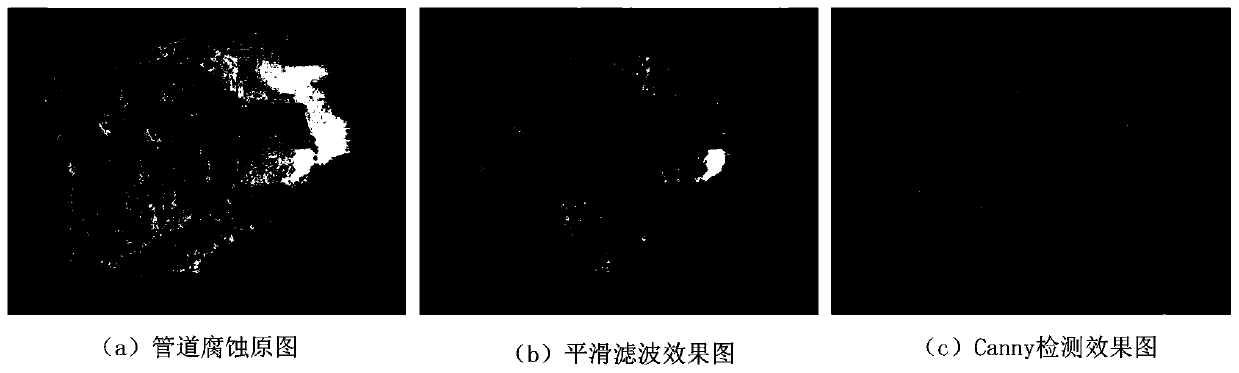

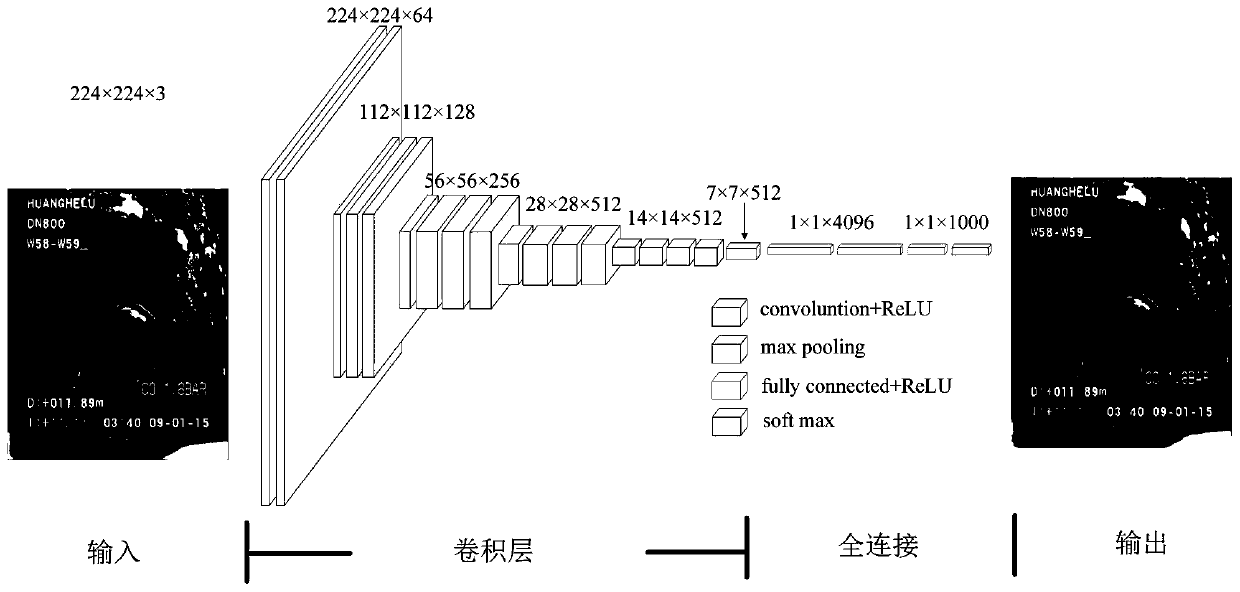

Pipeline defect identification method based on computer vision and machine learning

ActiveCN109800824AImprove efficiencyReduce dependenceCharacter and pattern recognitionComputer basedImaging Feature

The invention relates to a pipeline defect identification method based on computer vision and machine learning. The method comprises the following steps: carrying out gray scale stretching on pipelineimages and videos collected by a pipeline robot; performing sliding filtering processing to filter noise interference; extracting the outline of the suspected defect area by adopting a Canny operator; dividing the acquired image into gradients or edge direction histograms of all pixel points in a cell unit, and combining the histograms to extract HOG features of the image; training a VGGNet modelby adopting a transfer learning strategy, and extracting image features by adopting a trained VGGNet feature extractor; fusing the HOG features of the pipeline image and the features extracted by theVGGNet, classifying the features by using an SVM, and identifying the pipeline defects; and counting the pipeline defect identification result and outputting the pipeline defect type. Defect characteristics of a real pipeline environment can be recognized, robustness and recognition accuracy of a classification model are improved, system image processing speed and recognition efficiency are improved, and the method is suitable for the field of urban pipeline and industrial pipeline maintenance.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

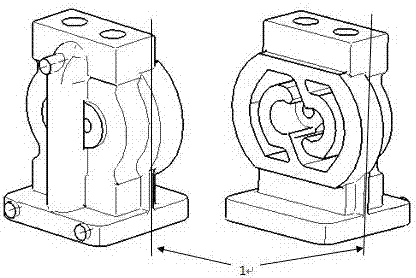

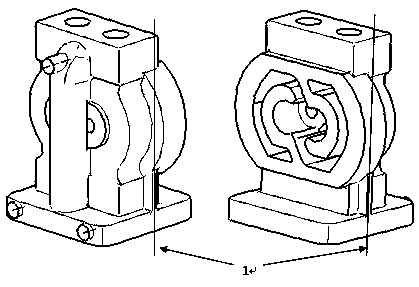

Mixed child-mother core assembly molding technology

ActiveCN107350429ASlow down depreciationIncrease the number ofAdditive manufacturing apparatusFoundry mouldsUltimate tensile strengthProduct Part

The invention discloses a mixed child-mother core assembly molding technology. A 3D printing molding technology and a sand mixing molding technology are combined, a part which is close to a product part having a plurality of structural features adopts 3D printing, and the other parts which have less structural features adopt the traditional sand mixing molding technology method, therefore an assembled sand mold which works through cooperative using of a mother core and a child core is formed. Based on the advantages of an original 3D printing molding technology, a traditional sand mixer production technology is introduced, the two molding technologies are combined with each other, further the cost of raw materials and the equipment investment cost are lowered, and meanwhile, child-mother separated core combination is conducted on a sand molding part which is brought out of a casting and the mold thickness which is brought out of a casting system and improves the strength so as to widen thinking for later multi-technology combination; the number of castings in a single sand box is increased, the sand box utilization ratio and the production efficiency are improved, the dependence on manual work is reduced at the same time, the cost of 3D printing raw materials and the depreciation of the equipment are reduced, and meanwhile, waste of molten iron is avoided, and the purposes of cost reduction and efficiency improvement are achieved.

Owner:四川共享铸造有限公司

Intelligent multi-stage riverway desilting method

InactiveCN111764455AClean up thoroughlyImprove efficiencySoil-shifting machines/dredgersSatellite radio beaconingTerrainRiver routing

The invention discloses an intelligent multi-stage riverway desilting method. The bottom terrain and silt layer thickness distribution information of a riverway is measured through a sonar test set; during sonar detection, sonar detection is carried out at two kinds of different frequencies at the same time, one frequency is matched with detection of a river bottom silt layer, and the other frequency is matched with detection of a riverbed bottom original structure of a non-silt layer. One measured area of the riverway is divided into multiple small areas, a calculation model is set up, and the riverway silt deposition thickness is estimated. Detected large solid garbage is subjected to targeted excavation and clearing though a crane and an excavator of corresponding types. For silt severely afflicted area reach dikes and cutoff riveways tested by a sonar system, riverway river water between dams is exhausted to the rated mixing depth of prepared stirring equipment, and then a high-pressure water gun is adopted for washing away river bottom silt. An amphibious backacting shovel type desilting machine and a chain bucket type bucket-ladder dredger are put into service with targets toachieve desilting step by step. The desilting method is high in desilting efficiency and good in effect.

Owner:尹东

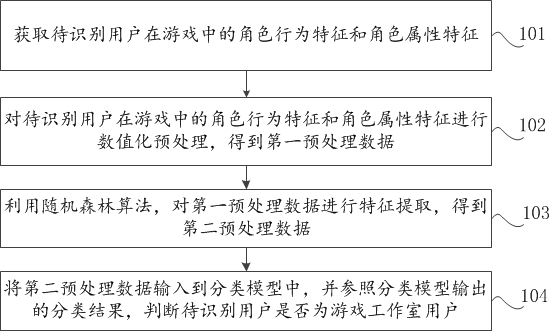

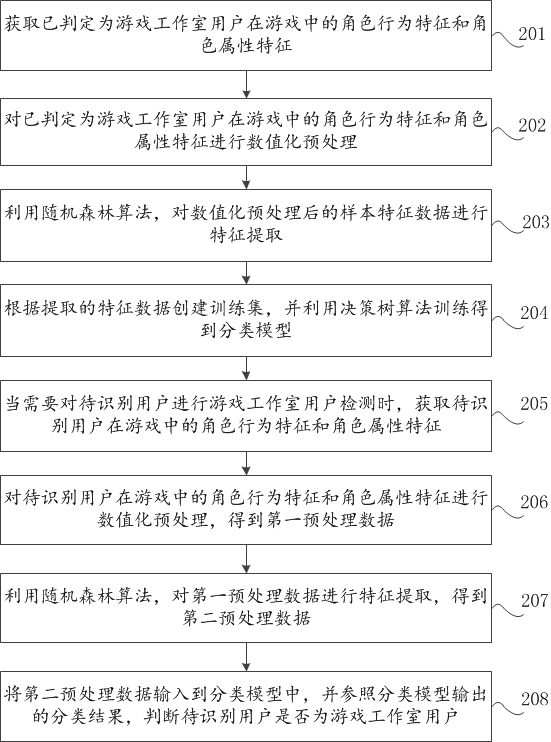

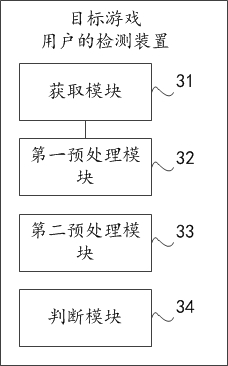

Target game user detection method, device and equipment

ActiveCN111773732AImprove detection accuracyPrivacy protectionCharacter and pattern recognitionVideo gamesFeature extractionEngineering

The invention discloses a target game user detection method, device and equipment, and relates to the technical field of data processing. The method comprises the steps: firstly, performing role behavior characteristics and role attribute characteristics of a to-be-recognized user in a game, and obtaining first preprocessing data; performing feature extraction on the first preprocessed data by using a random forest algorithm to obtain second preprocessed data; and inputting the second preprocessed data into a classification model, and judging whether the user to be identified is a game studiouser or not by referring to a classification result output by the classification model, the classification model being obtained by training based on role behavior characteristics and role attribute characteristics of the game studio user in the game. By applying the scheme of the invention, the detection accuracy of the game studio user can be improved, and the game experience of other normal players cannot be influenced. Manual dependence is reduced, and detection of game studio users can be completed automatically.

Owner:BEIJING PERFECT WORLD SOFTWARE TECH DEV CO LTD

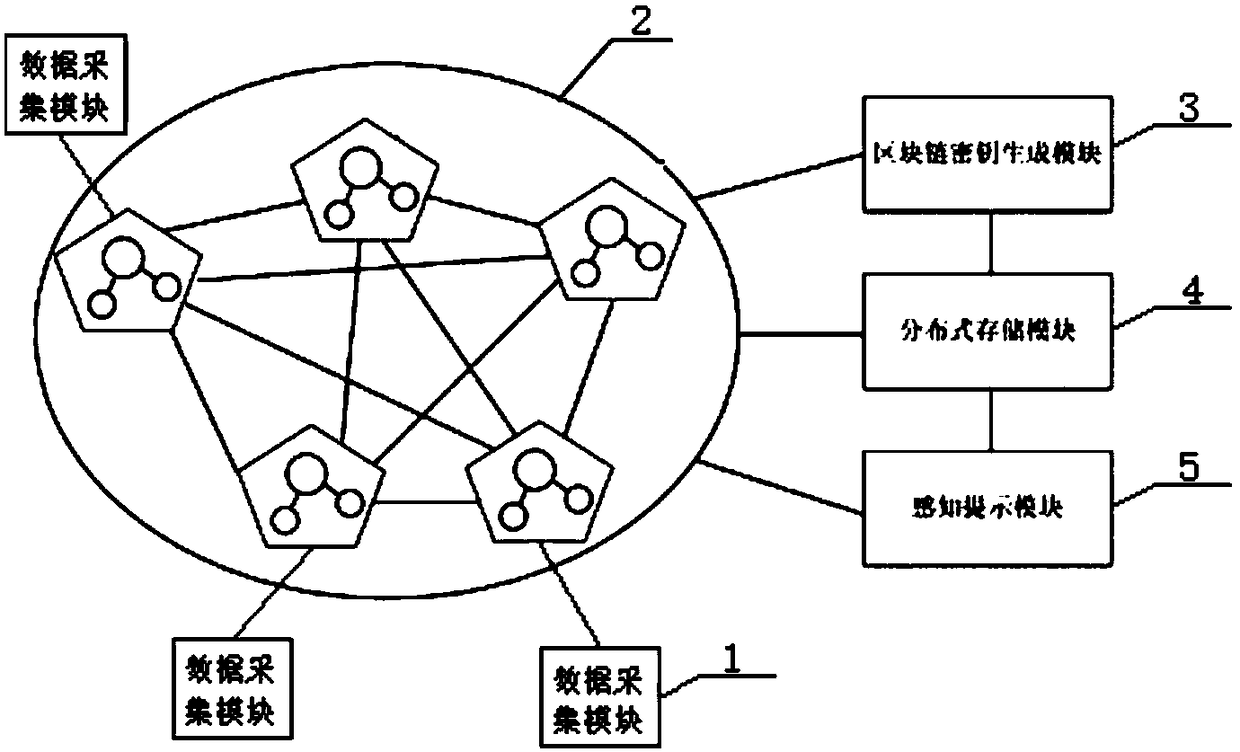

A medical monitoring platform based on block chain and internet of things

InactiveCN109271799AImprove securityLittle artificial dependenceDigital data protectionClosed circuit television systemsKey generationBlockchain

The invention relates to a medical monitoring platform based on a block chain and an Internet of things, comprising the following steps of: collecting video monitoring information at a monitoring nodein multiple directions of each Internet of things, cutting and splicing the video monitoring information to generate medical video information and transmitting the medical video information to corresponding monitoring node;the block chain key generation module using the block chain technology to generate the corresponding block chain key by encrypting the medical video information of each supervisory node in the distributed block chain grid, the distributed storage module storing the block chain key in all the supervisory nodes of the distributed block chain grid, each supervisory node communicating with each other in the distributed block chain grid, if the medical video information of any supervisory node is modified, the block chain key generation module generating the corresponding block chain key, and perceiving other supervisory nodes and prompting by the perceptual prompt module. Compared with the prior art, the invention provides a powerful intelligent platform tool, which has high safety, low management cost and low artificial dependency.

Owner:深圳马来先生生物科技有限公司

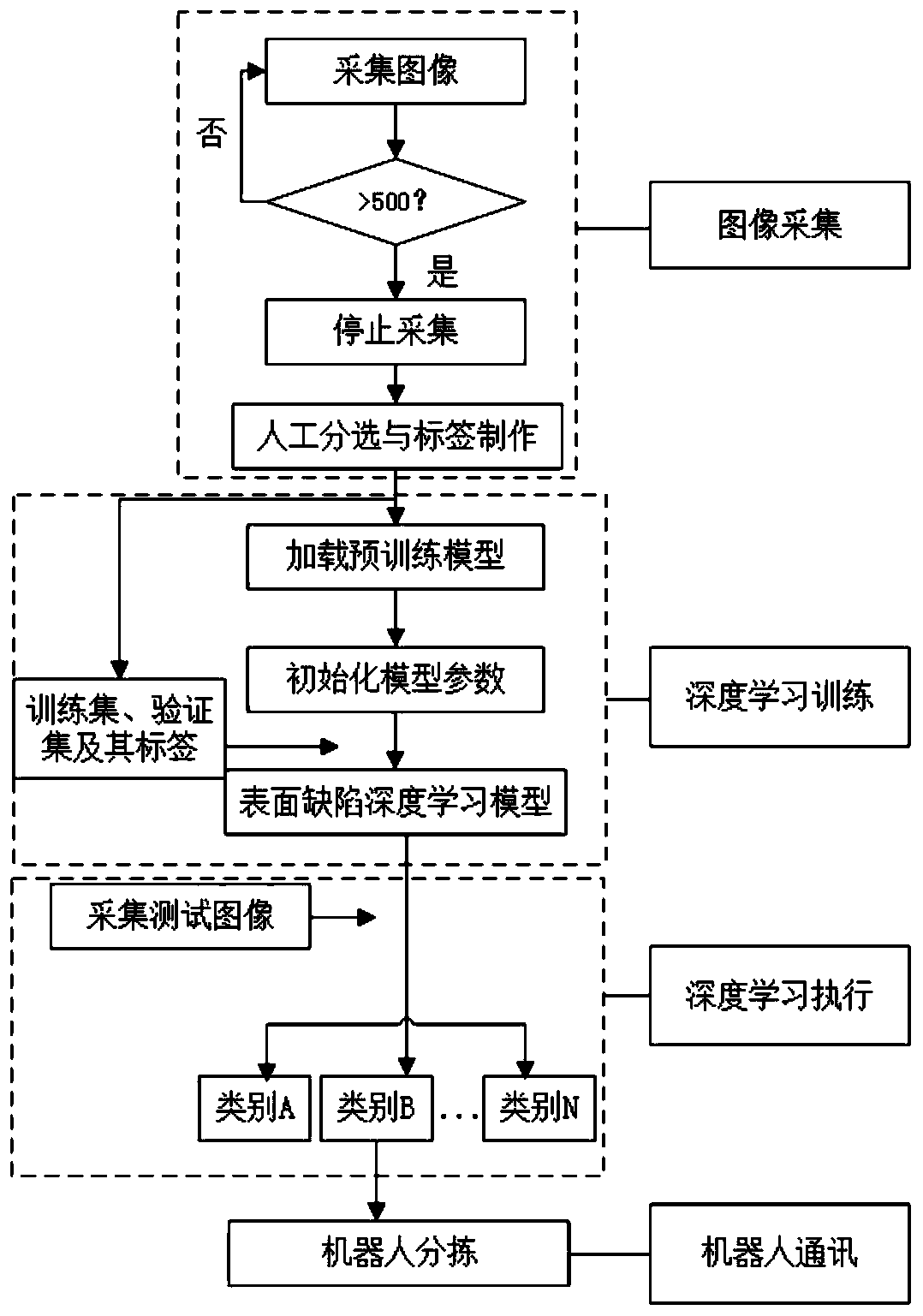

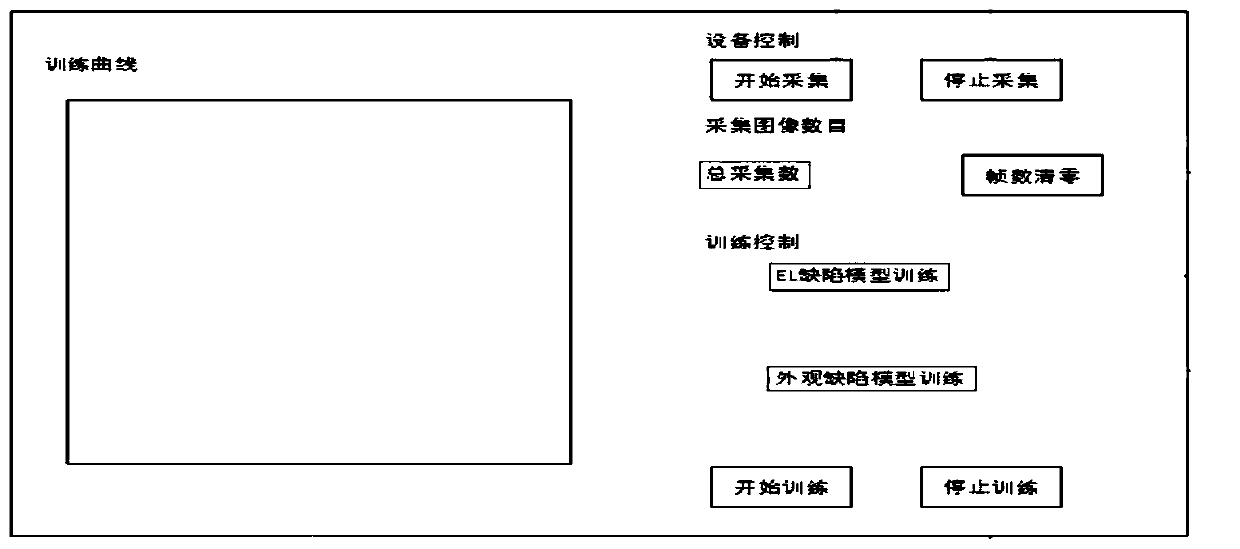

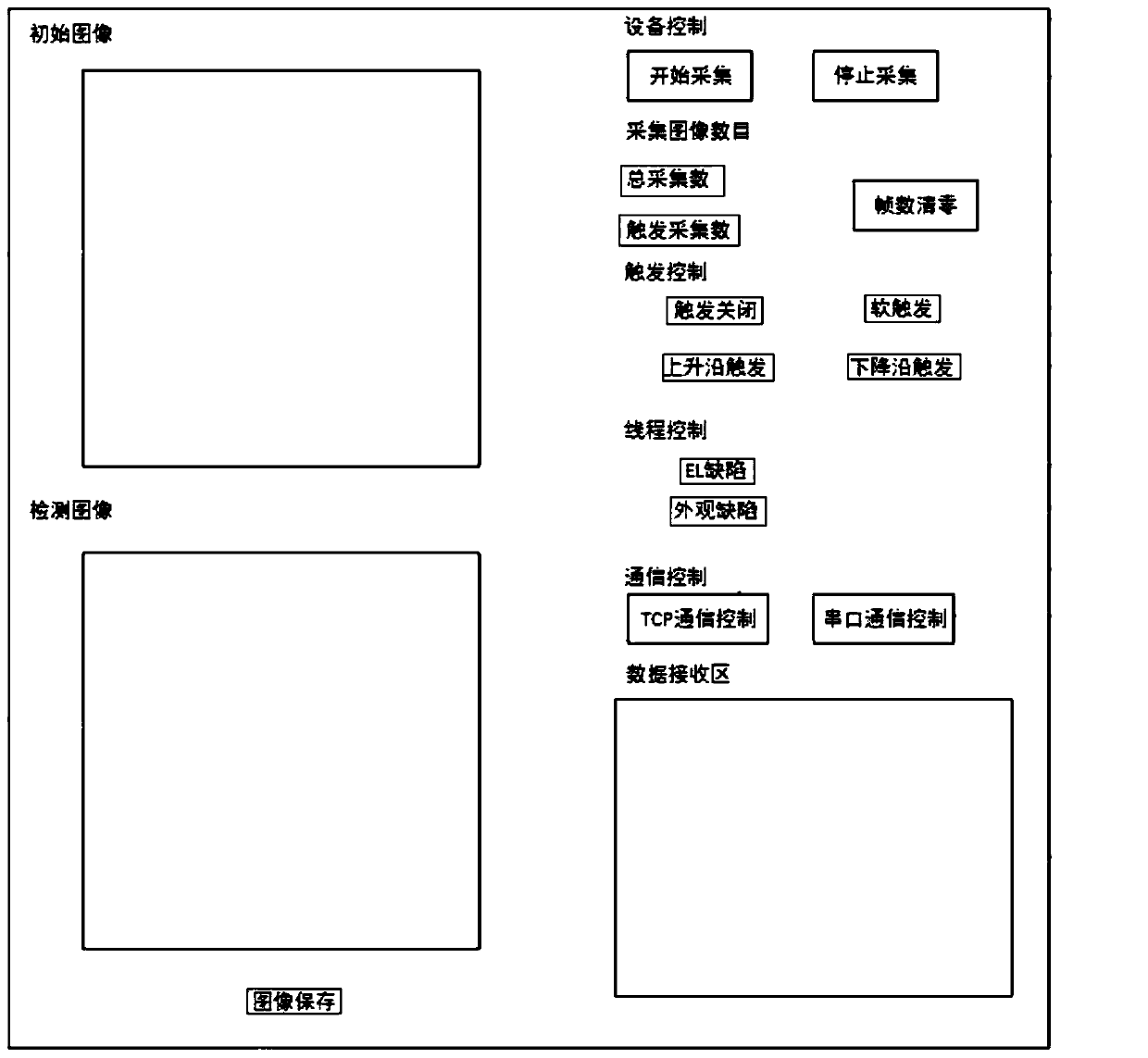

Deep learning recognition and control method and device for photovoltaic cell visual sorting

InactiveCN110473806AImprove intelligenceStrong feature extraction abilitySemiconductor/solid-state device manufacturingSortingPattern recognitionFeature extraction

The present invention provides a deep learning recognition and control method for photovoltaic cell visual sorting. A defect classification and detection method based on deep learning is integrated with an industrial manufacturing process to have high intelligence. The deep learning replaces a traditional learning method to have a high feature extraction capacity, especially when background interference is serious and defects are difficult to identify by the traditional method. In addition, the deep learning recognition and control device can automatically perform defect feature extraction, the processing speed is improved, and the manual dependence is reduced.

Owner:HEBEI UNIV OF TECH +1

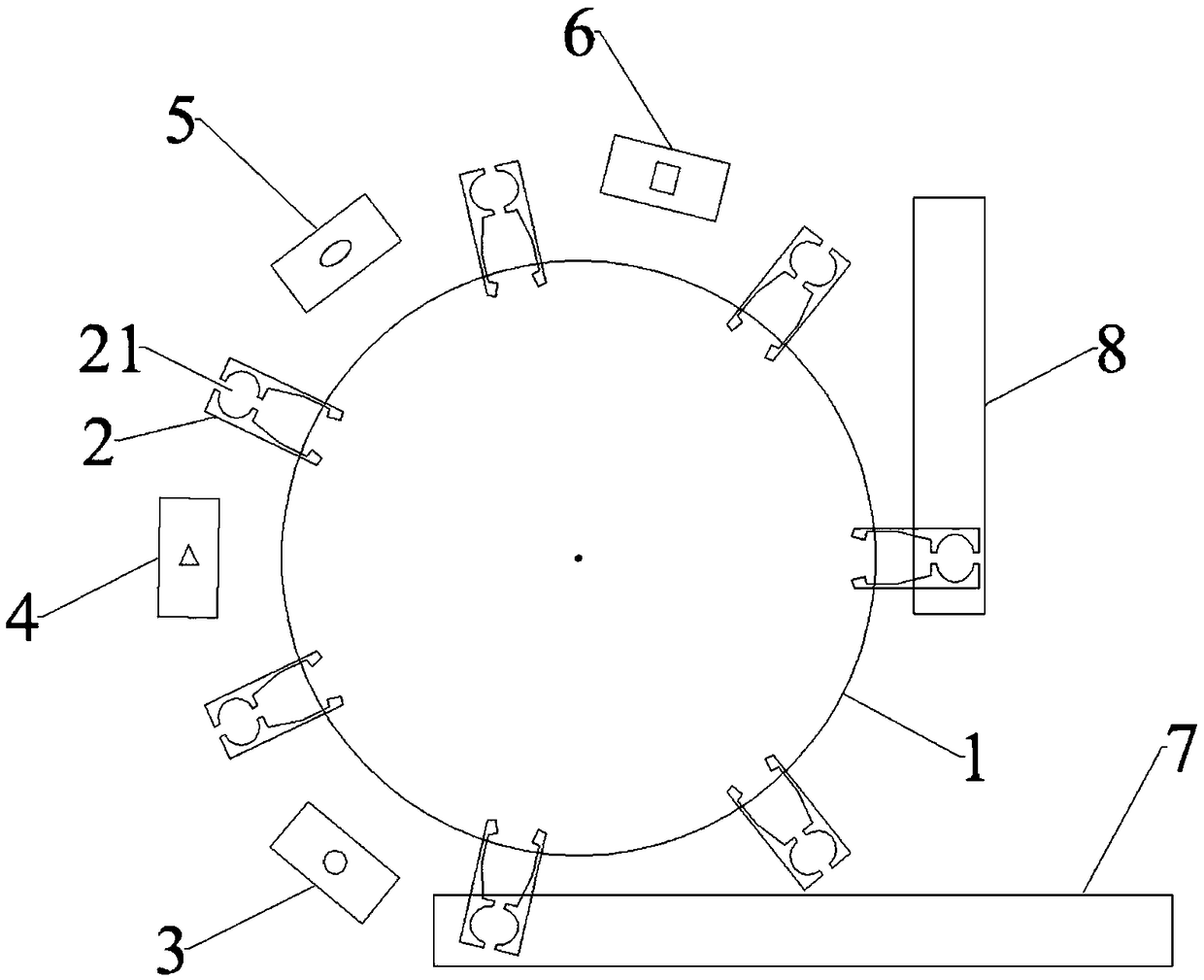

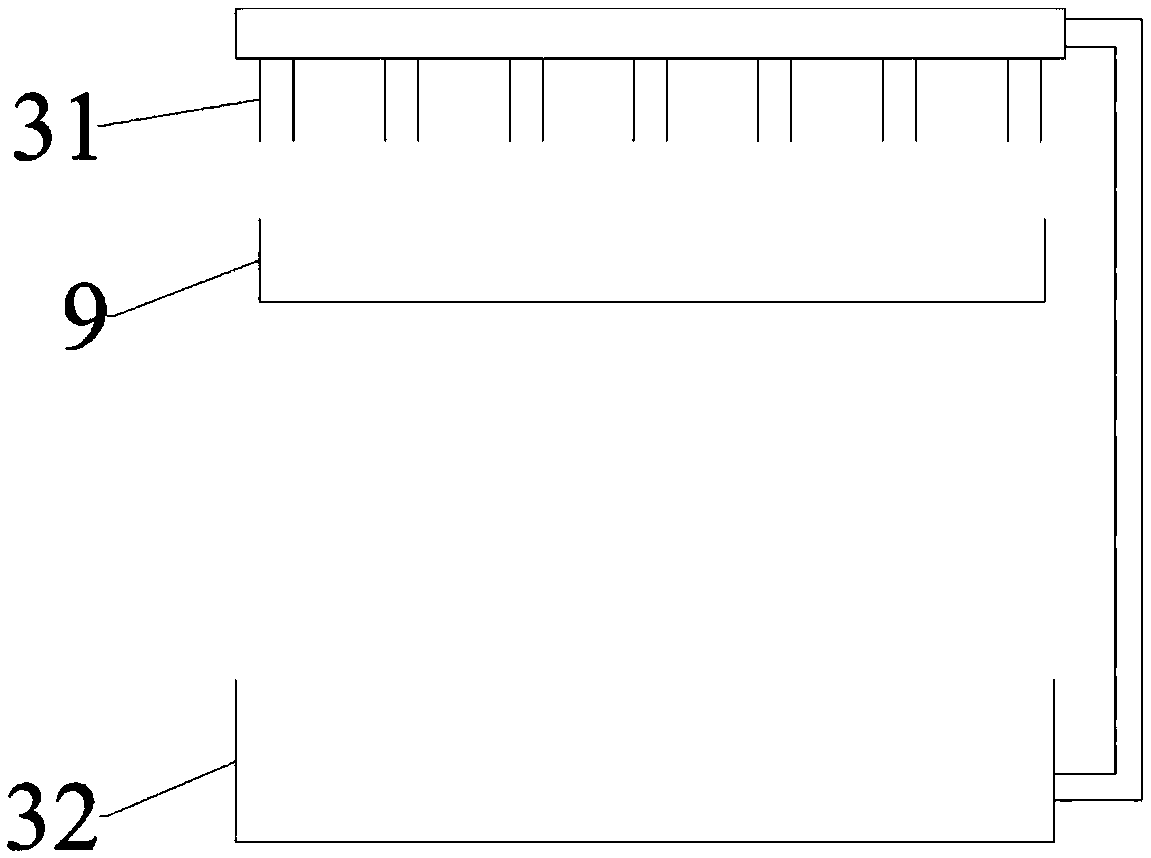

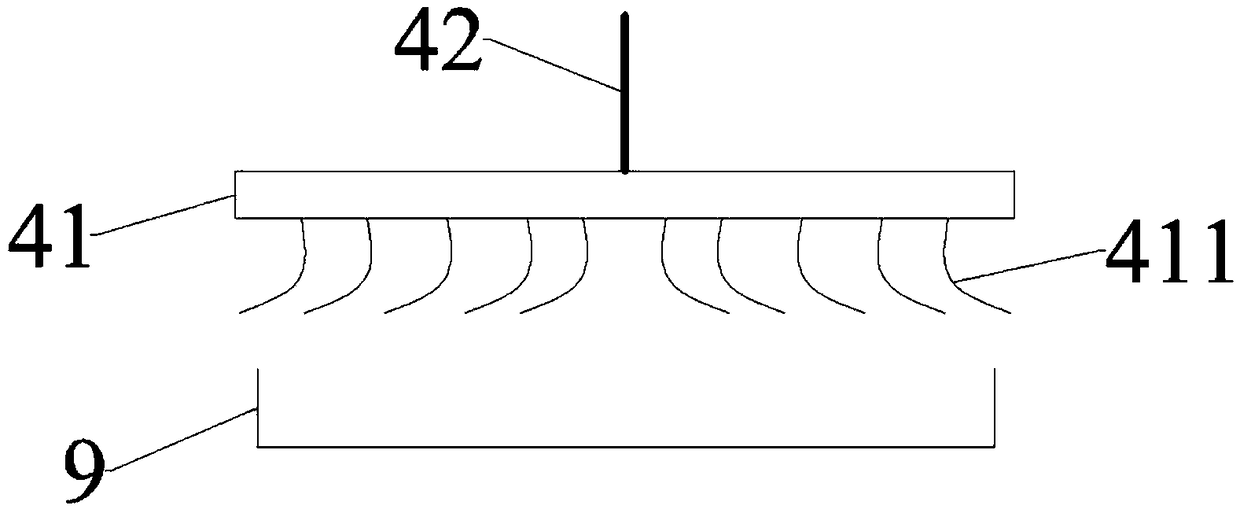

Fruit cleaning system

InactiveCN109007907APrevent drynessLittle artificial dependenceFood treatmentMotor driveElectric machinery

The invention discloses a fruit cleaning system. The fruit cleaning system comprises (1) a rotating mechanism, which comprises a motor, a rotating shaft and a rotating plate; the rotating shaft is vertically arranged, the rotating plate is circular, the rotating plate is horizontally arranged at the upper end of the rotating shaft, and the motor drives the rotating shaft to rotate; (2) a pluralityof clamping mechanisms, wherein the clamping mechanisms are uniformly arranged at the edge positions of the rotating plate; (3) a basket; (4) the flushing mechanisms, wherein the flushing mechanismsare uniformly distributed on the rotation path of the clamping mechanisms; (5) the brushing mechanisms, wherein the brushing mechanisms are uniformly distributed on the rotation path of the clamping mechanisms; (6) the rapping mechanisms, wherein the rapping mechanisms are uniformly distributed on the rotation path of the clamping mechanisms; (7) a blowing mechanism. In the invention, the rotatingmechanism is used for continuously feeding, cleaning and discharging, so that the dependence on the labor is small, the larger total volume of the fruits is divided into the small volume parts and placed in the baskets respectively, and then the flushing mechanism, the brushing mechanism and the rapping mechanism are used multiple times to improve the cleaning effect.

Owner:黄家寅

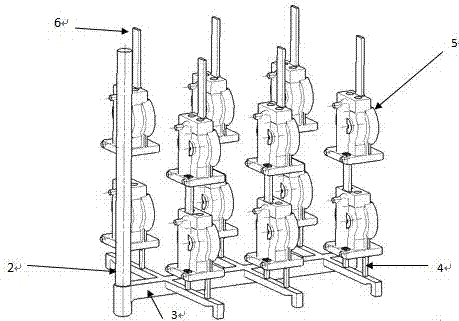

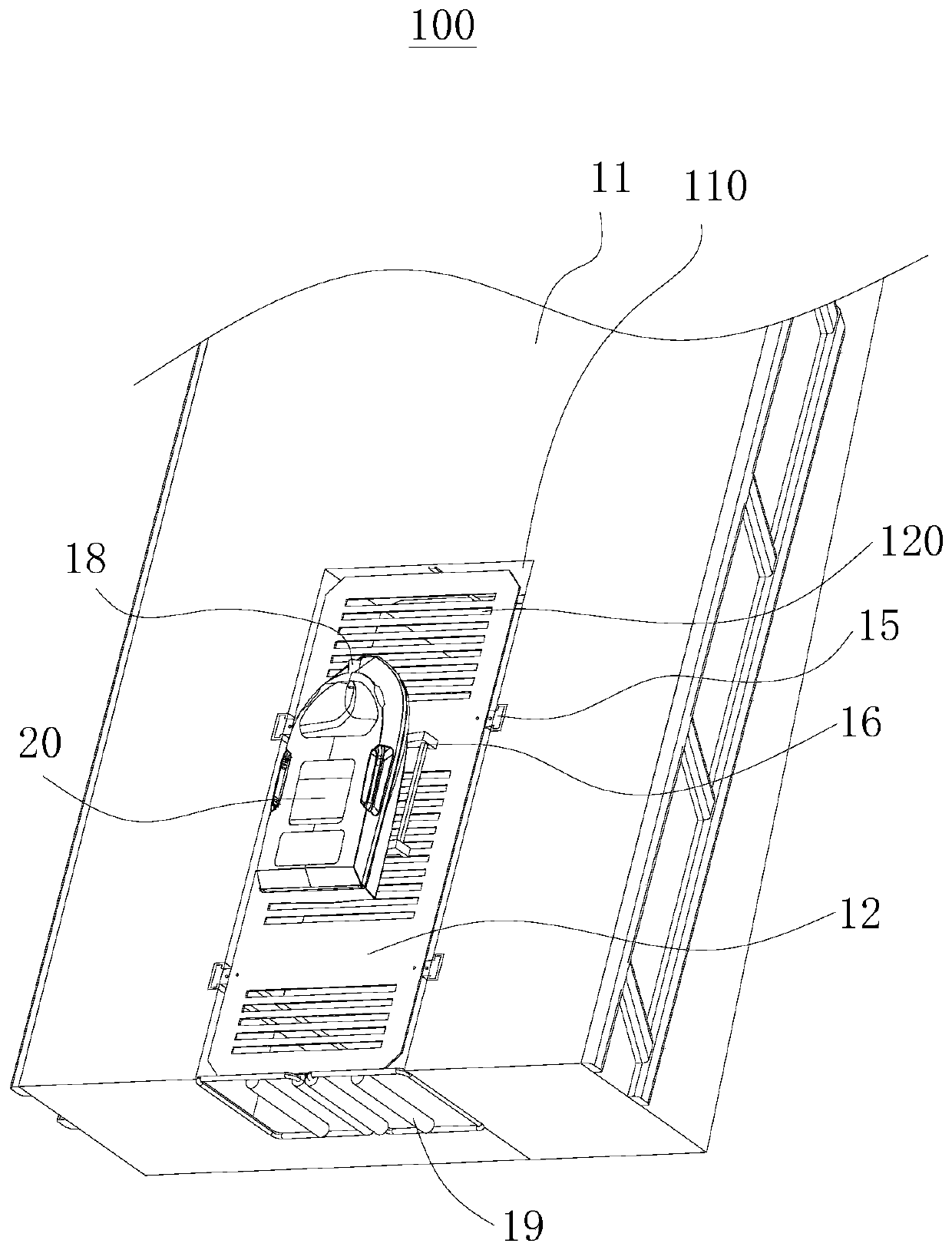

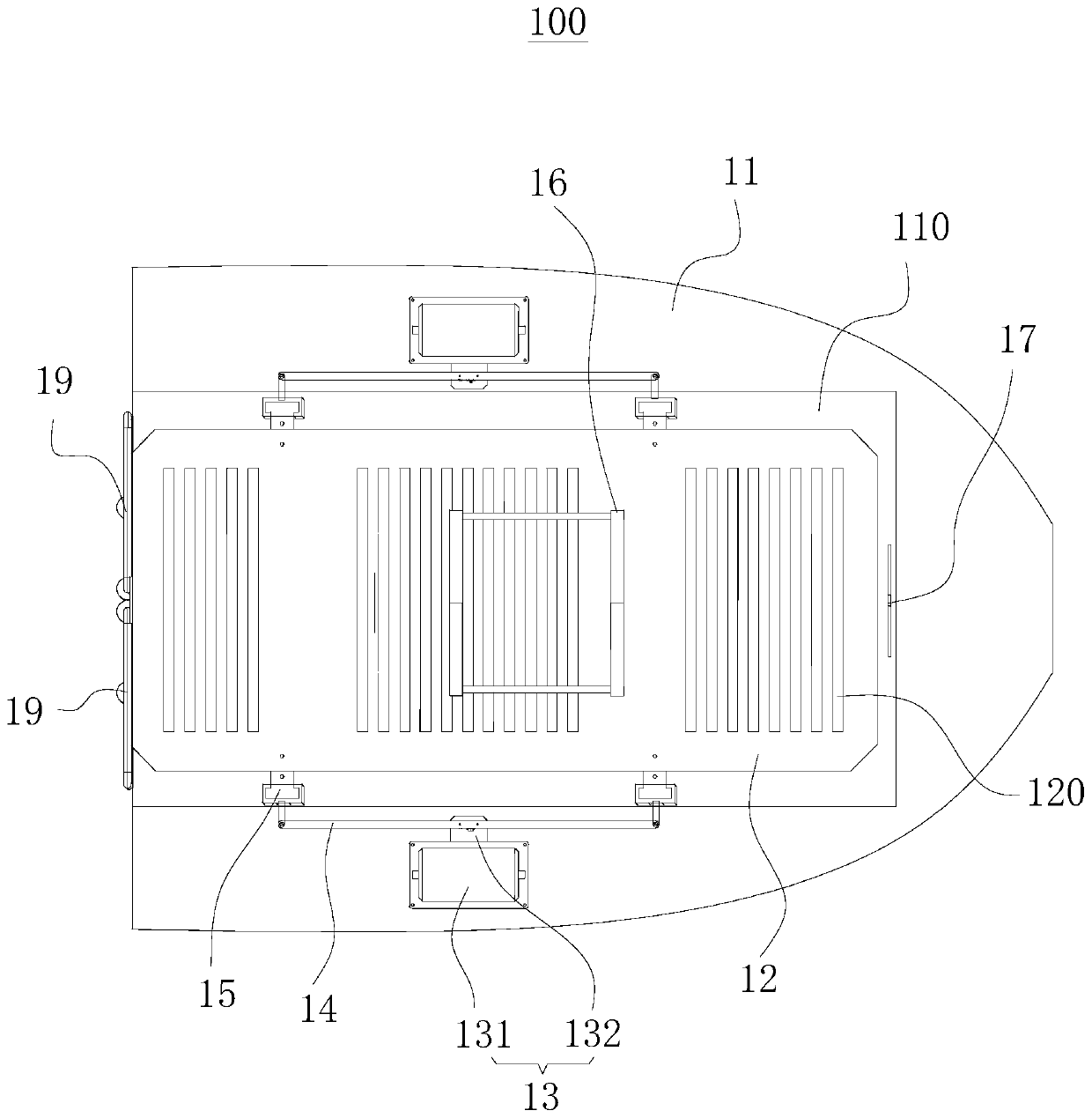

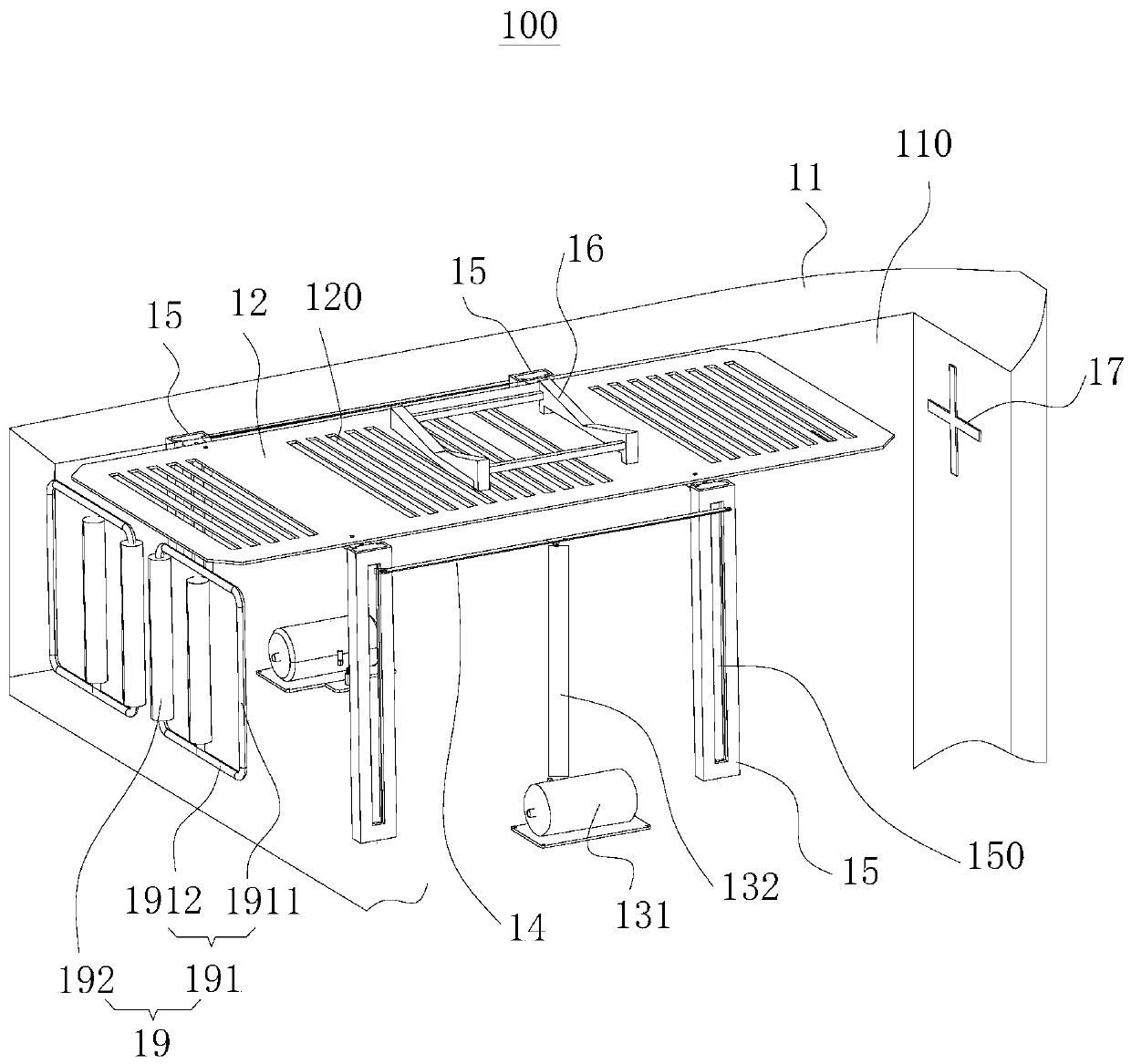

Unmanned navigation equipment recovering and releasing system

The invention belongs to the technical field of unmanned navigation equipment releasing and recovering devices, and provides an unmanned navigation equipment recovering and releasing system. The unmanned navigation equipment recovering and releasing system comprises a mother ship and a lifting platform, wherein a dock communicating with the water surface is formed on the side edge of the mother ship, and the lifting platform is arranged in the dock. The lifting platform can descend below the water surface and ascend above the water surface, the lifting platform is used for carrying unmanned navigation equipment and located in the dock, and therefore the lifting platform can be less influenced by stormy waves outside the mother ship, the shaking and fluctuating of the lifting platform can be reduced, and the collision risk between the unmanned navigation equipment and the lifting platform due to shaking is lower; and thus, the recovering and releasing of the unmanned navigation equipment can be effectively realized, and the unmanned navigation equipment recovering and releasing system is particularly suitable for terrible ocean environments, is simple in operation and low in labor dependence and can ensure the safety of the unmanned navigation equipment and prevent the unmanned navigation equipment from damage.

Owner:ZHUHAI YUNZHOU INTELLIGENCE TECH COMPANY +1

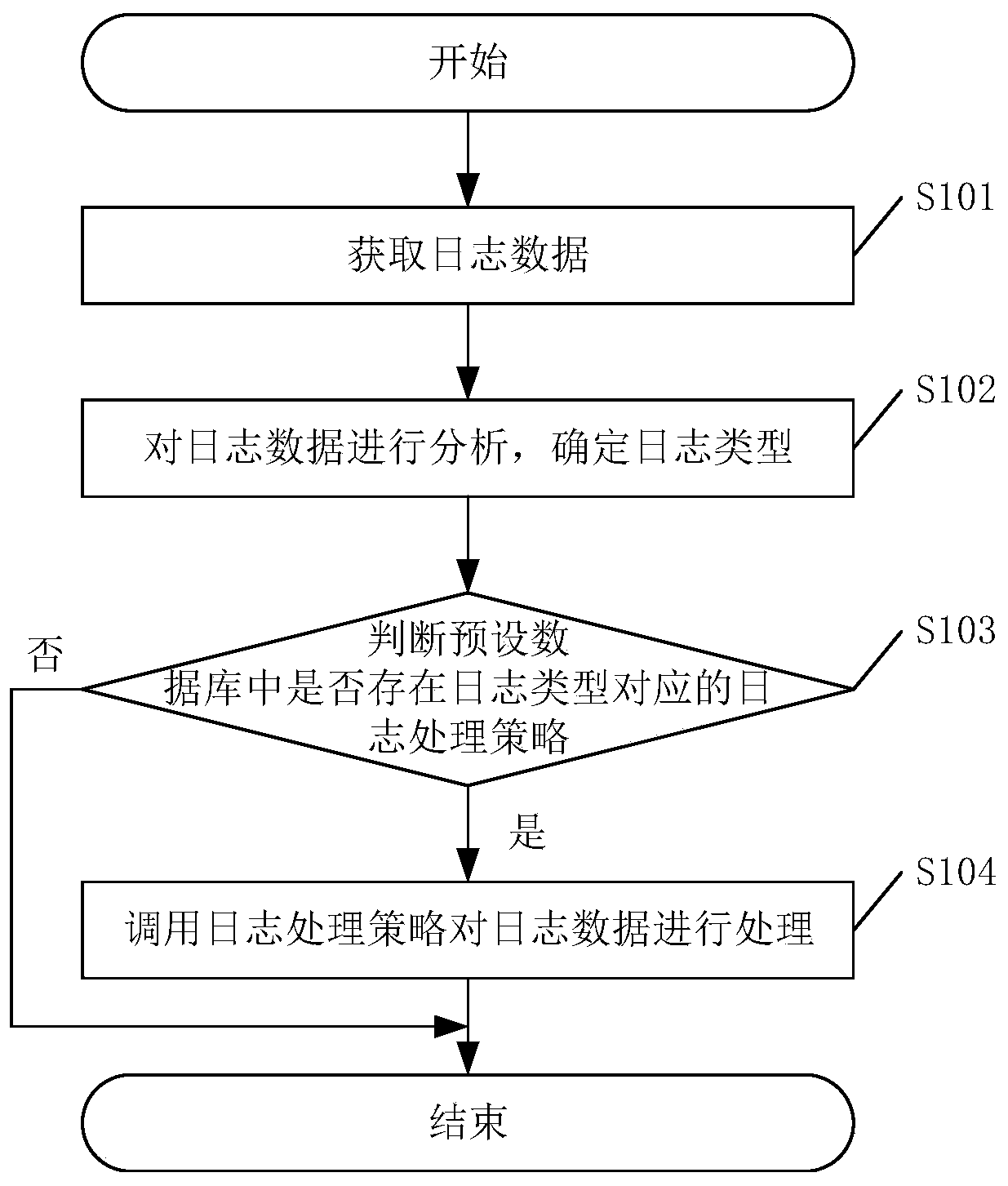

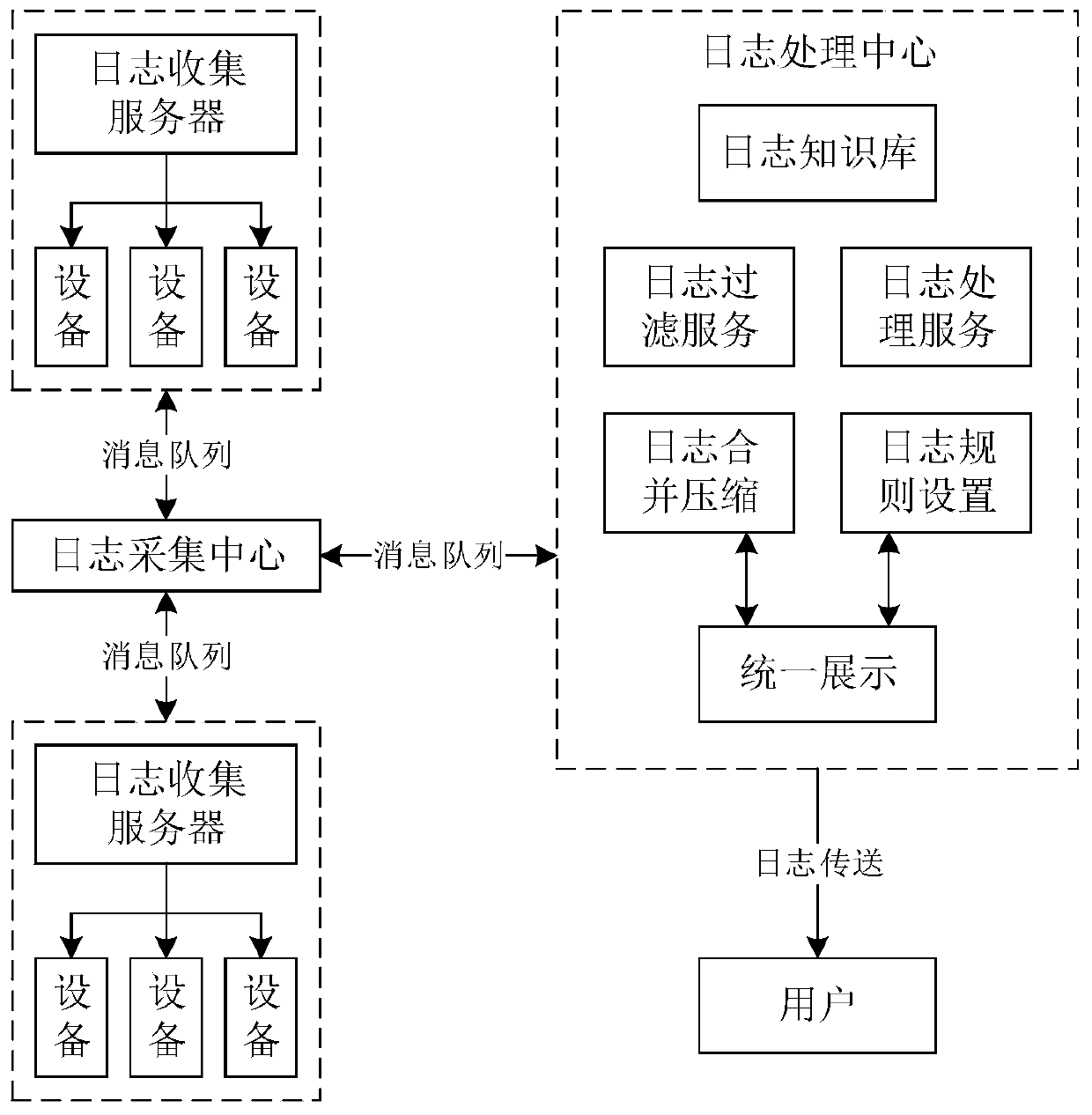

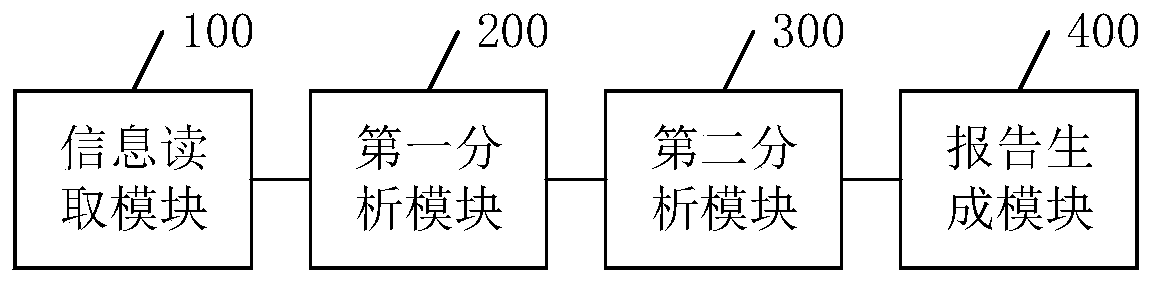

Log processing method, device and equipment and storage medium

InactiveCN111124859AImprove log processing efficiencyLittle artificial dependenceHardware monitoringData miningOperations research

The invention discloses a log processing method. The method comprises the steps of obtaining log data; analyzing the log data, and determining a log type; judging whether a log processing strategy corresponding to the log type exists in a preset database or not; if so, calling the log processing strategy to process the log data; according to the log processing method, the log data is effectively managed, and the log processing efficiency is improved while the error rate is reduced. The invention furthermore discloses a log processing device and equipment, and a computer readable storage medium, which all have the above beneficial effects.

Owner:北京浪潮数据技术有限公司

Manufacturing method for composite light filling component

A manufacturing method for a composite light filling component comprises the steps as follows: prefabricating a light internal mold; buckling the light internal mold; fixing the light internal mold; making a mixture of cement, mortar and glue; performing surface pretreatment, that is, spreading the mixture of the cement, the mortar and the glue, which is stirred well and in a semifluid state, onto the upper surface of the light internal mold; wrapping the light internal mold with a fiberglass mesh; performing surface treatment, that is, spreading the mixture of cement, mortar and glue, which is in the semifluid state, onto the lower surface and the peripheral side surface of the light internal mold to cover the fiberglass mesh; performing curing, that is, turning over the light internal mold after the mixture of the cement, the mortar and the glue on the lower surface is solidified and cured, and finally enabling the mixture of the cement, the mortar and the glue to form a hard inorganic composite layer on the outer surface of the light internal mold. The manufacturing method for the composite light filling component, provided by the invention, is simple, fast and reasonable in technological process; the composite light filling component manufactured according to the manufacturing method is reasonable in product structure, convenient for production and transportation and convenient and fast in construction.

Owner:刘青云

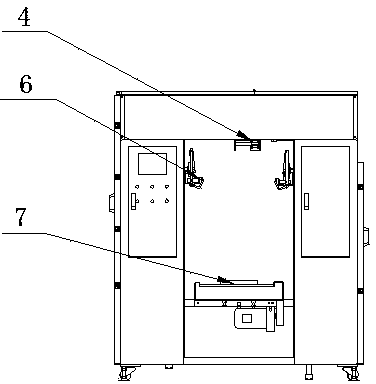

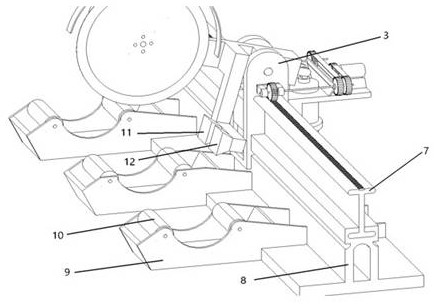

Double-layer bagging equipment in carton

The invention discloses double-layer bagging equipment in a carton. The double-layer bagging equipment in the carton comprises a main frame body, a film storage frame, a film sending mechanism, a plastic film clamping mechanism, a cutoff mechanism, a package conveyor and a film guide mechanism, wherein the film storage frame is installed on the lower part of one side of the main frame body; the film sending mechanism is installed above the film storage frame; the main frame body spans above the package conveyor; the package conveyor is arranged in the main frame body and penetrates through the inside of the main frame body; the plastic film clamping mechanism, the cutoff mechanism and the film guide mechanism are respectively fixedly arranged on the main frame body; the front end of the plastic film clamping mechanism is provided with a sucking disc; the upper side of the plastic film clamping mechanism is provided with a hot-melting plate; the cutoff mechanism is installed on the upper side of the hot-melting plate; the film guide mechanism is installed on the lower side of the plastic film clamping mechanism; the film guide mechanism is provided with a film blowing pipe. The double-layer bagging equipment in the carton, which is disclosed by the invention, has the advantages of simple and reasonable structure, excellent effect in the practical application, stable mechanical performance, low operation cost, high automatic control degree, simplicity in operation, small dependence on manpower and high working efficiency, and other complex mechanisms and elements are not required.

Owner:DALIAN JIALIN EQUIP MFG

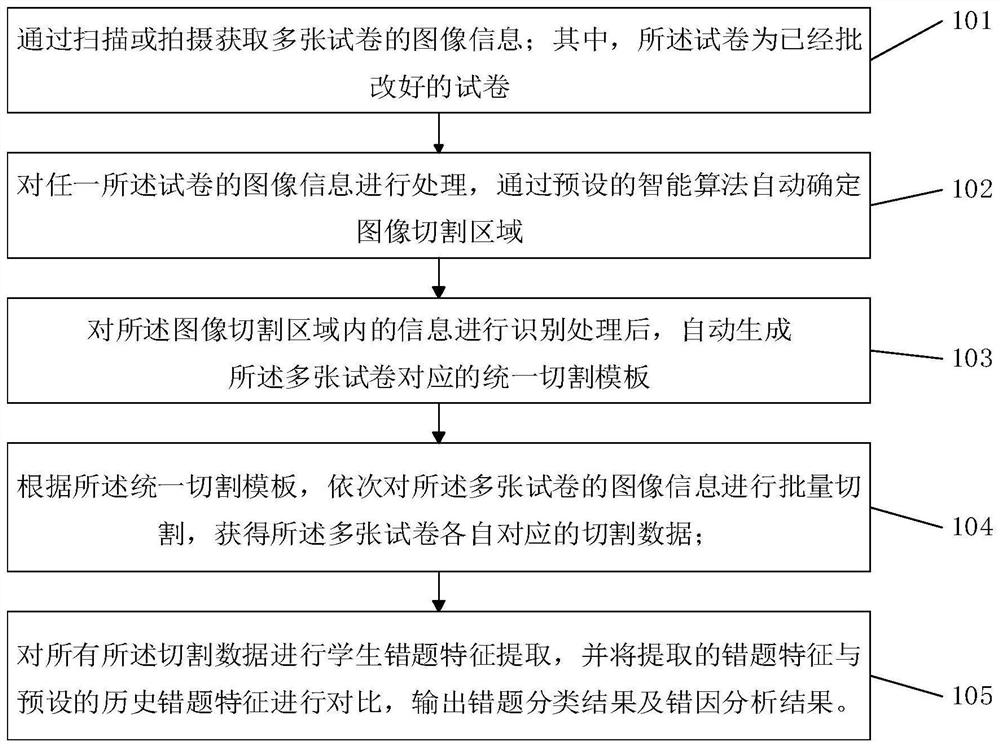

Intelligent test paper cutting method and system and storage medium

PendingCN113205527AImplement classificationLittle artificial dependenceImage analysisCharacter and pattern recognitionFeature extractionAlgorithm

The invention discloses an intelligent test paper cutting method and system and a storage device. The method comprises the following steps: acquiring image information of a plurality of test papers through scanning or shooting, wherein the test paper is corrected test paper; processing the image information of any test paper, and automatically determining an image cutting area through a preset intelligent algorithm; after information in the image cutting area is recognized and processed, forming a unified cutting template corresponding to the multiple pieces of test paper automatically; according to the unified cutting template, sequentially performing batch cutting on the image information of the multiple pieces of test paper to obtain cutting data corresponding to the multiple pieces of test paper; and performing student error question feature extraction on all the cut data, comparing the extracted error question features with preset historical error question features, and outputting an error question classification result and an error cause analysis result. The test paper image information is automatically cut and classified through an intelligent algorithm, the manual dependence is reduced, the time is saved, and the efficiency of score recording, wrong question collection and corresponding statistical analysis is improved.

Owner:广州远大信息发展有限公司

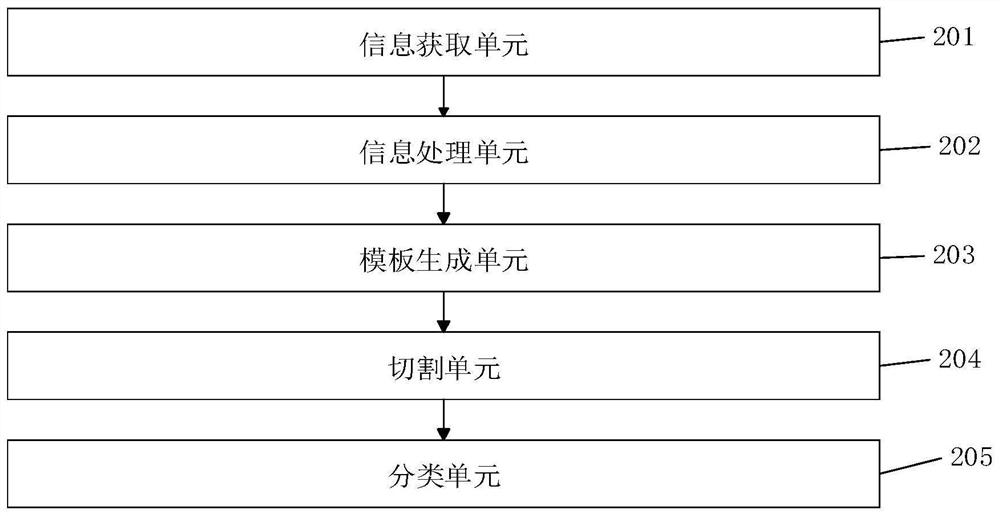

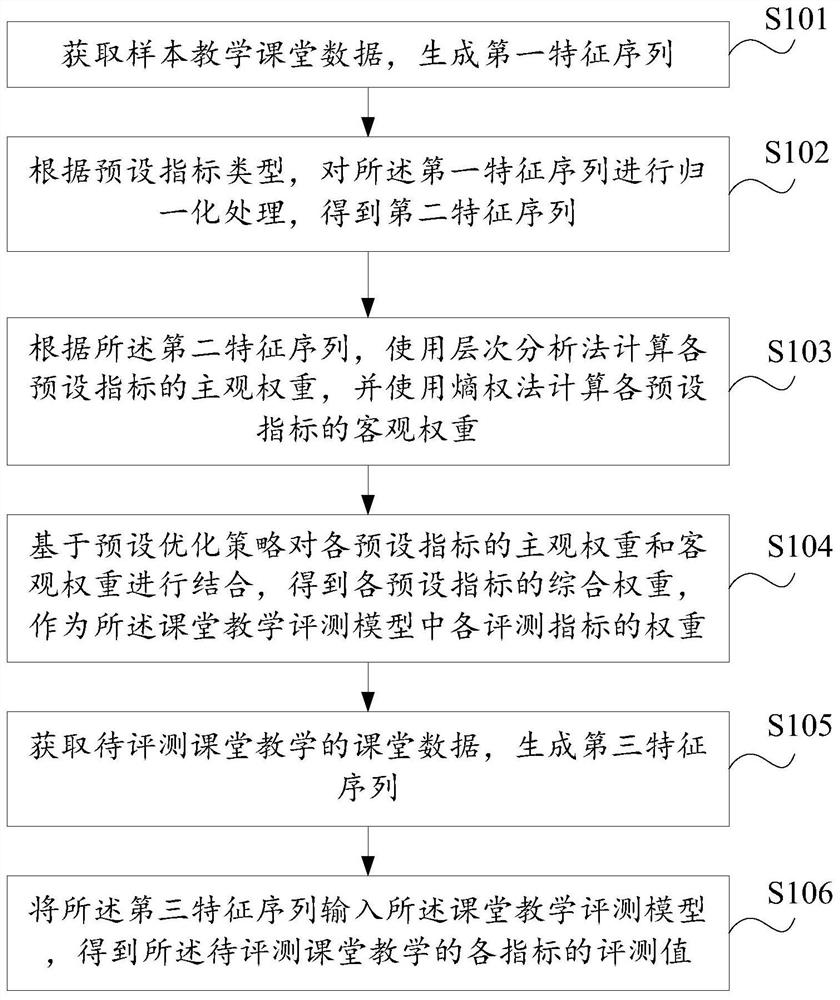

Classroom teaching evaluation method based on combined weighting method

PendingCN113408957ALittle artificial dependenceImprove effectiveness and reliabilityCharacter and pattern recognitionResourcesData scienceData input

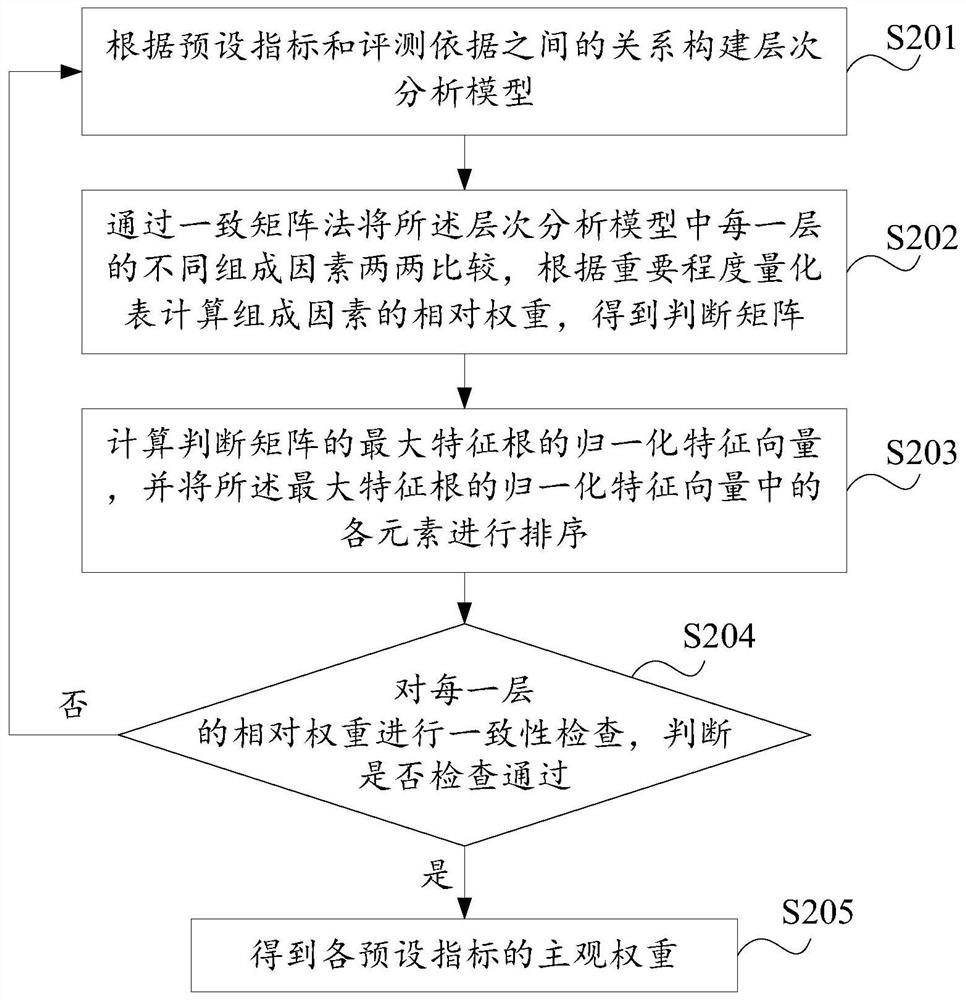

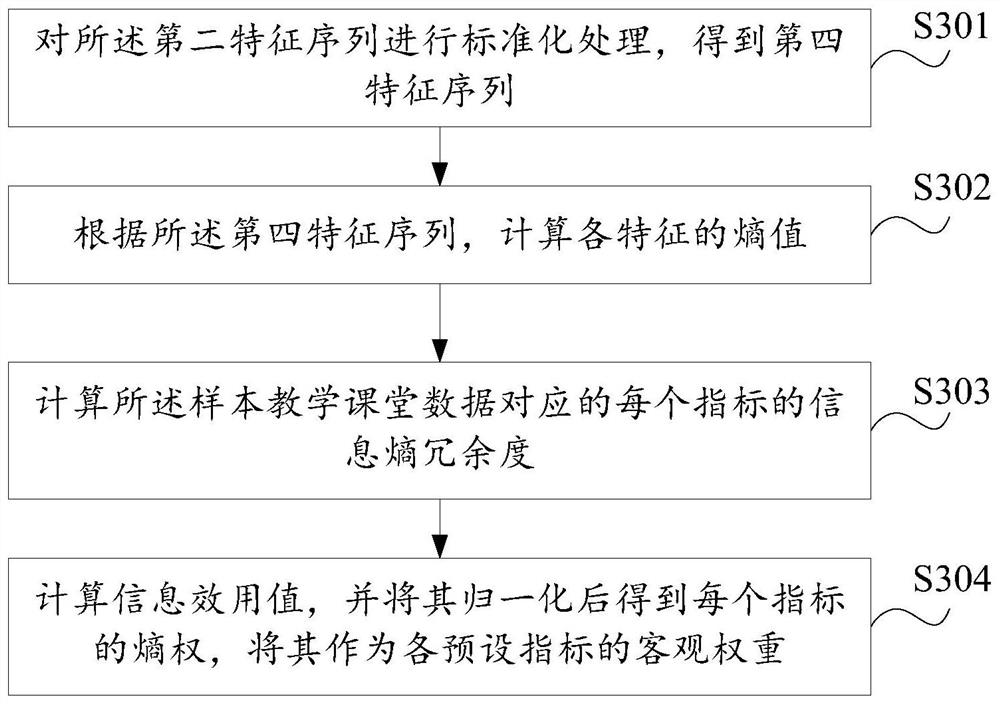

The invention provides a classroom teaching evaluation method based on a combined weighting method, and belongs to the technical field of intelligent education. The method comprises the following steps: acquiring sample teaching classroom data, and generating a first feature sequence; according to a preset index type, performing normalization processing on the first feature sequence to obtain a second feature sequence; according to the second feature sequence, using an analytic hierarchy process to calculate the subjective weight of each preset index, and using an entropy weight method to calculate the objective weight of each preset index, wherein the preset index is an output parameter of a preset classroom teaching evaluation model; combining the subjective weight and the objective weight of each preset index based on a preset optimization strategy to obtain a comprehensive weight of each preset index; obtaining classroom data of to-be-evaluated classroom teaching; and inputting the to-be-evaluated classroom data into the classroom teaching evaluation model to obtain an evaluation value of each index of the to-be-evaluated classroom teaching. Effective information in the subjective weight and the objective weight is considered, and the effectiveness and the reliability of the evaluation result are high.

Owner:BEIJING NORMAL UNIVERSITY

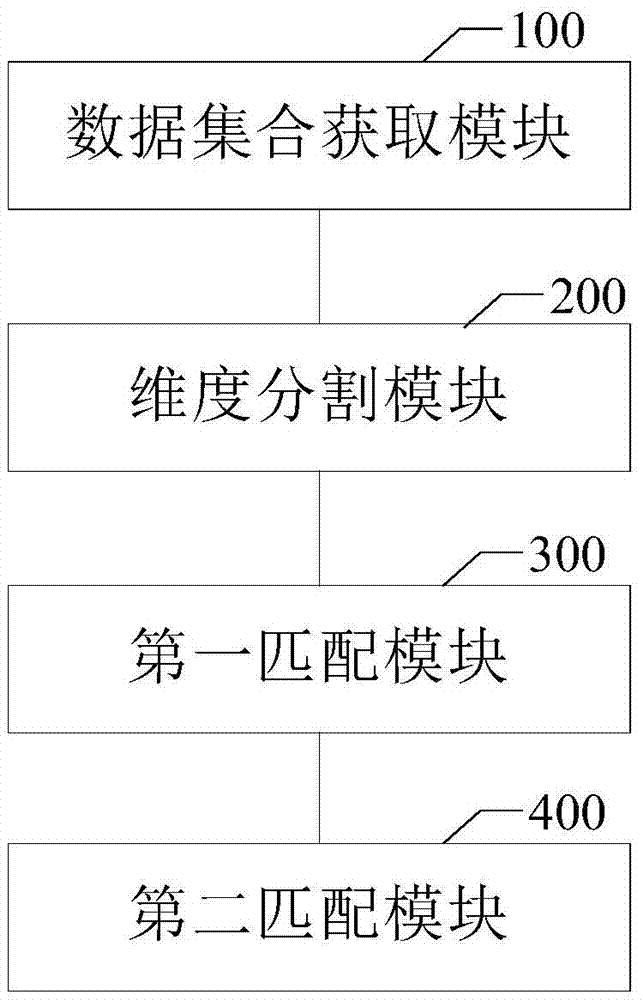

Data matching method and data matching device

ActiveCN106934409ALittle artificial dependenceShort timeCharacter and pattern recognitionData matchingData mining

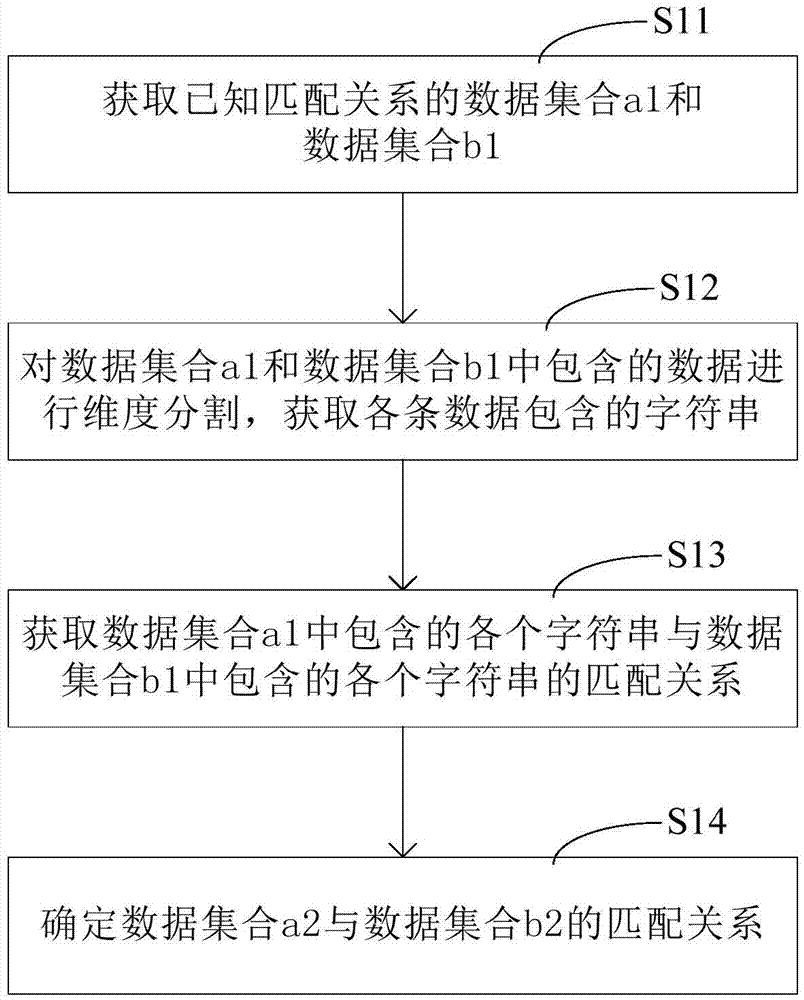

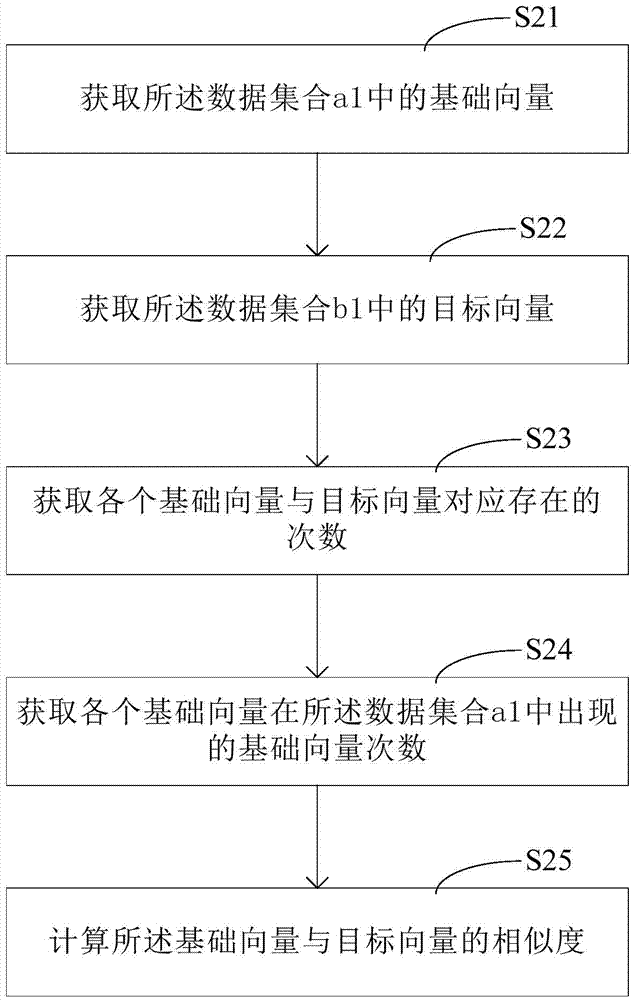

The invention discloses a data matching method and a data matching device. In the method, a data set a1 and a data set b1 with a known matching relationship are firstly acquired; part or all of character string types contained in a to-be-matched data set a2 belong to character string types contained in the data set a1; part or all of character string types contained in a to-be-matched data set b2 belong to character string types contained in the data set b1; the character string for each piece of data in the a1 and the b1 is then acquired, and the matching relationship between each character string in the data set a1 and each character string in the data set b1 is acquired; and then, according to the matching relationship, the matching relationship between the data set a2 and the data set b2 is determined. The scheme of the invention can determine the matching relationship between two to-be-matched data sets, manual dependence is low, matching is realized according to correlation between character strings in the data sets, manual selection condition setting and comparison according to the selection condition are not needed, and in comparison with the prior art, the consumed time is short, and the matching efficiency is improved.

Owner:YOUXINPAI BEIJING INFORMATION TECH CO LTD

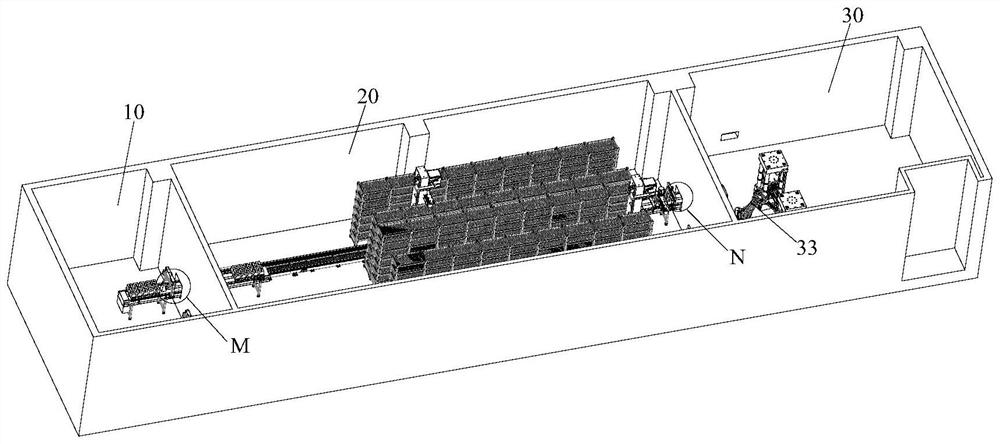

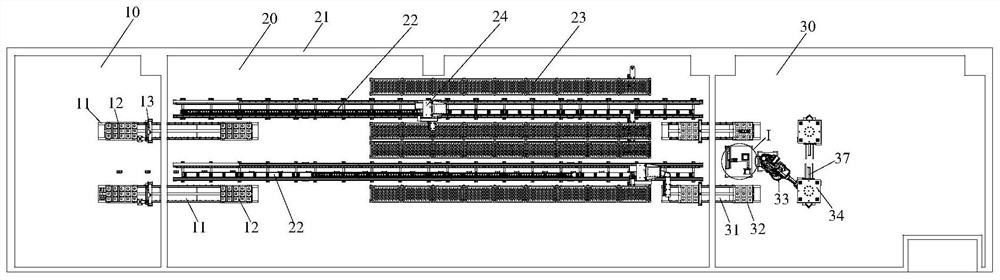

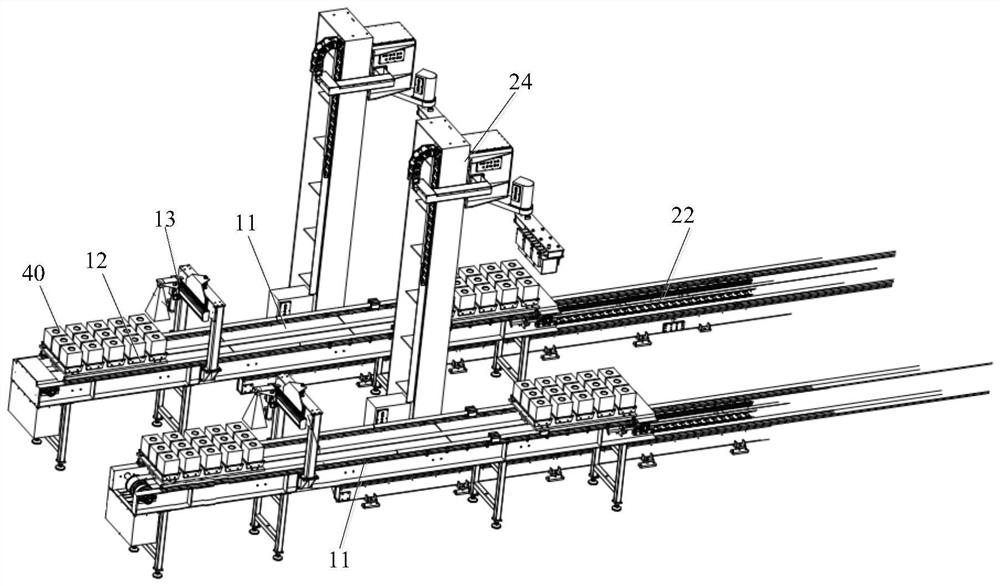

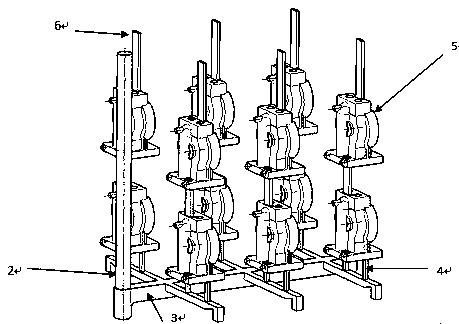

Full-automatic intelligent maintenance and strength detection system for concrete test blocks

PendingCN114858555ARealize automatic maintenanceGuarantee the quality of maintenanceConveyorsPreparing sample for investigationThe InternetMachine

The invention provides a full-automatic intelligent maintenance and strength detection system for concrete test blocks. The full-automatic intelligent maintenance and strength detection system comprises a warehousing unit, a maintenance unit and a compression resistance testing unit. The warehousing unit comprises a first conveying line, a first tray and a code spraying / scanning assembly; the maintenance unit comprises a maintenance bin, a track, a maintenance frame and a stacking machine. According to the system, by adopting the technical means of an image recognition technology, the Internet of Things, automation, intelligent control, a robot and the like, the concrete test blocks can be automatically maintained and conveyed, and after compression resistance test units are integrated, the concrete test blocks can be automatically detected, so that the integration, automation and intelligentization of the concrete test block maintenance and strength detection process are realized, and the working efficiency is improved. The maintenance quality of the concrete test block is guaranteed, the detection process is managed and protected more finely, the detection efficiency is greatly improved, the detection quality is guaranteed, and the manual dependence is reduced.

Owner:中钢集团郑州金属制品研究院股份有限公司

Manufacturing method for split-type lightweight filling component

The invention discloses a manufacturing method for a split-type lightweight filling component. The manufacturing method comprises the following steps: prefabricating a lightweight inner mold; mixing a mixture of cement, mortar and glue; performing surface pretreatment, coating the upper surfaces of polystyrene box bodies with the mixed mixture of the cement, the mortar and the glue in a semi-fluid state; wrapping a fiber glass net; performing surface treatment, coating the peripheral side surfaces of each polystyrene box body with the mixture of the cement, the mortar and the glue in the semi-fluid state; covering the fiber glass net; hardening and curing; splitting the lightweight inner mold, aligning the positions of the lower surfaces of the two hardened and cured polystyrene box bodies, bundling the two hardened and cured polystyrene box bodies in a crossed way by using a plastic tape, and tightening a locking buckle on the plastic tape to split a complete split-type lightweight filling component. The manufacturing method for the composite lightweight filling component disclosed by the invention has the advantages that the simple, convenient and reasonable process flow is realized; a composite lightweight filling component product produced by the manufacturing method is reasonable in structure, convenient to produce and transport, and convenient to construct.

Owner:刘青云

Emptying device

PendingCN111379306AReduce shockExtended emptying pathFatty/oily/floating substances removal devicesSewerage structuresRain fallEngineering

The invention discloses an emptying device comprising an emptying pipe, a filter piece and a protection cover. An emptying passageway used for discharging first rain is arranged in the emptying pipe.The emptying pipe is arranged in a flow abandoning device in a penetrating manner and fixed in the flow abandoning device. The filter piece is arranged on the emptying pipe in a sleeving manner and fixed to the emptying pipe. The protection cover is arranged on the emptying pipe and the filter piece in a covering manner. When the first rain falls into the flow abandoning device, due to the covering arrangement of the protection cover, the emptying pipe and the filter piece are sheltered from the first rain, the emptying pipe and the filter piece can be protected by the protection cover, the flow direction of the first rain can also be changed, the emptying route of the first rain is lengthened, and the impact of the first rain on the filter piece and the emptying pipe is reduced; the situation that part of pollutant is extremely likely to sink to the bottom of the flow abandoning device under the effect of the gravity of itself and it is avoided that the emptying pipe is blocked can happen, the situation that the other part of the pollutant is under the effect of the filter piece and it is avoided that the emptying pipe is blocked can also happen, and therefore the emptying efficiency and the emptying effect are ensured, dependence on manual work is small, and automatic emptying of the first rain can be achieved.

Owner:BEIJING WATER SCI & TECH INST

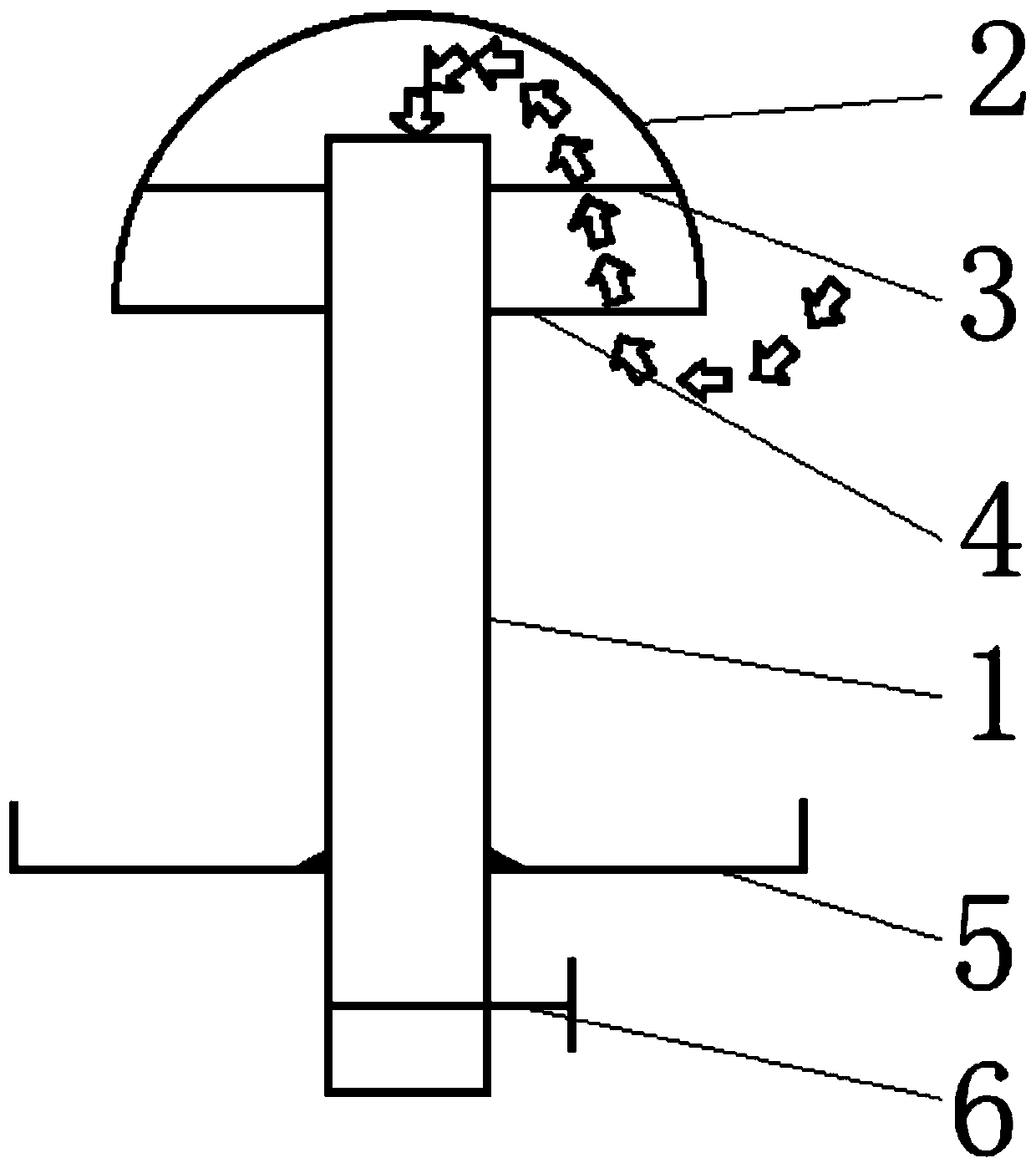

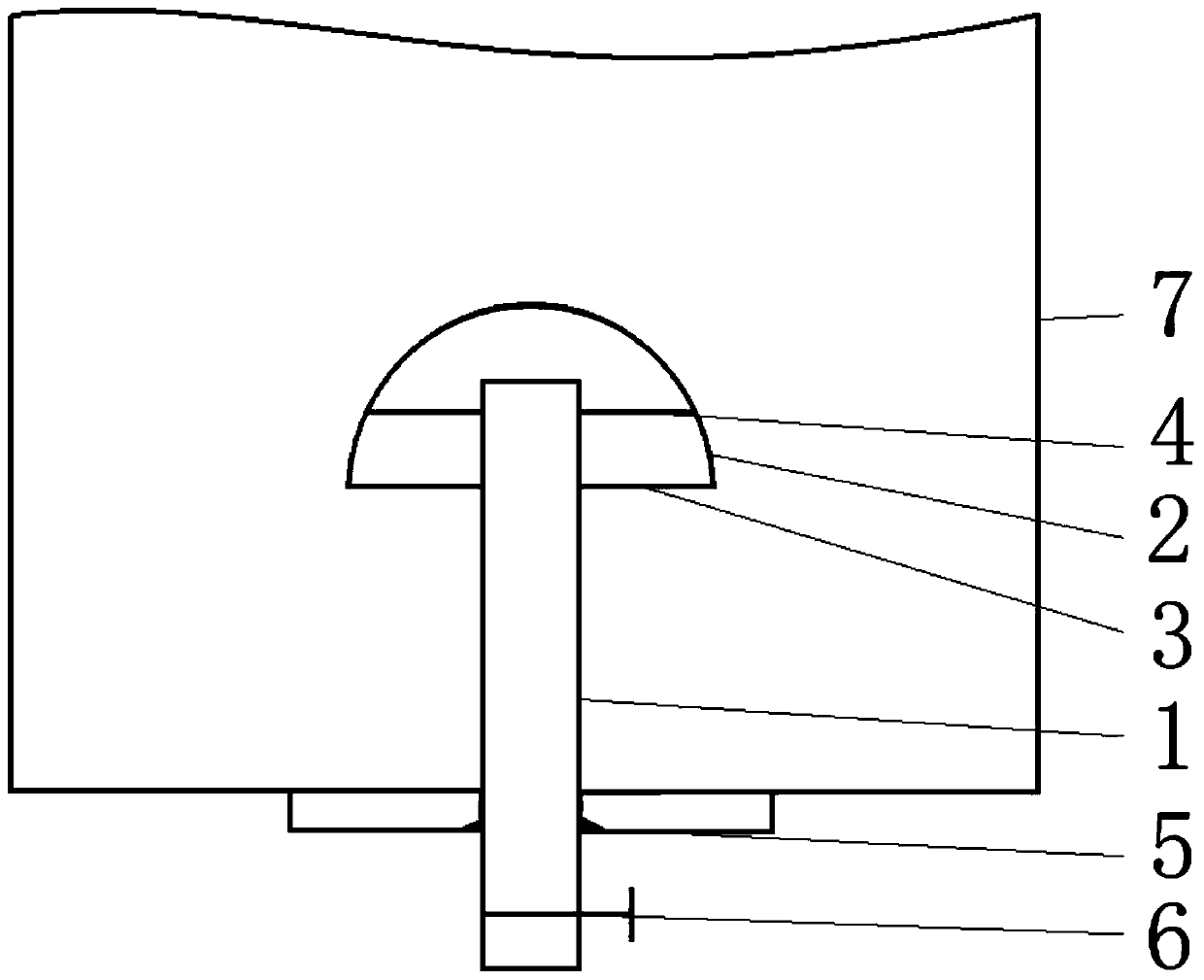

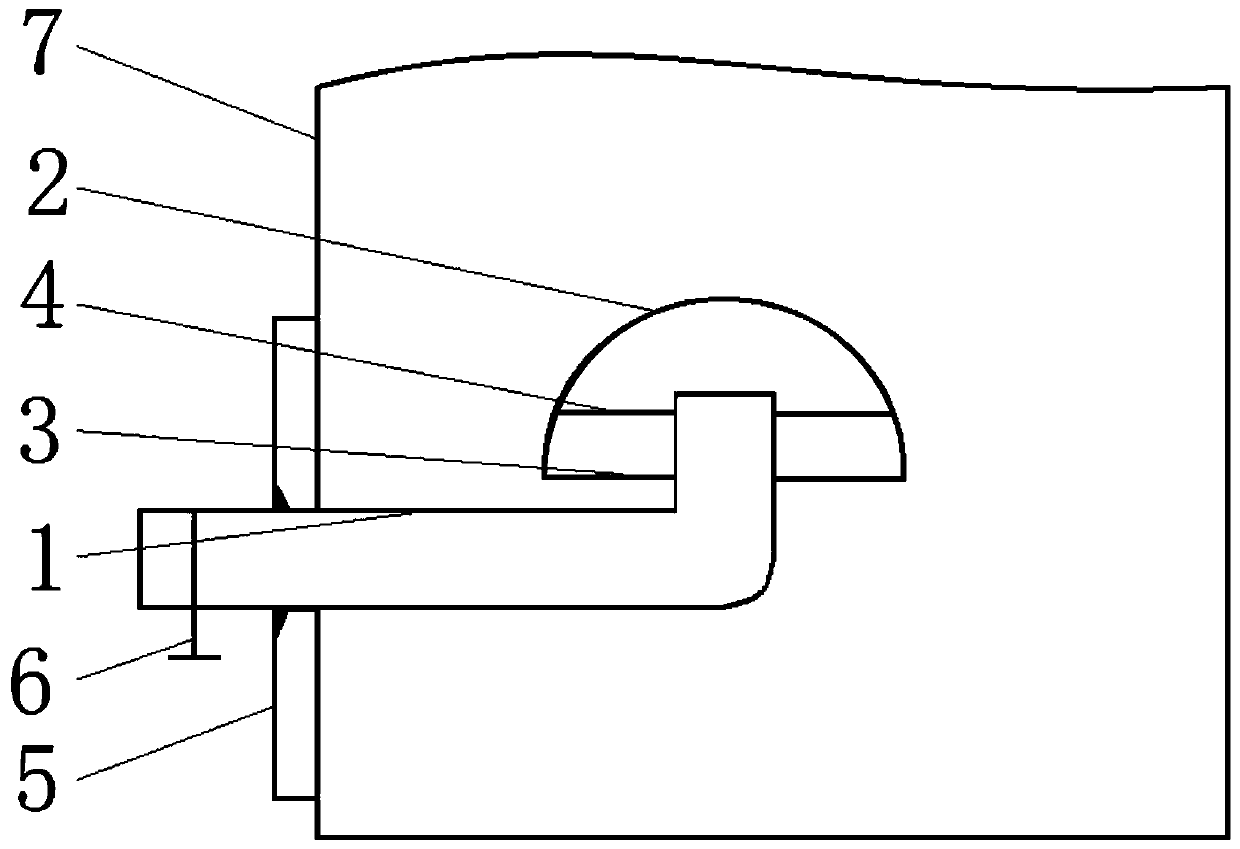

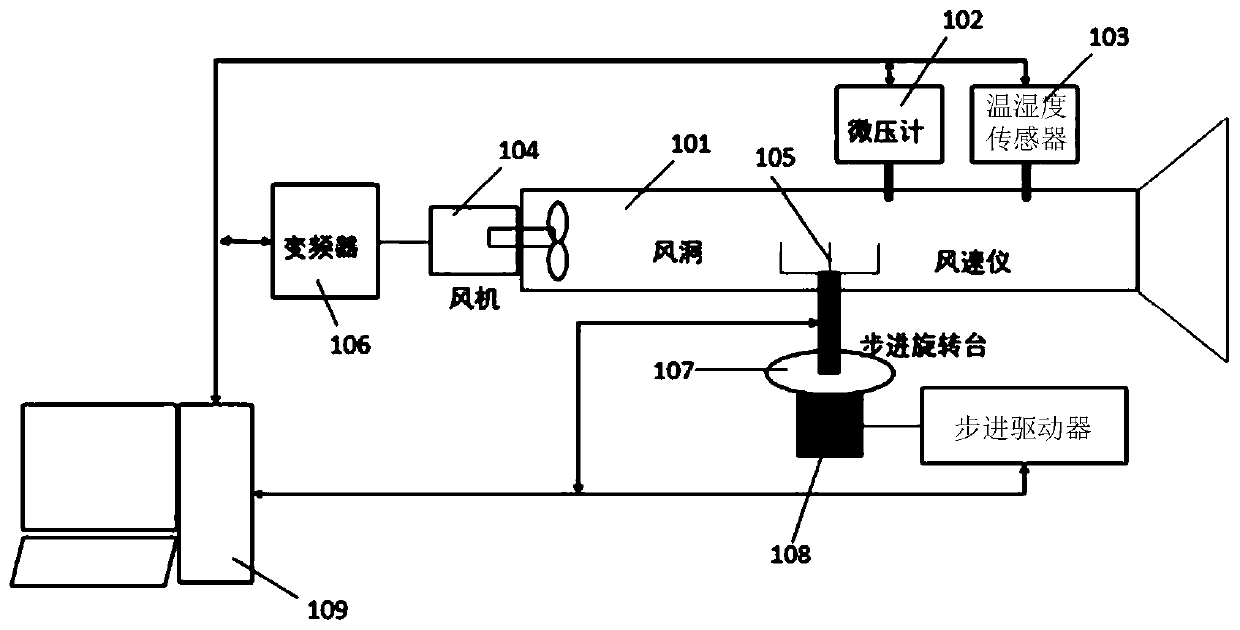

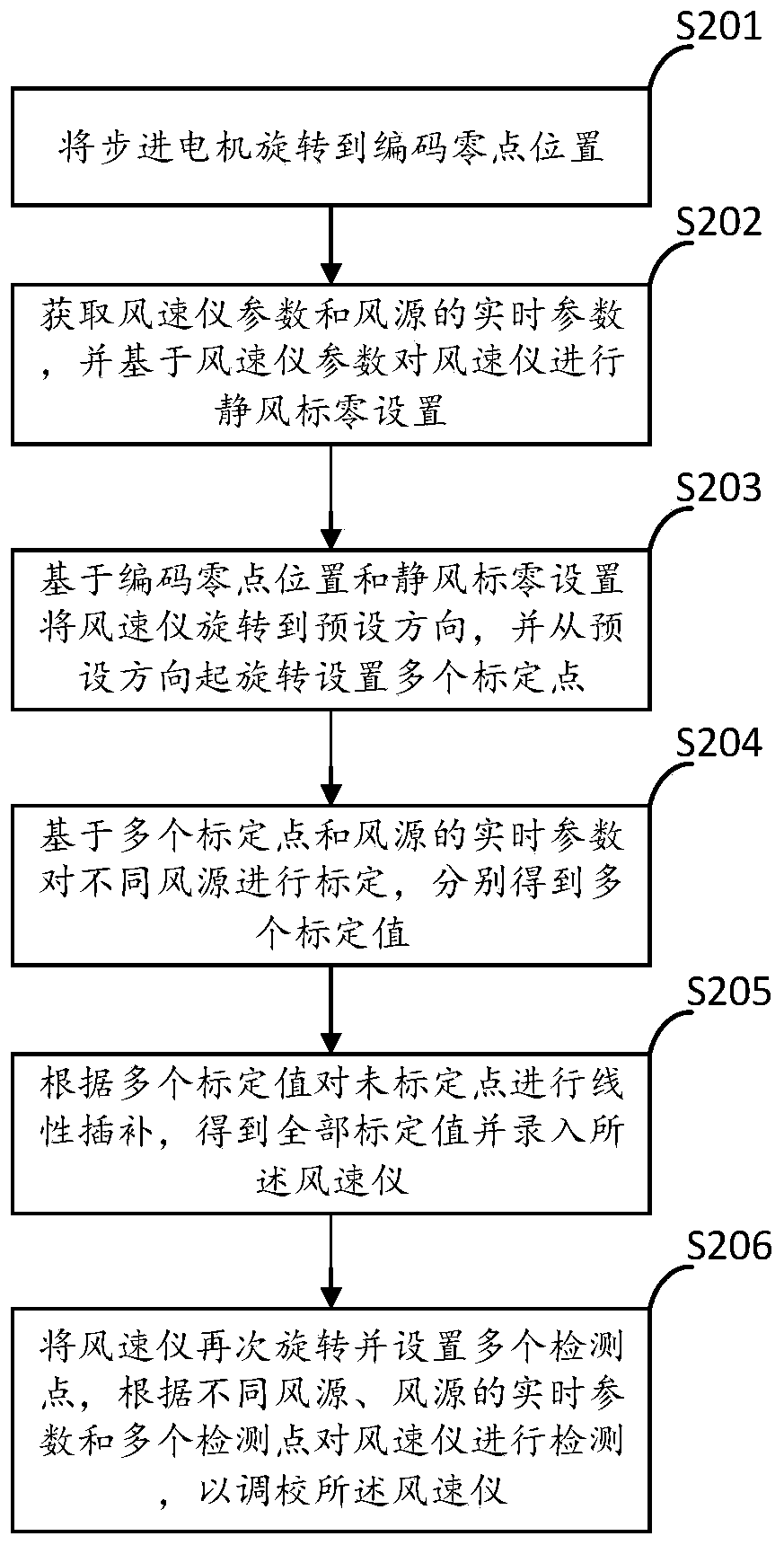

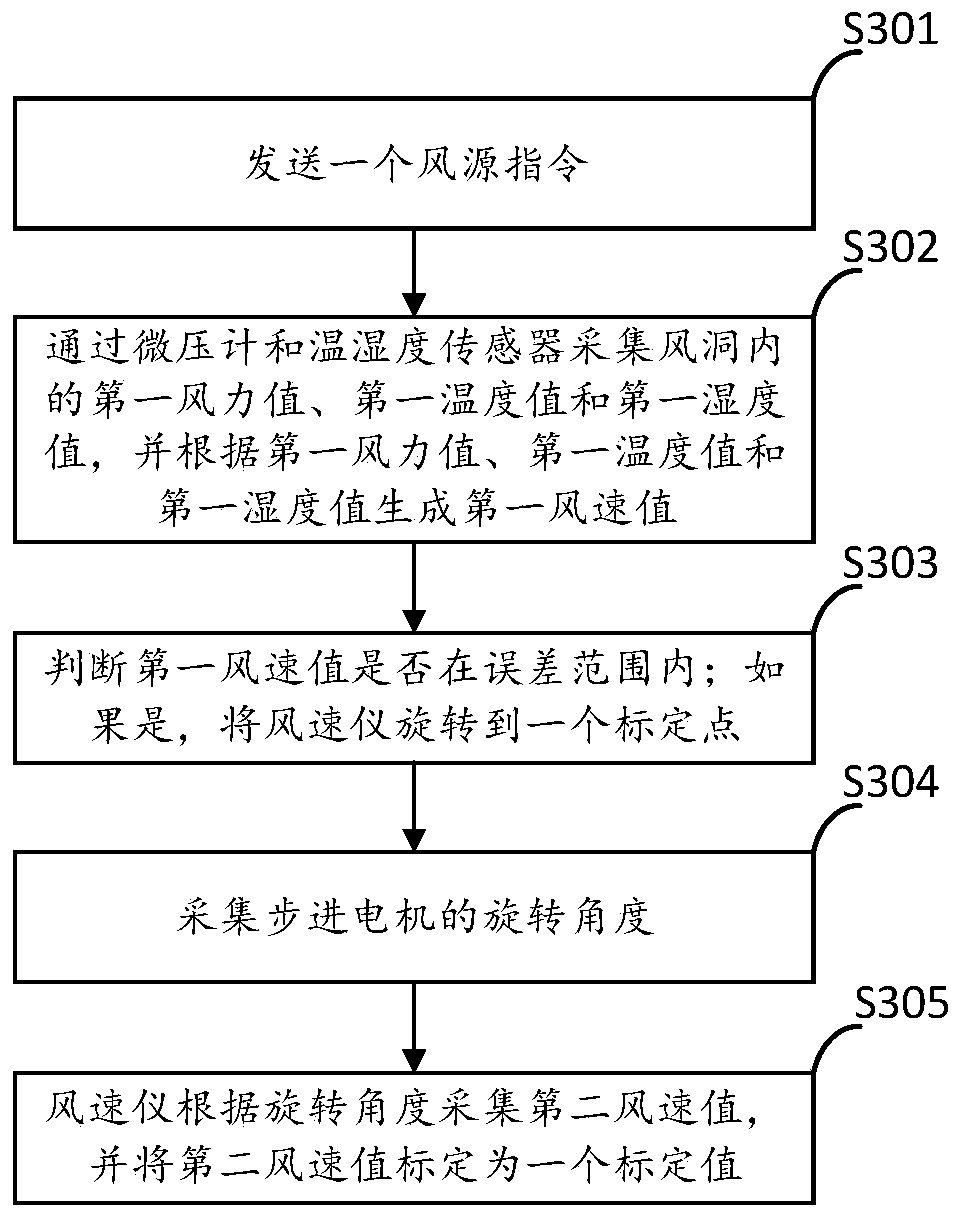

Anemograph adjusting device and method and electronic equipment

ActiveCN110927408ALittle artificial dependenceReduce error rateTesting/calibration of speed/acceleration/shock measurement devicesFrequency changerThermodynamics

The invention provides an anemograph adjustment device and method and electronic equipment, and relates to the technical field of anemograph adjustment. The anemograph adjustment device comprises a wind tunnel, and a micromanometer, a temperature and humidity sensor, a fan and an anemograph which are arranged in the wind tunnel; the fan is also connected with the frequency converter; the anemograph is connected with a stepping rotary table, and the stepping rotary table is provided with a stepping motor and a stepping driver which are connected with each other; and the anemograph, the micromanometer, the temperature and humidity sensor, the frequency converter and the stepping driver are all connected with the controller. The stepping driver is used for rotating the stepping motor to a coding zero point position according to a zero point instruction sent by the controller; the fan rotates to provide a wind source for the wind tunnel; the micromanometer and the temperature and humiditysensor are used for acquiring real-time parameters of the air source; the stepping motor controls the anemograph to rotate; and the controller performs static wind indicator zero setting on the anemograph, and performs calibration, linear interpolation and detection on the anemograph based on the encoding zero position and the static wind indicator zero setting so as to adjust the anemograph. Theadjustment and calibration efficiency can be effectively improved, and the error rate can br effectively reduced.

Owner:SHANGHAI NANHUA ELECTRONICS

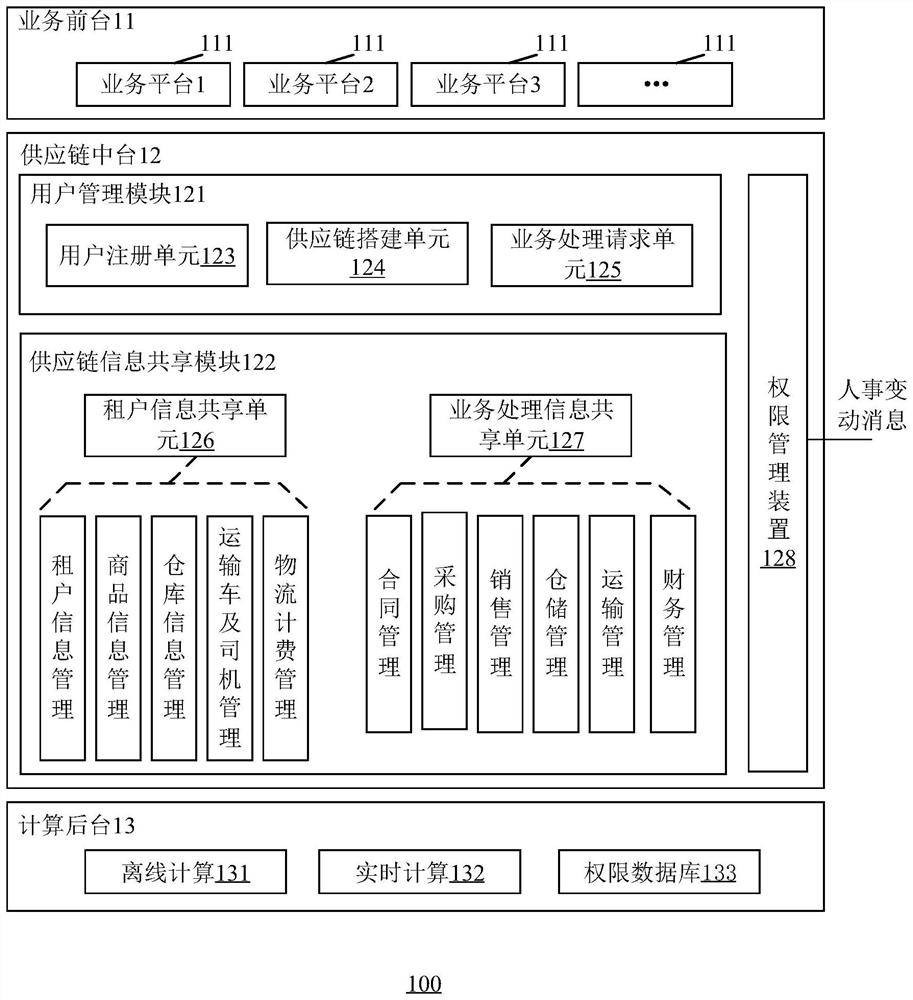

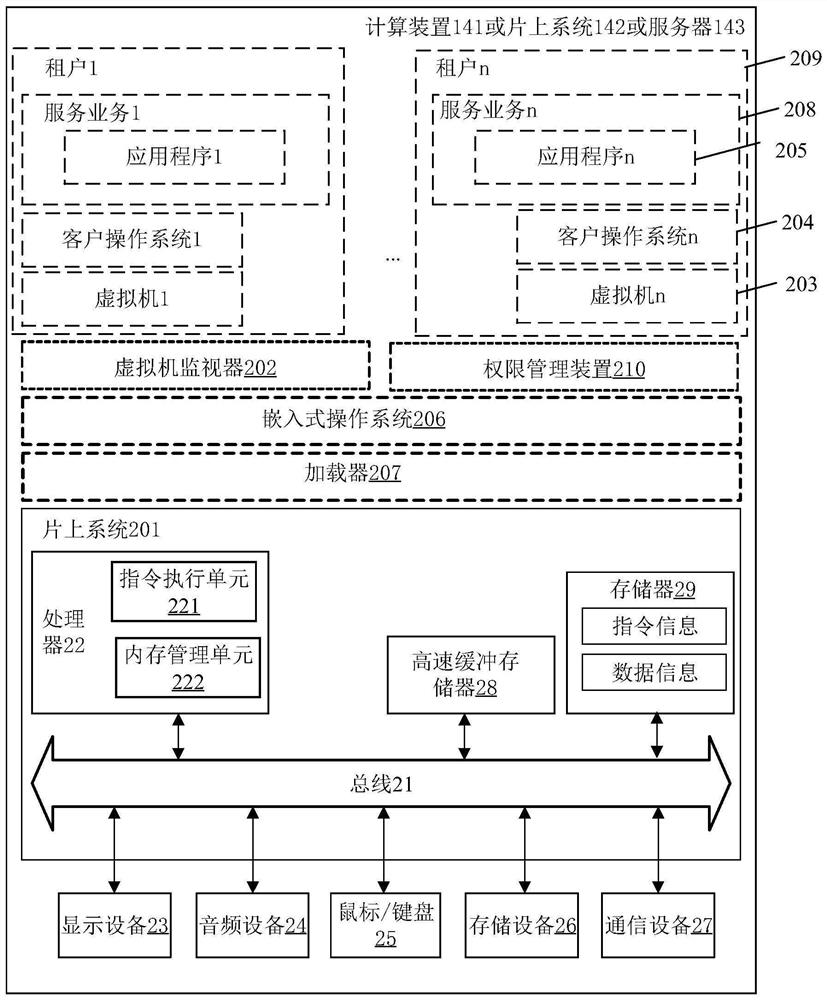

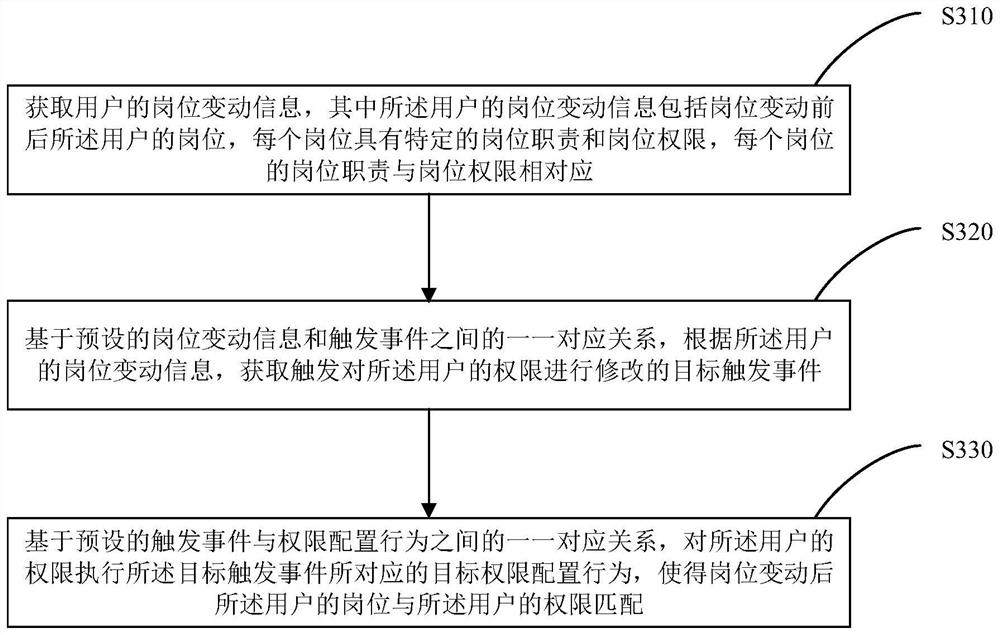

Authority management method, related device and medium

PendingCN114817901ALittle artificial dependenceReduce labor costsDigital data authenticationOffice automationInternet privacyEvent trigger

The invention provides an authority management method, a related device and a medium. The authority management method comprises the steps that post change information of a user is acquired, the post change information of the user comprises posts of the user before and after post change, each post has specific post responsibility and post authority, and the post responsibility of each post corresponds to the post authority; based on a preset one-to-one correspondence relationship between post change information and trigger events, according to the post change information of the user, obtaining a target trigger event triggering modification of the authority of the user; and based on a one-to-one correspondence relationship between a preset trigger event and a permission configuration behavior, executing a target permission configuration behavior corresponding to the target trigger event on the permission of the user, so that the post of the user is matched with the permission of the user after the post is changed. According to the embodiment of the invention, the authority management efficiency and accuracy are improved, and the labor cost is reduced.

Owner:ALIBABA (CHINA) CO LTD

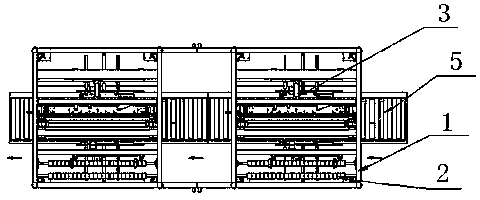

Molding and sizing integrated production line for quick-frozen prepared food

ActiveCN104351936AIncrease productivityHigh degree of automationFood shapingProduction lineMolding machine

The invention discloses a molding and sizing integrated production line for quick-frozen prepared food. The molding and sizing integrated production line comprises a stand, a case, a conveying mechanism, a molding mechanism, a sizing mechanism and two sets of energy saving mechanisms, wherein the case, the conveying mechanism, the molding mechanism, the sizing mechanism and the two sets of energy saving mechanisms are arranged on the stand; a trough plate chain arranged on the molding mechanism is formed by a plurality of groups of trough plates which are sequentially arranged on the conveying mechanism; one or more group(s) of grouting die head(s) is / are arranged on the stand and above the trough plate chain; discharge hole(s) of the one or more group(s) of grouting die head(s) is / are inserted into the trough plates arranged at the front end of the trough plate chain. According to the molding and sizing integrated production line, the trough plate chain is formed by the plurality of groups of trough plates which are sequentially arranged on the conveying mechanism, and the trough shapes of the trough plates are in one or multiple shape(s) in semicircular shape, triangle or flower bud shape, so that food with multiple shapes can be produced for once under the action of the sizing mechanism; the molding and sizing integrated production line is high in degree of automation and high in production efficiency.

Owner:FUJIAN ANJOY FOODS CO LTD +3

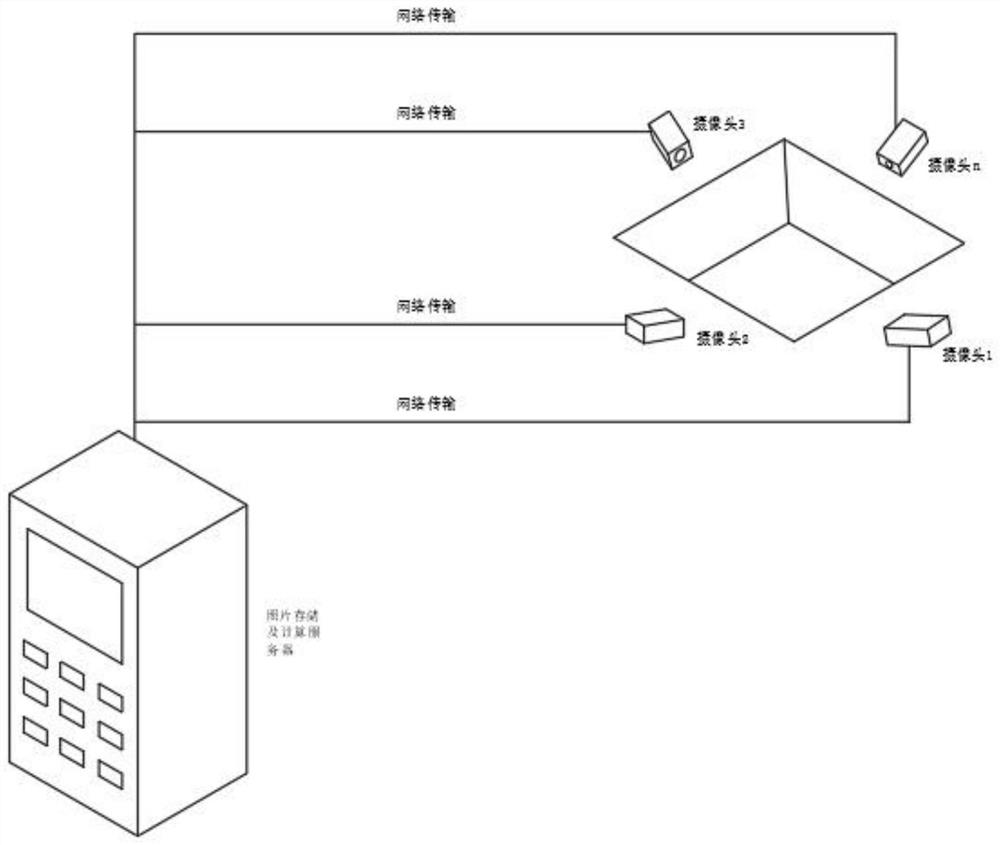

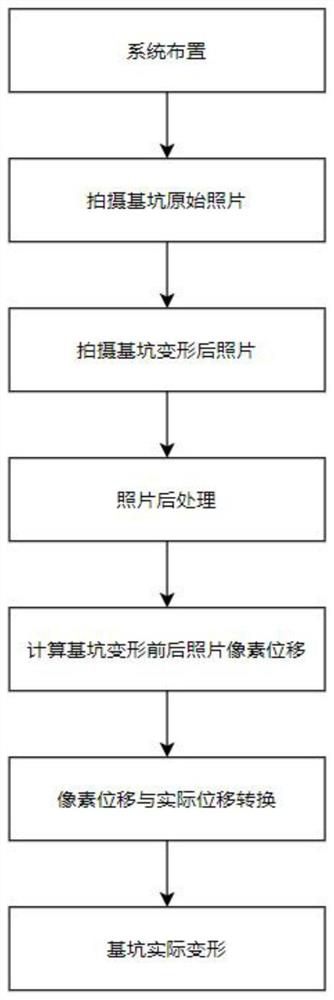

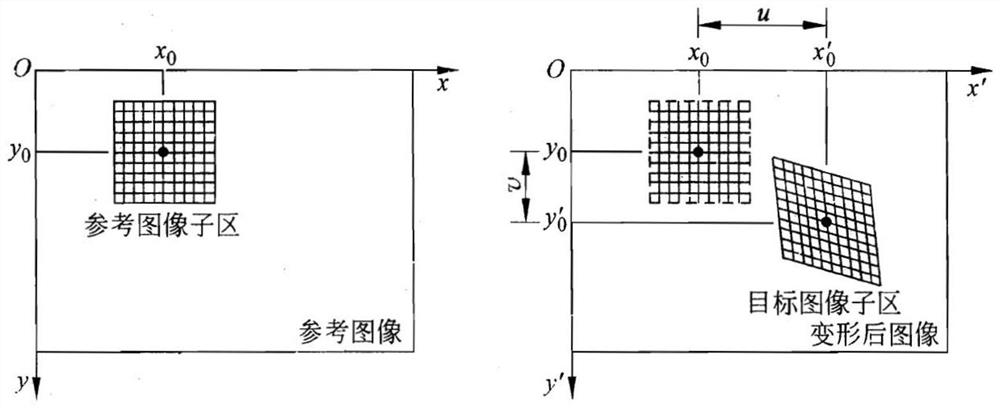

Foundation pit deformation intelligent monitoring method and system

PendingCN114197546AAvoiding the number of operations on the edge of the foundation pitEasy to buyImage analysisFoundation testingVideo monitoringComputer graphics (images)

The invention discloses an intelligent monitoring method and system for deformation of a foundation pit, and the method comprises the following steps: S1, arranging a small number of network video monitoring cameras outside a settlement influence range at the periphery of the foundation pit according to the size and shape of the foundation pit, and taking pictures of deformation of the foundation pit; s2, after each camera is erected, taking an initial picture as an original reference, and independently transmitting the initial picture to a server for storage through a wireless network; and S3, in the foundation pit monitoring process, according to monitoring needs, each monitoring camera shoots a foundation pit deformation process picture at regular intervals, and independently transmits the picture to the server for storage through the wireless network. According to the method, the pictures of the same part of the foundation pit at different moments are compared and calculated through related search, an integer pixel search algorithm and a sub-pixel interpolation algorithm on a server, the displacement of image pixel points between the different pictures is obtained, and the displacement of the pixel points between the pictures is converted into actual deformation of the foundation pit through a conversion coefficient.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

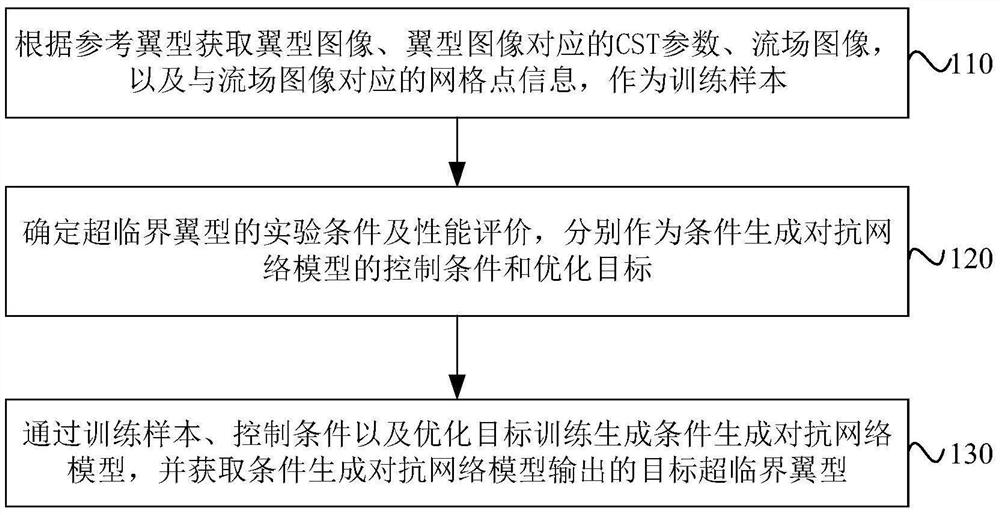

Supercritical airfoil profile generation method and device, electronic equipment and storage medium

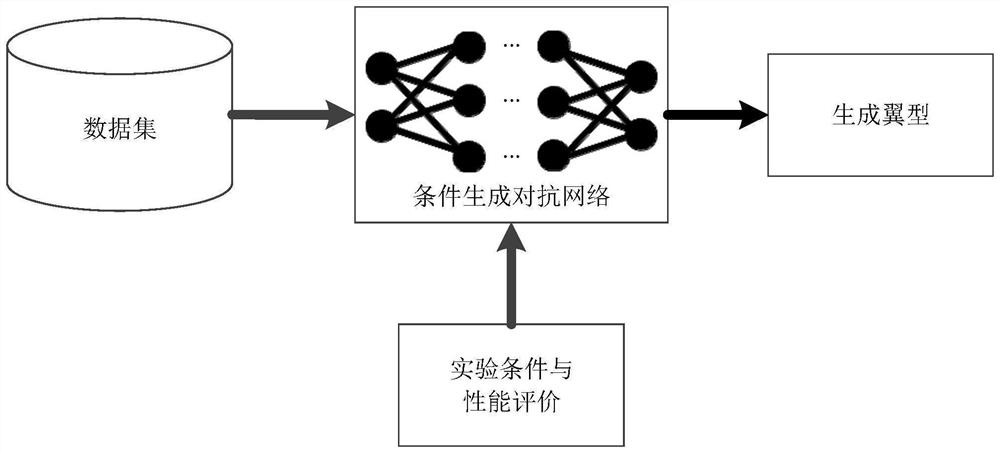

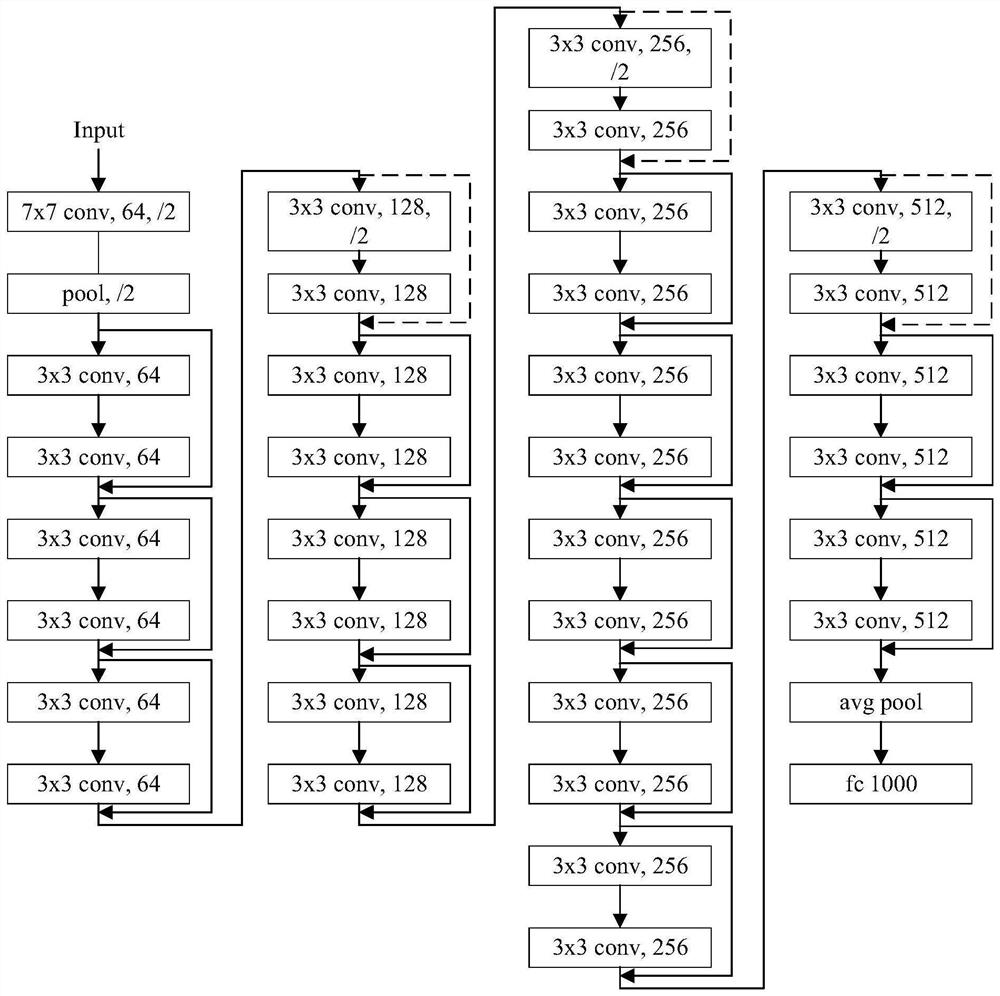

PendingCN114692488AShorten the design cycleImprove smoothnessGeometric CADCharacter and pattern recognitionAlgorithmSimulation

The embodiment of the invention discloses a supercritical airfoil profile generation method and device, electronic equipment and a storage medium. The method comprises the following steps: acquiring a basic airfoil profile image, a CST parameter corresponding to the airfoil profile image, a flow field image and grid point information corresponding to the flow field image according to a reference airfoil profile as training samples; experimental conditions and performance evaluation of the supercritical airfoil profile are determined and serve as control conditions and optimization targets of the conditional generative adversarial network model respectively; a conditional generative adversarial network model is generated through training of the training samples and the control conditions, and a target supercritical airfoil profile output by the conditional generative adversarial network model is obtained and optimized. According to the method, the airfoil design period can be shortened, the wind tunnel test frequency is reduced, the research and development cost is reduced, the manual dependence is reduced, and the airfoil smoothness is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

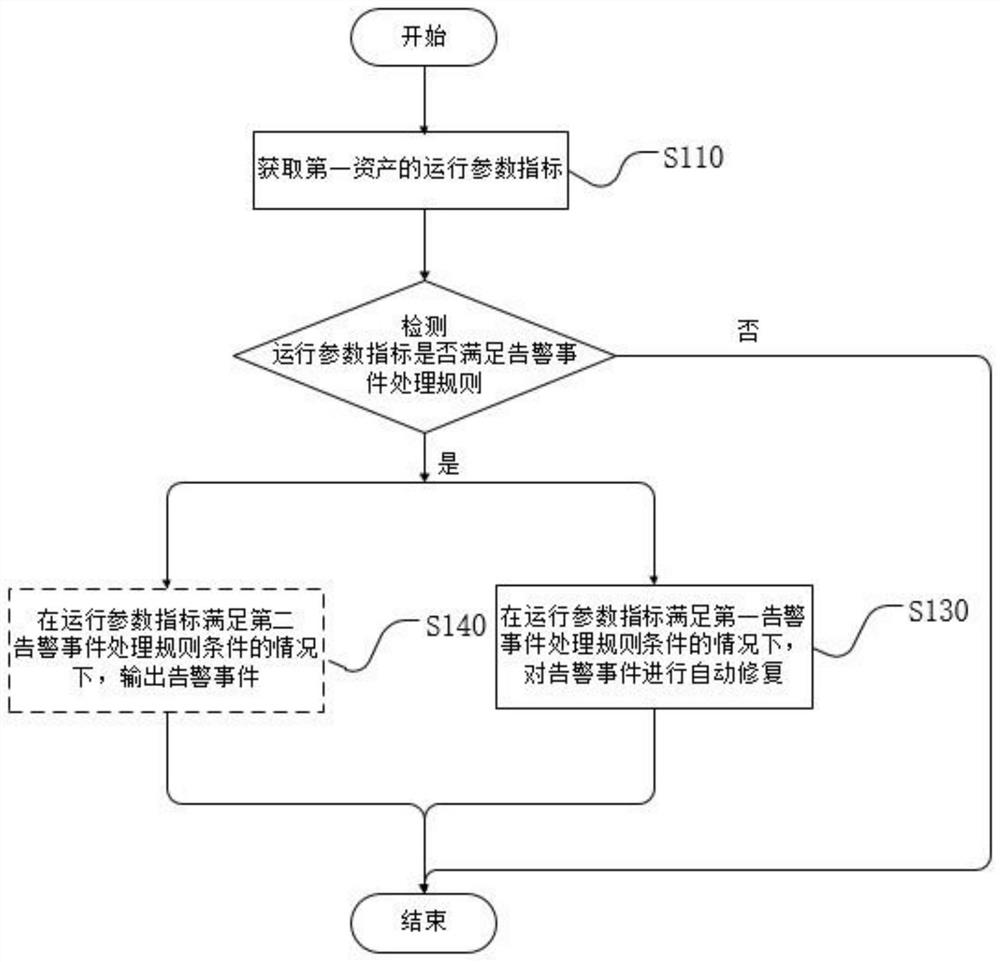

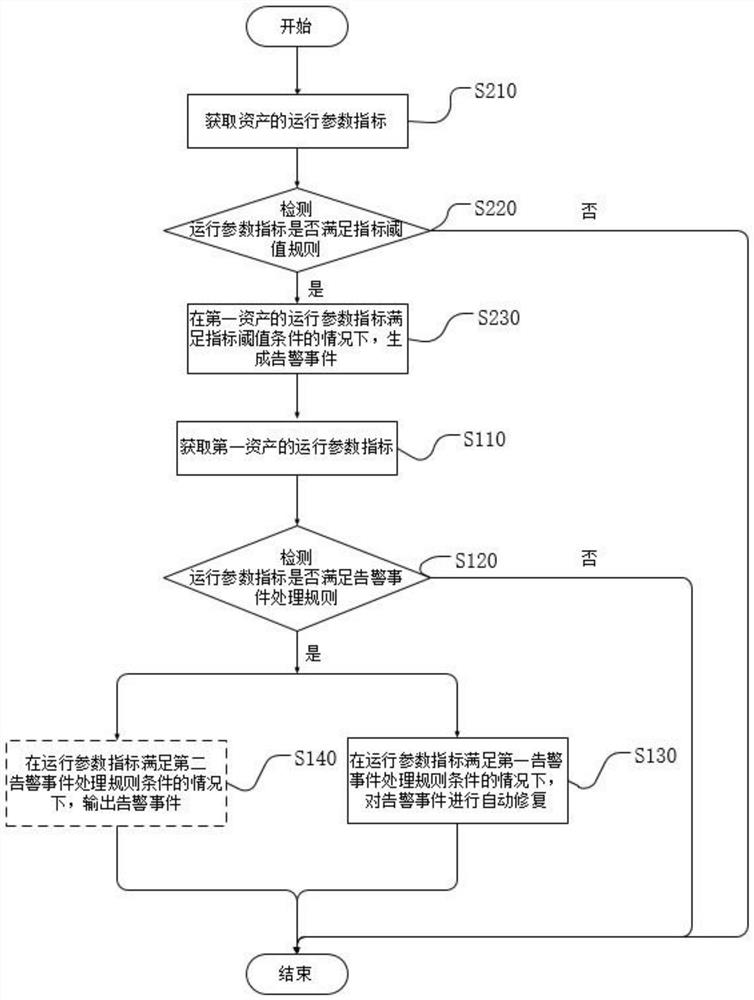

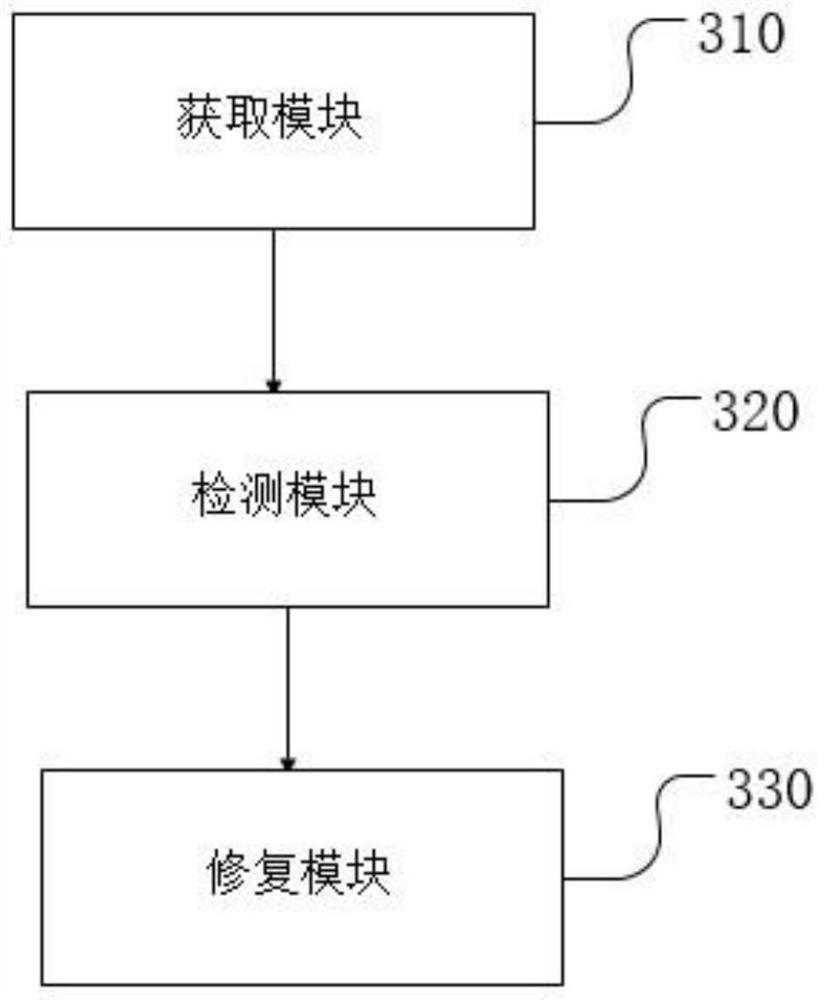

Alarm event processing method, device and equipment and computer storage medium

PendingCN114331046ALittle artificial dependenceImprove operation and maintenance efficiencyOffice automationResourcesReliability engineeringReal-time computing

The invention discloses an alarm event processing method, apparatus and device, and a computer storage medium. The method comprises the steps of obtaining an operation parameter index of a first asset; the first assets are assets in which an alarm event occurs in the operation and maintenance system; based on the operation parameter index, detecting whether the operation parameter index meets an alarm event processing rule; and under the condition that the operation parameter index meets a first alarm event processing rule condition, automatically repairing the alarm event. According to the embodiment of the invention, the manual dependence of system operation and maintenance can be effectively reduced, the operation and maintenance efficiency is improved, and the manual operation and maintenance cost and the operation and maintenance time are saved.

Owner:天云软件技术有限公司

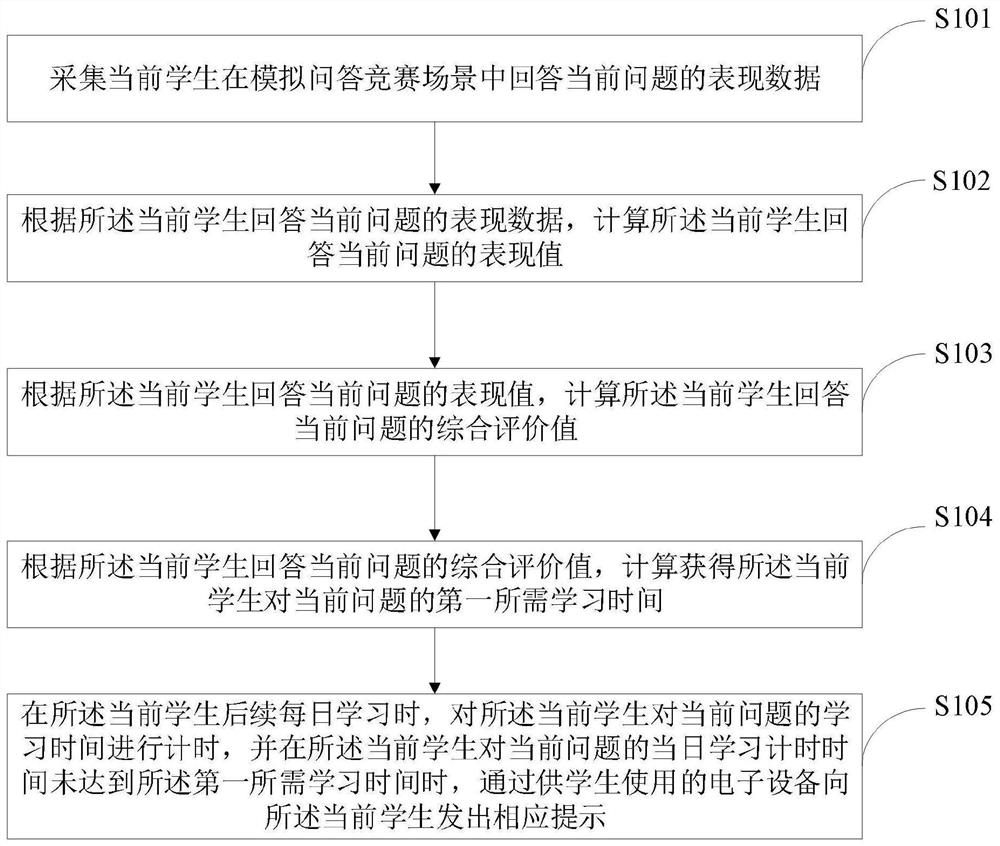

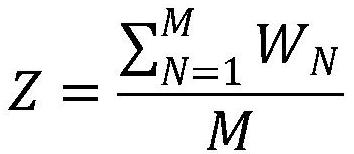

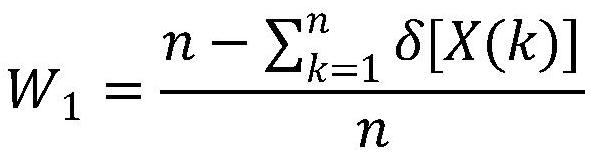

Student simulation competition evaluation control method based on virtual reality scene

PendingCN113139742AImprove competition abilityImprove mental fitnessResourcesEngineeringQuestions and answers

The invention discloses a student simulation competition evaluation control method based on a virtual reality scene, and relates to the technical field of intelligent learning. The method comprises the steps of collecting performance data of a current student for answering a current question in a simulated question and answer competition scene; according to the performance data of the current question answered by the current student, calculating a performance value of the current question answered by the current student; calculating a comprehensive evaluation value of the current question answered by the current student according to the performance value of the current question answered by the current student; according to the comprehensive evaluation value of the current question answered by the current student, calculating to obtain first required learning time of the current student for the current question; and sending a corresponding prompt to the current student when the current student performs subsequent daily learning and the current learning time of the current student for the current question does not reach the first required learning time. According to the invention, personalized suggestions of subsequent learning time can be given according to learning conditions of different students for different questions.

Owner:SHANGHAI SQUIRREL CLASSROOM ARTIFICIAL INTELLIGENCE TECH CO LTD

A hybrid core molding process

ActiveCN107350429BSlow down depreciationIncrease the number ofAdditive manufacturing apparatusFoundry mouldsUltimate tensile strengthProduct Part

The invention discloses a mixed child-mother core assembly molding technology. A 3D printing molding technology and a sand mixing molding technology are combined, a part which is close to a product part having a plurality of structural features adopts 3D printing, and the other parts which have less structural features adopt the traditional sand mixing molding technology method, therefore an assembled sand mold which works through cooperative using of a mother core and a child core is formed. Based on the advantages of an original 3D printing molding technology, a traditional sand mixer production technology is introduced, the two molding technologies are combined with each other, further the cost of raw materials and the equipment investment cost are lowered, and meanwhile, child-mother separated core combination is conducted on a sand molding part which is brought out of a casting and the mold thickness which is brought out of a casting system and improves the strength so as to widen thinking for later multi-technology combination; the number of castings in a single sand box is increased, the sand box utilization ratio and the production efficiency are improved, the dependence on manual work is reduced at the same time, the cost of 3D printing raw materials and the depreciation of the equipment are reduced, and meanwhile, waste of molten iron is avoided, and the purposes of cost reduction and efficiency improvement are achieved.

Owner:四川共享铸造有限公司

A kind of manufacturing method of composite lightweight filling member

A manufacturing method for a composite light filling component comprises the steps as follows: prefabricating a light internal mold; buckling the light internal mold; fixing the light internal mold; making a mixture of cement, mortar and glue; performing surface pretreatment, that is, spreading the mixture of the cement, the mortar and the glue, which is stirred well and in a semifluid state, onto the upper surface of the light internal mold; wrapping the light internal mold with a fiberglass mesh; performing surface treatment, that is, spreading the mixture of cement, mortar and glue, which is in the semifluid state, onto the lower surface and the peripheral side surface of the light internal mold to cover the fiberglass mesh; performing curing, that is, turning over the light internal mold after the mixture of the cement, the mortar and the glue on the lower surface is solidified and cured, and finally enabling the mixture of the cement, the mortar and the glue to form a hard inorganic composite layer on the outer surface of the light internal mold. The manufacturing method for the composite light filling component, provided by the invention, is simple, fast and reasonable in technological process; the composite light filling component manufactured according to the manufacturing method is reasonable in product structure, convenient for production and transportation and convenient and fast in construction.

Owner:刘青云

A method of manufacturing a split lightweight filling component

The invention discloses a manufacturing method for a split-type lightweight filling component. The manufacturing method comprises the following steps: prefabricating a lightweight inner mold; mixing a mixture of cement, mortar and glue; performing surface pretreatment, coating the upper surfaces of polystyrene box bodies with the mixed mixture of the cement, the mortar and the glue in a semi-fluid state; wrapping a fiber glass net; performing surface treatment, coating the peripheral side surfaces of each polystyrene box body with the mixture of the cement, the mortar and the glue in the semi-fluid state; covering the fiber glass net; hardening and curing; splitting the lightweight inner mold, aligning the positions of the lower surfaces of the two hardened and cured polystyrene box bodies, bundling the two hardened and cured polystyrene box bodies in a crossed way by using a plastic tape, and tightening a locking buckle on the plastic tape to split a complete split-type lightweight filling component. The manufacturing method for the composite lightweight filling component disclosed by the invention has the advantages that the simple, convenient and reasonable process flow is realized; a composite lightweight filling component product produced by the manufacturing method is reasonable in structure, convenient to produce and transport, and convenient to construct.

Owner:刘青云

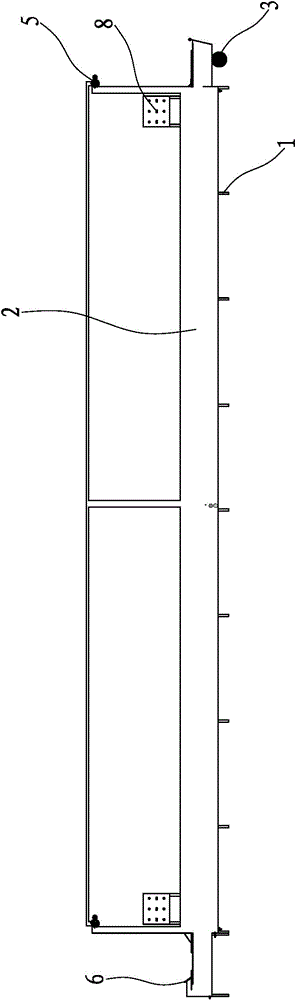

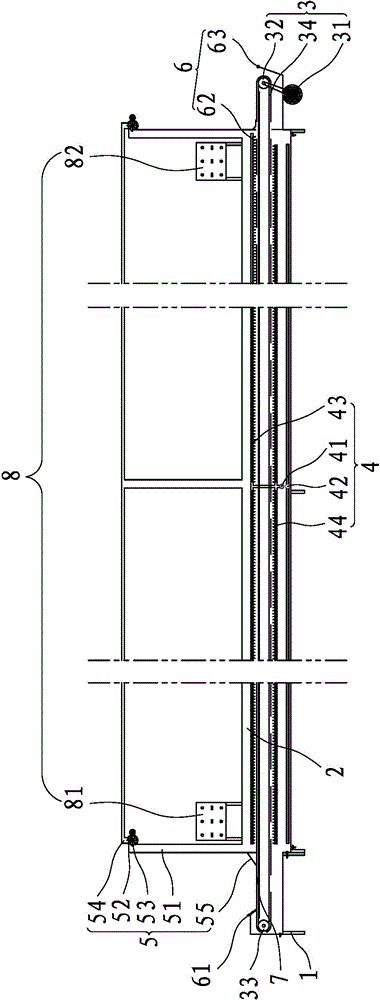

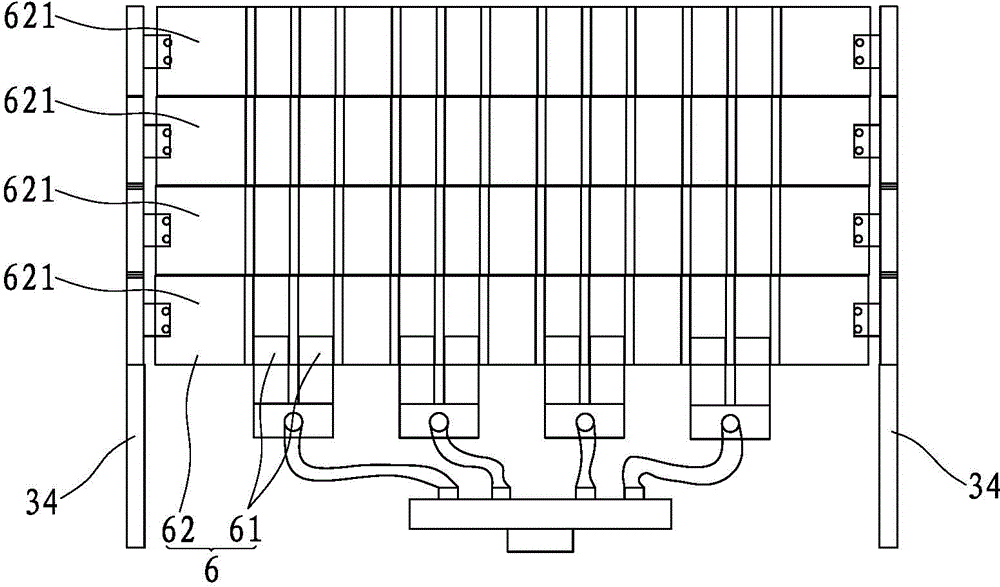

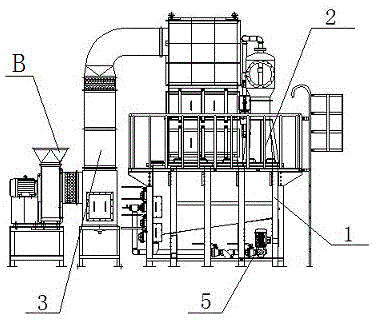

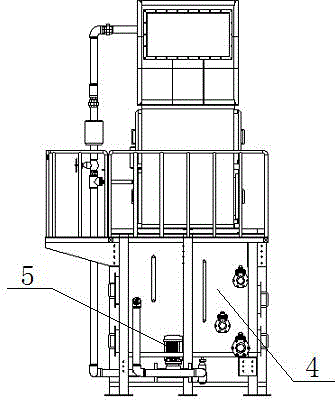

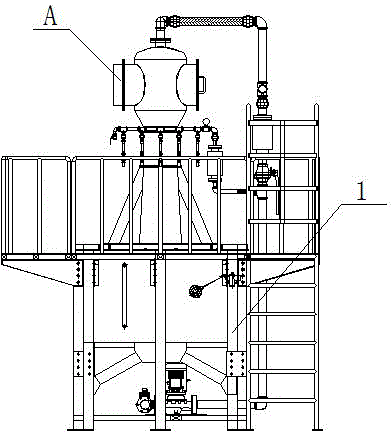

Large-scale equipment for filtering air odor and pollutant

InactiveCN103349896BLarge amount of processingSimple structureCombination devicesAutomatic controlWater vapor

The invention discloses large-scale equipment for filtering air odor and pollutant, which comprises an equipment frame body (1), a mass transfer reaction section (2) provided with an air inlet (A), a water-vapor separation section (3) provided with an air outlet (B) and a purification circulating water tank (4), wherein the mass transfer reaction section (2) provided with the air inlet (A) is mounted on the right side of the equipment frame body (1), the water-vapor separation section (3) provided with the air outlet (B) is mounted on the left side of the equipment frame body (1), and the purification circulating water tank (4) is mounted on the inner side of the equipment frame body (1). According to the large-scale equipment for filtering air odor and pollutant, the structure is simple and reasonable, the waste gas processing effect is excellent, other complex mechanisms and elements are not needed, the mechanical performance is stable, the operation cost is low, the automatic control degree is high, the operation is simple and convenient, the dependence on manpower is less, the stand-alone processing capability is strong and the processing capacity is huge.

Owner:DALIAN JIALIN EQUIP MFG

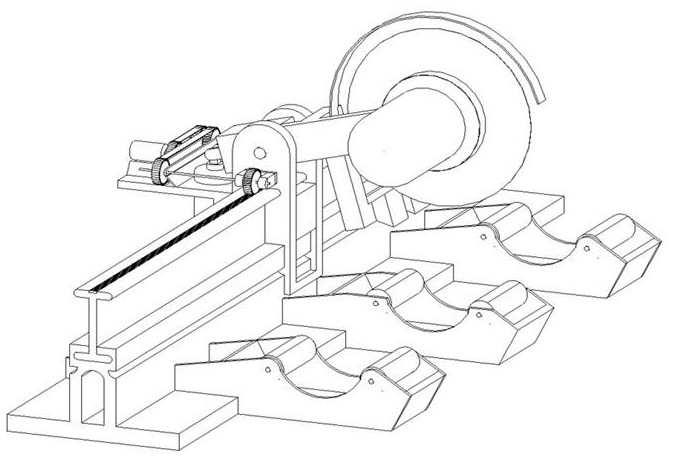

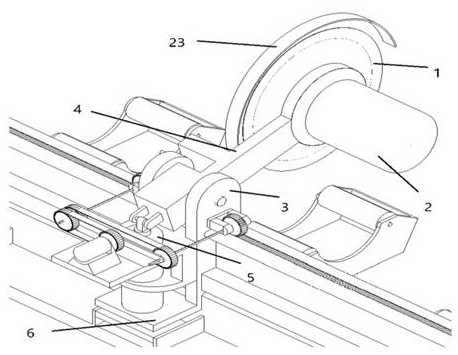

Movable fixed base monorail hydraulic pipe cutting device

InactiveCN111318755BEfficient automatic cuttingImprove pipeline identificationMetal sawing devicesMetal sawing accessoriesFire protectionArchitectural engineering

The invention discloses a movable fixed base monorail hydraulic pipeline cutting device. Including: ordinary hydraulic pipe cutting machine system, intelligent wiring system for building fire protection pipelines, mortise joint movable guide rail and guide rail bottom support system, pipe cutting machine data reception and automatic movement and power system, two-dimensional code and fire protection logo spraying system. The present invention takes an ordinary hydraulic pipe cutting machine as the main body and is equipped with an intelligent wiring system for fire-fighting pipes in buildings. It can automatically obtain the pipe length data from the electronic drawings of the construction project to automatically find the cutting position for intelligent cutting of the pipes, reducing manual dependence. Labor costs can be saved, and the building information model can also be used to identify the work synchronously, automatically generate the identity information of the pipelines at each installation site, and use the two-dimensional code and the fire-fighting marking spraying system for marking to improve the efficiency of subsequent pipeline assembly.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

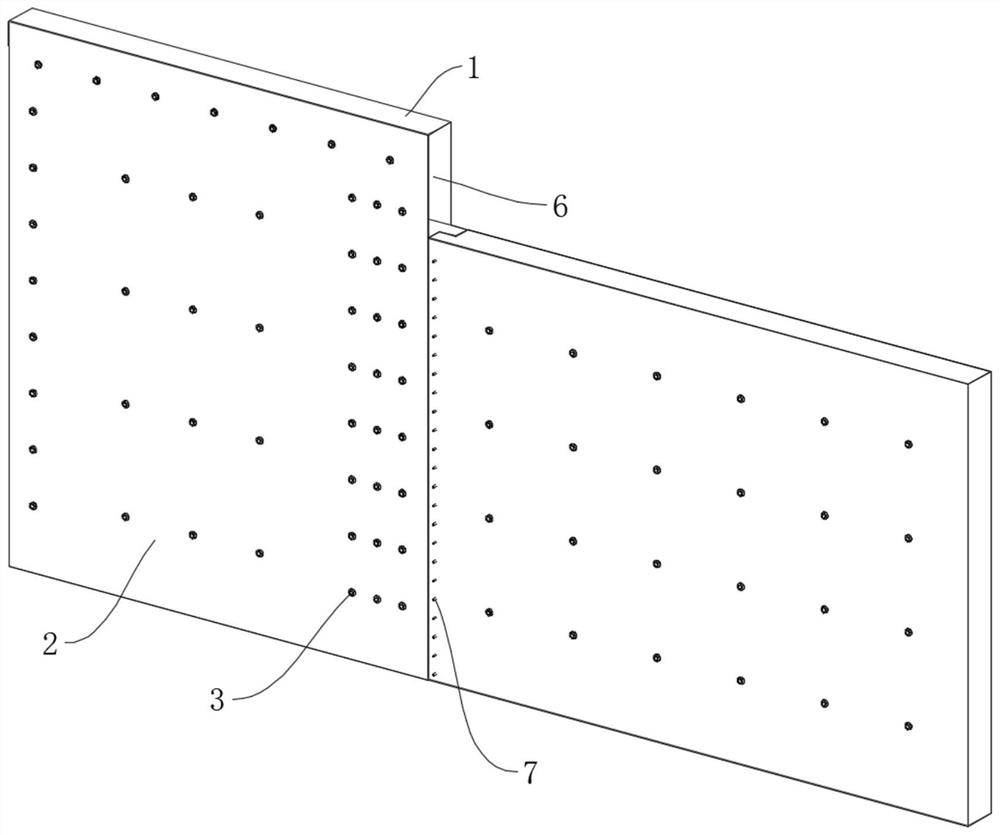

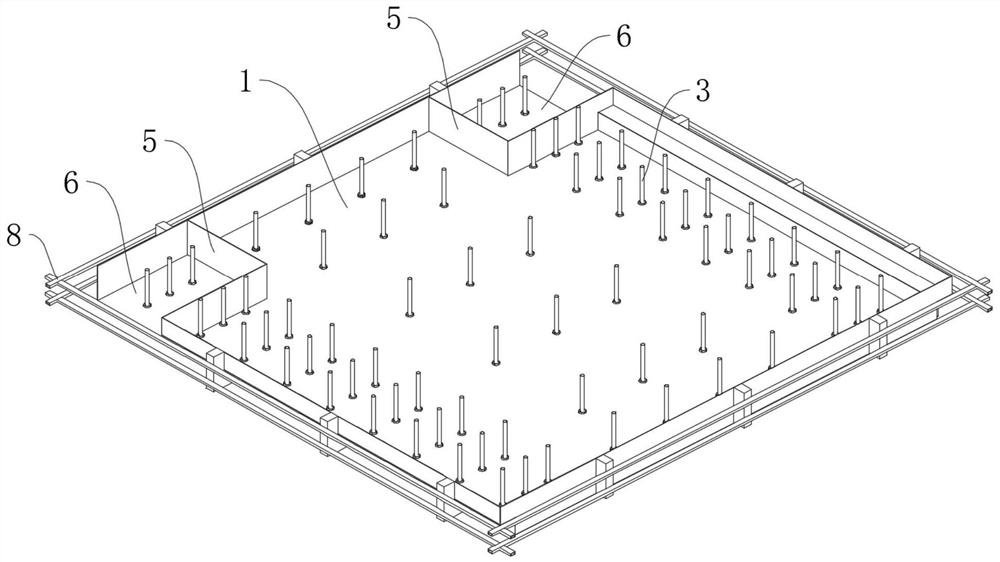

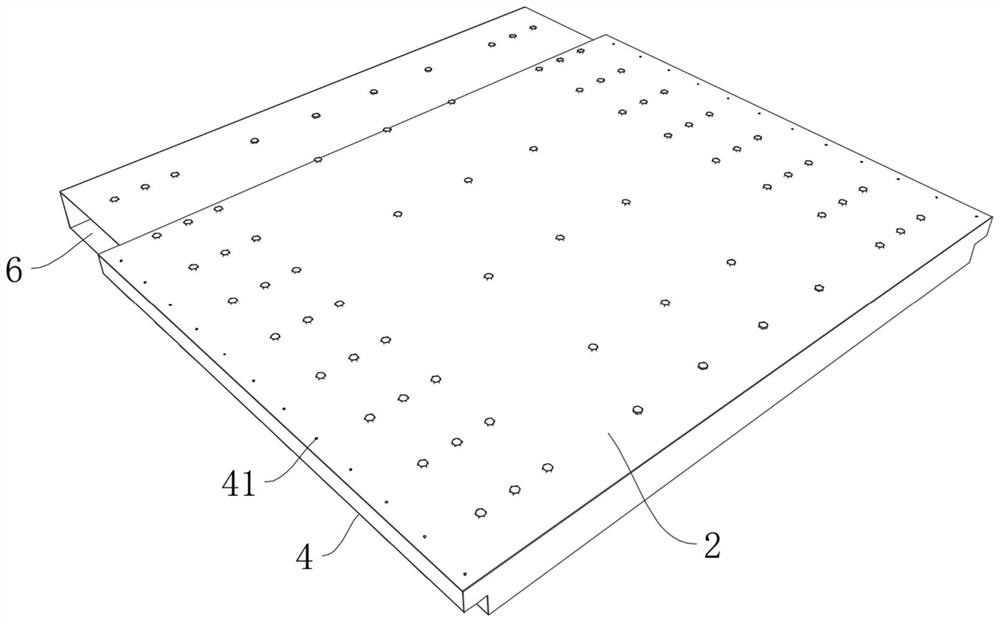

Fully-fabricated combined wallboard suitable for building industrialization and production method

PendingCN114876121ALittle artificial dependenceSimple structureConstruction materialWallsArchitectural engineeringRebar

The invention discloses a fully fabricated combined wallboard suitable for building industrialization, which comprises a wallboard body, the wallboard body comprises concrete and an outer covering steel plate wrapping the concrete, the outer covering steel plate comprises a first plate body, a second plate body and a plurality of split bolts, the first plate body is box-shaped, the second plate body is plate-shaped, and the split bolts are arranged on the first plate body and the second plate body. The first plate body and the second plate body are matched with each other to wrap the concrete, and the multiple split bolts penetrate through the first plate body, the concrete and the second plate body to connect the first plate body, the concrete and the second plate body together to be integrally and cooperatively stressed. The first plate body, the second plate body and the split bolts are used for replacing a traditional steel reinforcement cage, a series of procedures such as steel bar binding and mold assembling which need manual participation and are highly dependent on manual work are omitted, the dependency degree of the whole component on manual work is greatly reduced, the structure is simple, and industrial and automatic production is facilitated. Meanwhile, when the wallboard body is used as an infilled wall, internal concrete can be made of green solid waste resource materials, and low carbon and environmental protection are achieved.

Owner:中建三局科创发展(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com