Double-layer bagging equipment in carton

A technology of double-layer sleeves and cartons, which is applied in packaging and other directions, can solve the problems of large dependence on manual operation, heavy work, and low production efficiency, and achieve the effects of low manual dependence, high work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

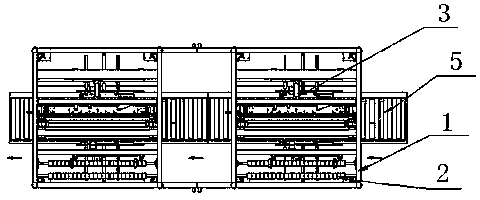

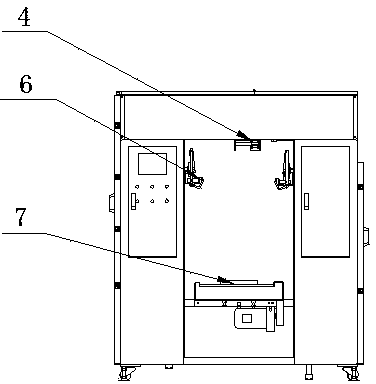

[0023] Such as figure 1 , figure 2 with image 3 As shown, the double-layer bagging equipment inside the carton includes the main frame body 1, the film storage frame, the film feeding mechanism 2, the plastic film clamping mechanism 3, the cutting mechanism 4, the packaging conveyor 5 and the film guiding mechanism, and the film storage frame is installed At the lower part of one side of the main frame body 1, the film feeding mechanism 2 is installed above the film storage rack, and the main frame body 1 spans above the packaging conveyor 5, and the packaging conveyor 5 is arranged inside the main frame body 1 and passes through the main frame body 1, the plastic film clamping mechanism 3, the cutting mechanism 4 and the film guiding mechanism are respectively fixed on the main frame body 1, the front end of the plastic film clamping mechanism 3 is equipped with a suction cup 6, and the upper side of the plastic film clamping mechanism 3 is equipped with a heat sink. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com