On-line evaluation system and method for operation, maintenance and fault monitoring of hydropower station hoisting equipment

A fault monitoring and operation and maintenance system technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as easy to ignore equipment maintenance and maintenance, hidden safety hazards, frequent equipment failures, etc., to facilitate modern management and ensure reliable operation , The effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

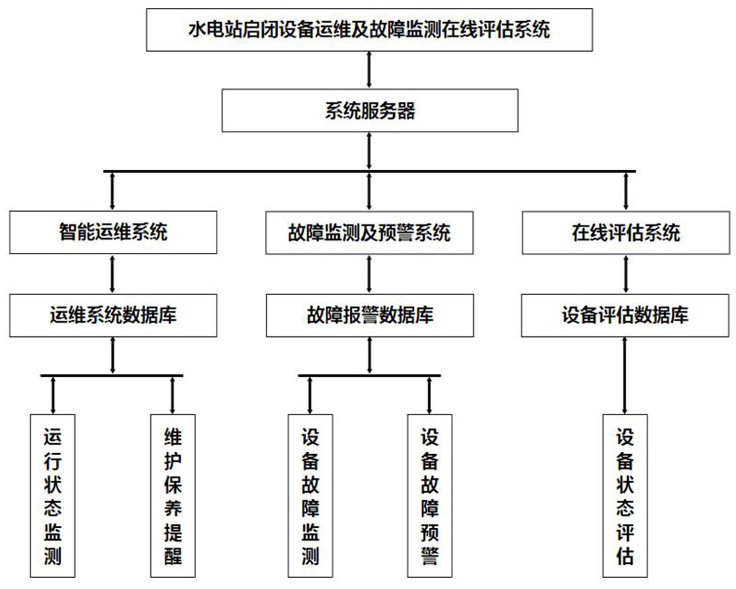

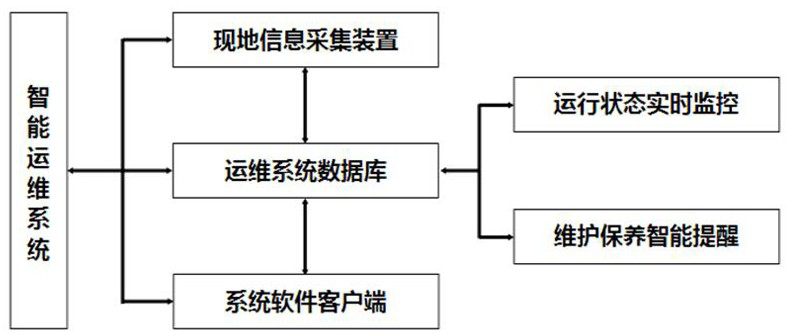

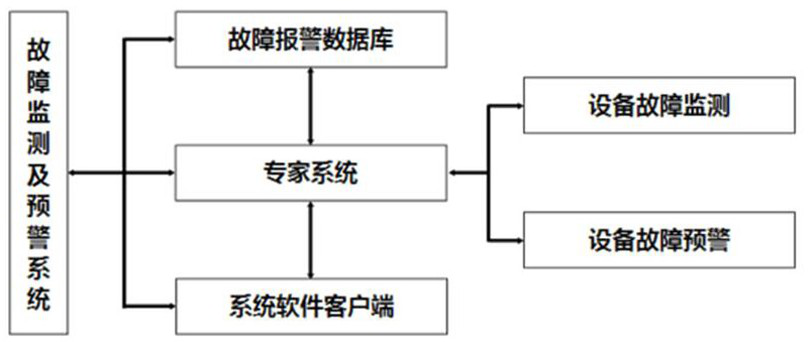

[0031] The system of the hydropower station hoisting equipment operation and maintenance and fault monitoring online evaluation system of the present invention includes three subsystems, such as figure 1 As shown, it includes: (1) intelligent operation and maintenance system; (2) fault monitoring and early warning system; (3) online evaluation system. The three subsystems run in the system server as three functional modules implemented by software. The three subsystems are the three major functional modules of the entire system. Server connection, the human-computer interaction module includes but not limited to monitors and keyboards, or touch screens. The system of the present invention can be designed based on the B / S architecture, which ensures that the client human-computer interaction module can display the three subsystems of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com