Duplicate gear riveting method

A duplex gear and riveting technology, which is applied in the field of gears, can solve the problems of large main shaft vibration, uneven edges of the central shaft, burrs, etc., and achieve the effect of small main shaft vibration, smooth appearance and high coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

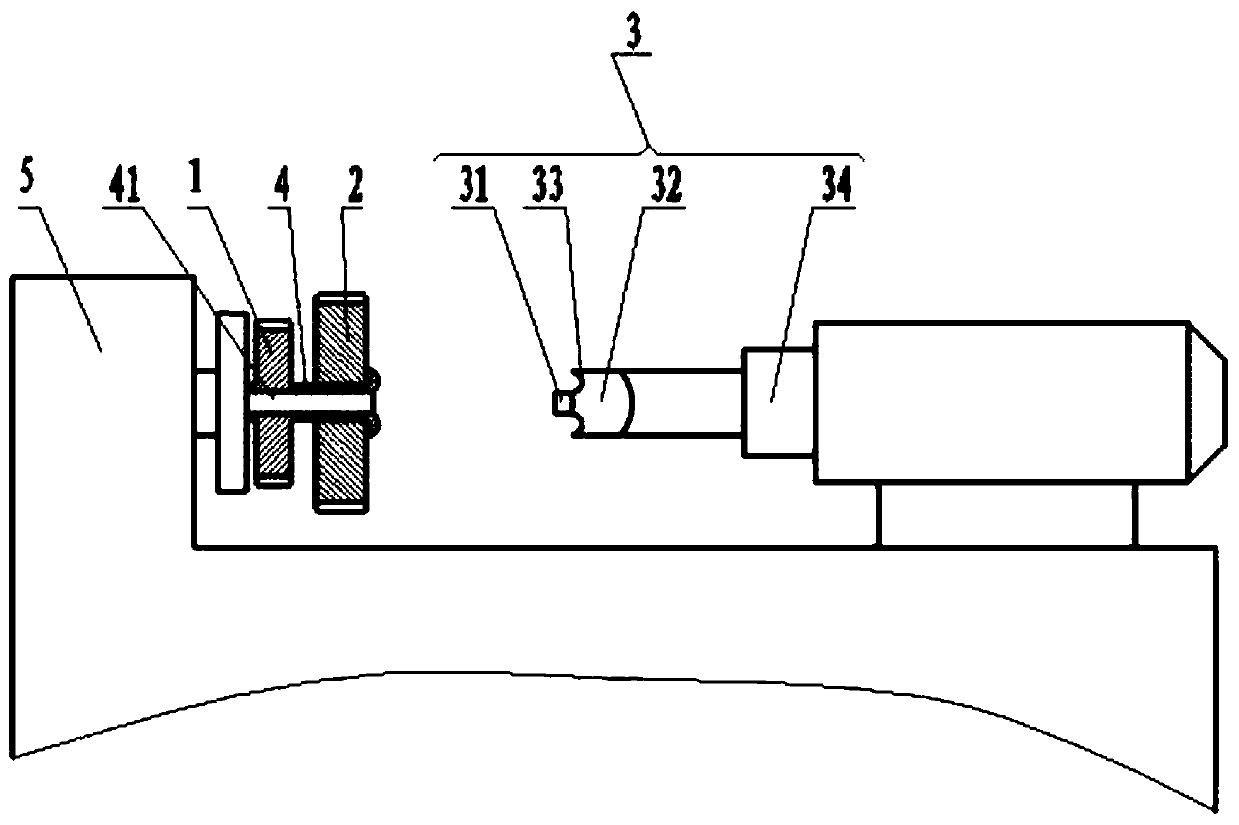

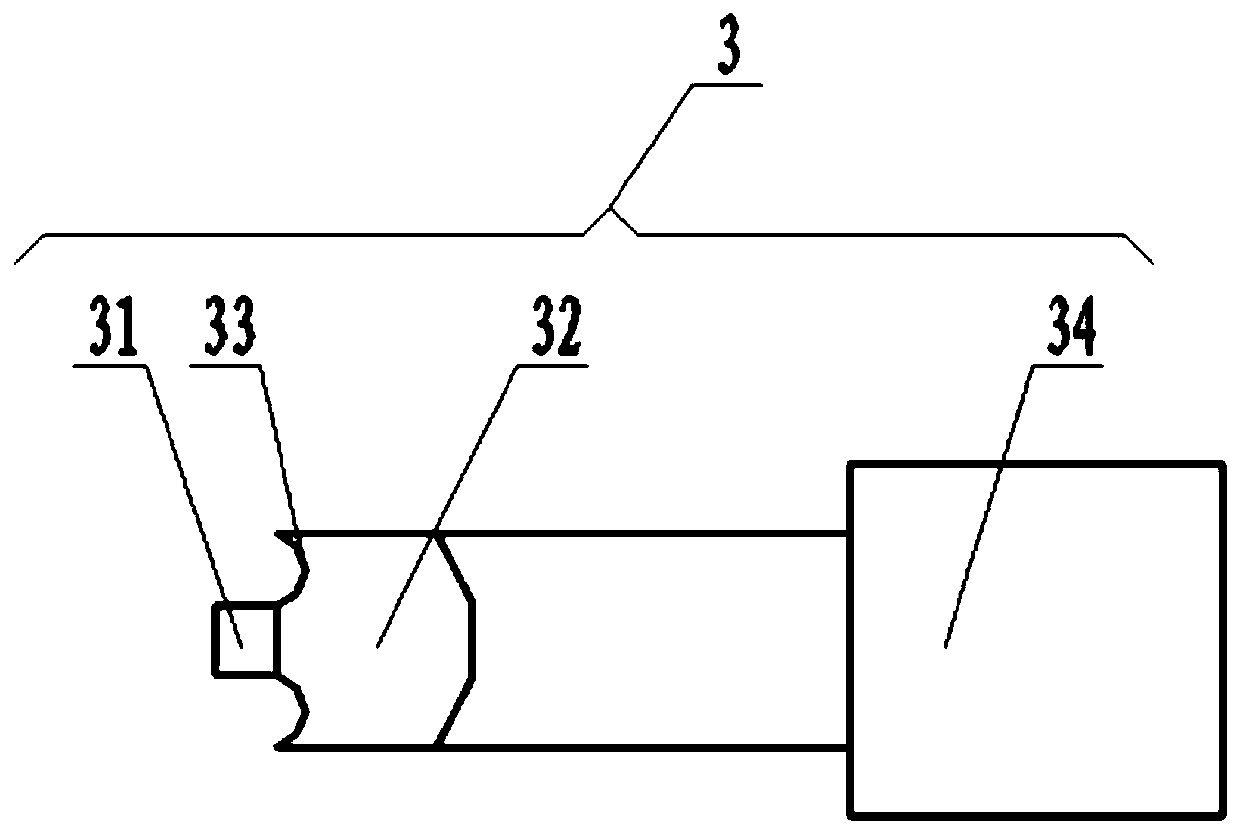

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a double gear riveting method, comprising the following steps:

[0027] Step 1: Provide gear A1, gear B2 and riveting head 3, gear A1 is fixedly connected to the central shaft 4 and the left and right ends of the central shaft 4 extend beyond the left and right sides of the gear A1, and the central shaft 4 is provided with a through The through holes 41 at the left and right ends, and the riveting head 3 include a cylindrical guide post 31;

[0028] Step 2: First clamp one end of the central shaft 4 in step 1 on the main shaft of the lathe 5, and then fix the gear B2 in step 1 to the other end of the central shaft 4;

[0029] Step 3: Start the lathe 5 to rotate the main shaft of the lathe 5. During the rotation of the main shaft of the lathe 5, fit the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com