A manufacturing process of prefabricated cement utility poles

A technology of cement utility poles and manufacturing process, which is applied to towers, building types, buildings, etc., can solve the problems of cumbersome fixing of the main reinforcement and difficulty in controlling the main reinforcement to form a circle, so as to improve the aesthetics of the structure and improve the ease of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

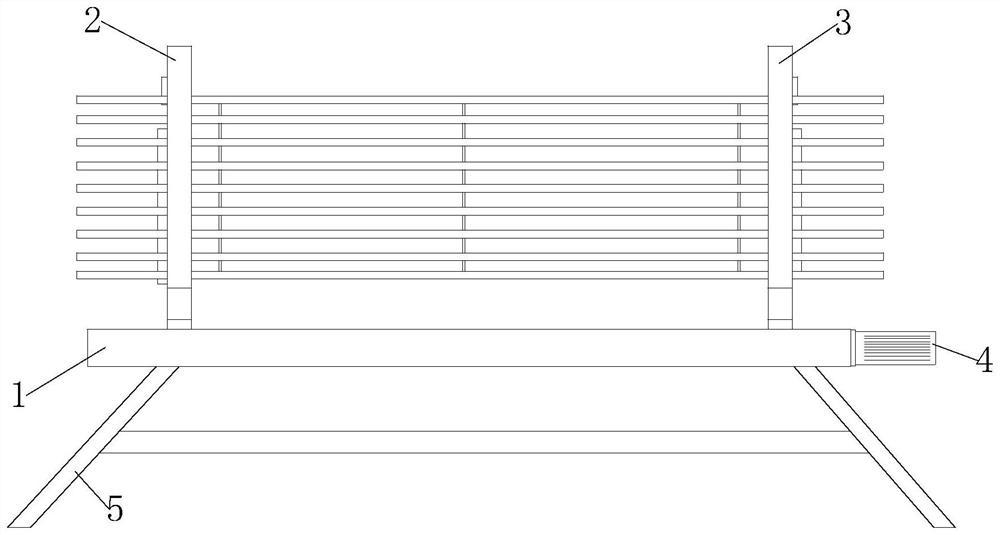

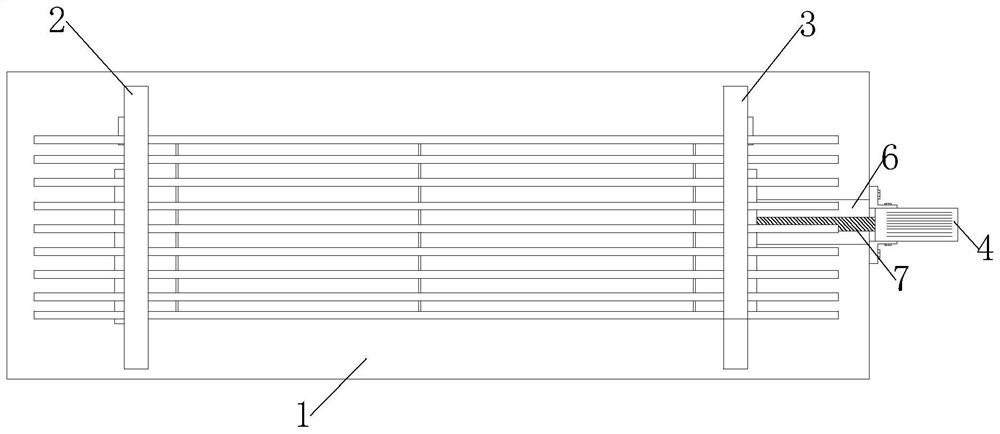

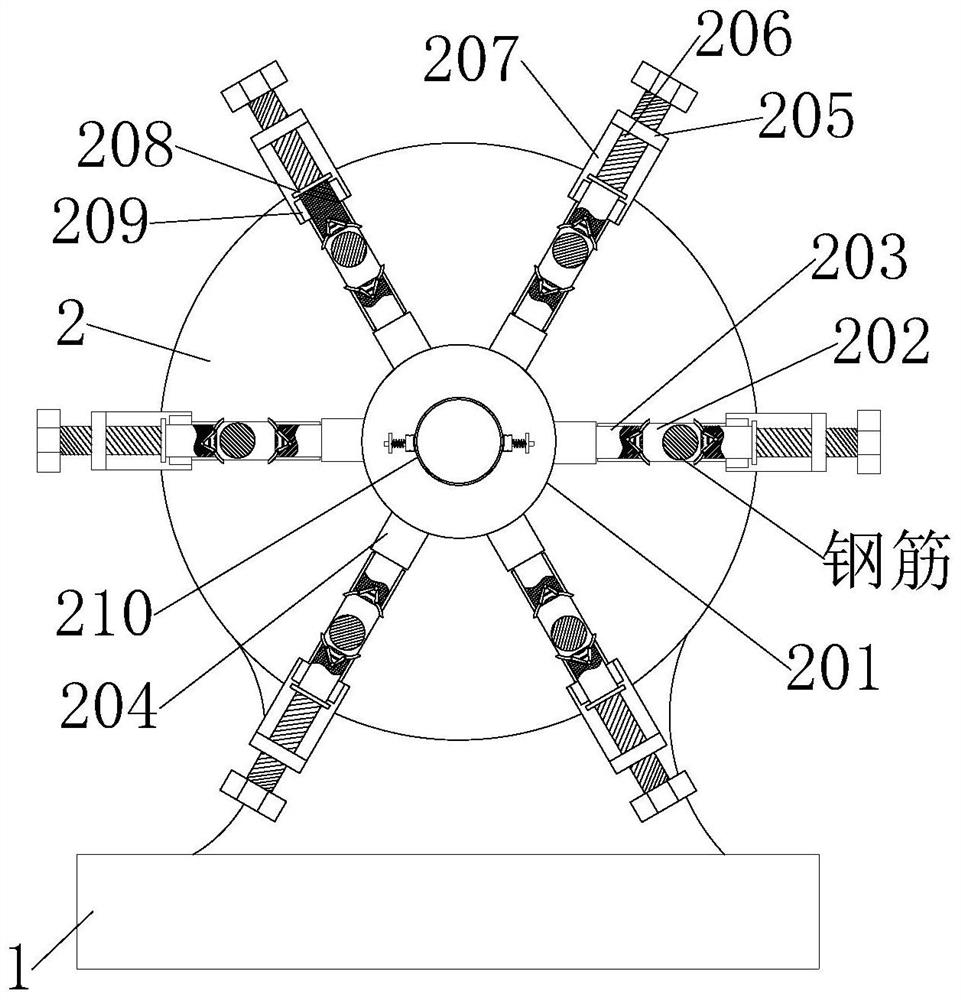

[0040] see Figure 1-8 , is a schematic diagram of the overall structure of a prefabricated cement utility pole manufacturing process.

[0041] A manufacturing process for prefabricated cement utility poles, comprising the following steps:

[0042] S1, material preparation, select two kinds of straight bar-shaped steel bars with different lengths as the reinforcement skeleton material for making cement utility poles, the long straight bar-shaped steel bar is used as the main bar, and the short straight bar-shaped steel bar is used as the stirrup;

[0043] S2, the skeleton is fixed, and the plurality of straight rod-shaped main reinforcements selected in step S1 are fixed at equal intervals, so that the plurality of straight rod-shaped main reinforcements are equally spaced to form a circle;

[0044] S3, skeleton welding, welding and fixing the main reinforcements surrounded by a circle at equal intervals in step S2, welded with stirrups perpendicular to the main reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com